Tower Crane TC6014 60M Max Working Range

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of TC6014 tower crane

Feature: Tower Crane

Condition: New

Max.Lifting Load: 8T

Span: 60m

Place of Origin: China(Mainland)

Model Number: TC6014

Packaging & Delivery of TC6014 tower crane

Packaging Detail: Nude package

Delivery Detail: 25-30days

Specifications of TC6014 tower crane

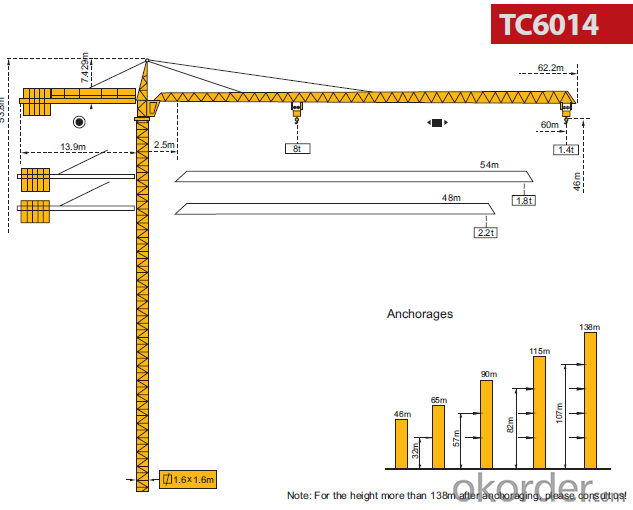

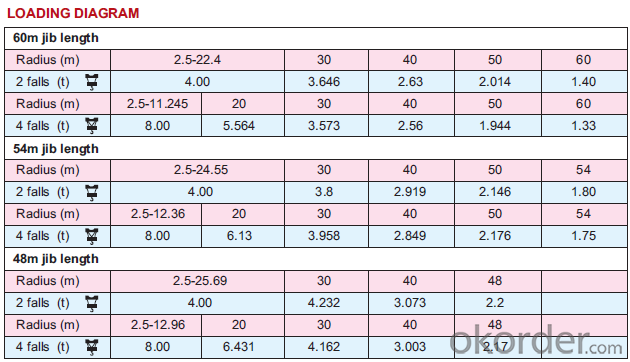

● Max. working range 60m, tip lifting weight 1.4T and Max. lifting weight 8T.

● Hoisting mechanism fitted with three speed moto stable braking and less shock when shifting.

● Slewing mechanism equipped with 4-speed moto stable and reliable can provide stepless speed regulation.

● Trolleying mechanism can provide two operation speeds

Independent height (m) | 46 | |||||

Max height with attachment (m) | 138(200) | |||||

Working range can be adjusted(m) | 48、54、60 | |||||

Min working range(m) | 2.5 | |||||

Max lifting capacity(t) | 8 | |||||

Tip load @ 60m(t) | 1.4 | |||||

Hoist mechanism | Falls | 2 | 4 | |||

Lifting capacity(t) | 0-2 | 0-4 | 0-4 | 0-8 | ||

Speed(m/min) | 0-80 | 0-40 | 0-40 | 0-20 | ||

Motor | YZRWFC250M-4/8 30/30KW | |||||

Trolleying mechanism | Speed(m/min) | 53/27/12 | ||||

Motor | YZTDE132L-4 /8/16 3.3/2.2/1.1KW | |||||

Slewing mechanism | Speed(r/min) | 0-0.6 | ||||

Motor | YZR132M2-6-3.7KW×2 | |||||

Climbing speed(m/min) | 0.5 | |||||

Counterweight(t) | 17.0 | |||||

Mast section size(L×W×H)m | 1.6×1.6×3.0 | |||||

Working temperature | -40-+60℃ | |||||

Total Power (KW) | 42 | |||||

Power supply requirement (KVA) | 190KVA for generator | |||||

Cable type ( within 35 meters from site power source to lower electric box of tower crane ) | 50mm2(3+2, 5 cores) | |||||

380V×95%=361V 179A | ||||||

Rated working voltage & current | 380V 128A | |||||

Images of TC6014 tower crane

FAQ of TC6014 tower crane

Q: What is the principal to quote the right tower crane to the client?

A: First, we need to know clients’ requirements. Normally the following information should be clarified by the client: max lifting capacity, height (height under hook), tip load and jib length.

Second, we need to know what the foundation requirement from the client is. (Fixed/undercarriage/ undercarriage with traveling system), mast section type (panel/integrated), power supply source (voltage, ampere and frequency), the distance between the machine and power supply……

Third if there are special needs, we could suggest proposal according to clear data provided by the clients. End-user, as construction machinery buyer, knows the site situation well and should make decision, such as the machinery specification, type…….

Q: What is 3 main mechanism of the tower crane?

A: there are trolleying mechanism/ slewing mechanism/ hoisting mechanism.

Q: Can you equip with light on tower crane jib, monitor, remote control and anemometer?

