Topkit Tower Crane Specification TC7034(QTZ315)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detail of Tower Crane

Feature: Tower Crane Condition: New Application:Building,Construction,Industrial

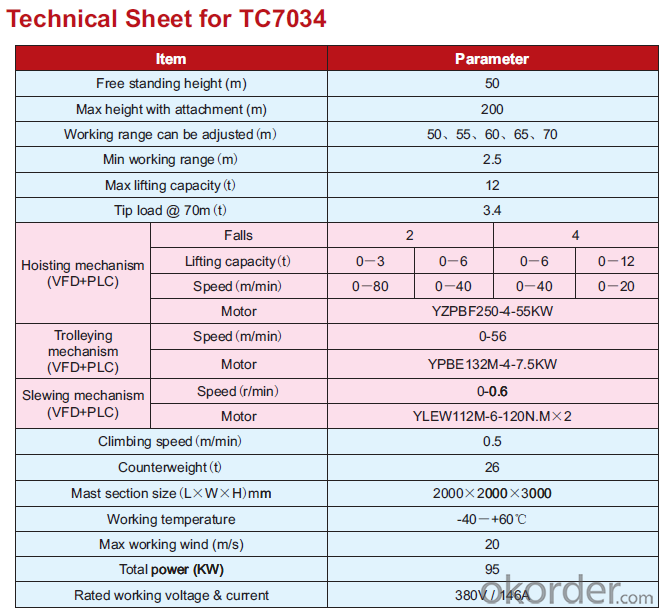

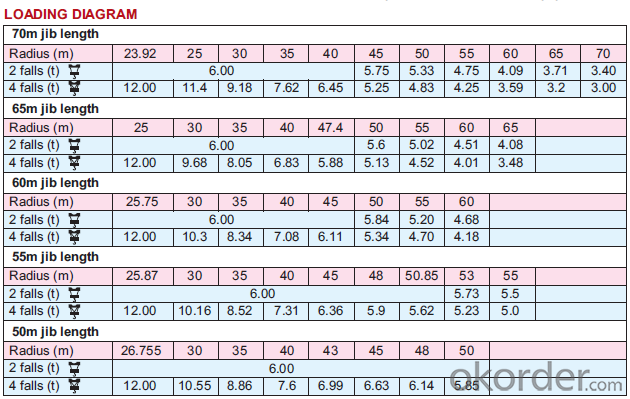

Rated Loading Capacity: 3.4-12T Rated Lifting Moment:315KN.M Max. Lifting Load: 12T