A: Sure. All of these could be provided with extra cost upon the clients’ requirements. But according to general practice, remote control is not suggested because most of the operator feedback operation in the cabin will provide a wide working view.

To Lead The Revoluation of International Trade

- Q: Please write in days, hours, weeks, etc.I need math help!!!!

- If it takes 7*60 + 11 = 431 seconds to make 1 crane, then making one million would take 431,000,000 seconds. There are 3600s*24hr*365.25d = 31,557,600 seconds in an average year. Dividing 431 million by this gives a little over 13 years, with a remainder of 20,751,200 seconds. There are 3600*24*30 = 2,592,000 seconds in an average month. So that gives 8 months with a remainder of 15,200 seconds. There are 3600 seconds in an hour, so that gives 4 hours plus 800 seconds. The 800 seconds = 60*13 + 20 = 13 minutes, 20 seconds. This works out to 13 years, 8 months, 4 hours, 13 minutes, and 20 seconds. Though answers can vary depending on how many days you define to be in a year, and how many days in a month.

- Q: crane:300t lift 100t pad sizes:4.5x2 mtrs.ground bearing capacity required?

- This depends on the angle of the lift and the distance away from centre of the crane. With the lift at tipping range all 400t will be distributed along the outer half of the pad or on the extreme legs. Rule of thumb is all the load is placed under the one pad. so one pad is 9 sq metres and the load is 400 tonnes so the bearing capacity must exceeds 400/9 tonnes per square metre. 44.44444t/m^2

- Q: Hello, i am goin in on Dec 5 to write the millwright C of Q for the 3rd time. On the test there was a question that went something like this The crane is rated 40Ton, with a boom lenght of 40ft and at an angle of 70 deg. The jib is 8ft long on a 10 deg angle. What is the sefe working load. The numbers are not correct but that is how the question is phrased. Please help me with the formula. I cannot find it anywhere.

- Safe Working Load Formula

- Q: Secured to a concrete floor with 12 30mm bolts

- That can only be answered by analizing it. A crane as you are supposed to know has different loads and directions of impact due to the moving bridge, the trolley, and break loads. So what it can lift depend on the whole structure. Besides depends as much on the type of crane

- Q: The mobile crane has a weight of 116kip and center of gravity at G1; the boom has a weight of 29kip and center of gravity at G2. Determine the smallest angle of tilt θ of the boom, without causing the crane to overturn if the suspended load is W = 38kip . Neglect the thickness of the tracks at A and B. Determine the smallest angle of tilt θ of the boom, without causing the crane to overturn.

- Smallest Crane

- Q: I know you need to put current around the magnet (or certain type of metal) in order to attract but is it possible to use as pushing an object away. if there is please tell me how!

- To push an object away, you need equipment that is low to the ground when it applies the force. Bulldozers are designed to push objects. Electromagentic cranes are designed to deal with vertical forces, so they are used to lift and drop metal objects. They use electricity to flow through coils wrapped around a metal core to generate a strong magnetic field. Trying to use them to push things could cause a crane to tip over since they are not designed to deal with horizontal forces. Even if you could get the electromagnet wired to repel metal objects, when you bring the electromagnet near the object, it would repel away in an unwieldy manner because of friction and interference with the ground. And trying to direct a large electromagnet at the end of a long chain would be difficult.

- Q: why was the japanese crane hunted for its plumage in the 20th century?

- At okorder /

- Q: Are there any standard requirements? If so, please show me some reference materials. Thank you, 20It's urgent, online, etc.. Thank youWould you please not write down the specifications? The specific methods of operation, with what materials are written on, thank you, good, you can add points

- The main purpose is to prevent the main cable fixed tower crane tower crane cable weight lead cable pulled bad (insulation damage, core pulling) etc.,

- Q: I'm not sure how to set this problem up. Any help would be greatly appreciated. Thank you :)

- We start using by defining mechanical Power: = P=Work/time What is the work here? We lift the box a given distance. Work=mgh Since we know the power of the crane, we can simply plug in the values and solve for t: t=mgh/P This is only true if the crane has a constant power, which seems to be the case LeSmartOne

- Q: What do lattice boom and hydraulic boom in cranes mean?

- LATTICE BOOM: See first link. This is where the boom (the portion used to support the load) is made like a lattice ... i.e. interconnected trusses and girders. The cables for lifting the load are run from the base of the boom to the load over pulleys/gears located at the boom's tip. The boom itself is NOT adjustable in length or in angle. HYDRAULIC BOOM: See second link. This crane uses hydraulics to adjust either the length of the boom, or the angle at which the boom joints intersect. It looks more like a single beam construction, although its probably closer to a tube type design (hydraulics may be inside or outside the arm). The load is raised/lowered by cables operating at the end of the boom ... not necessarily tied back to the bottom of the boom.

Send your message to us

Tower Crane TC6014 60M Max Working Range

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords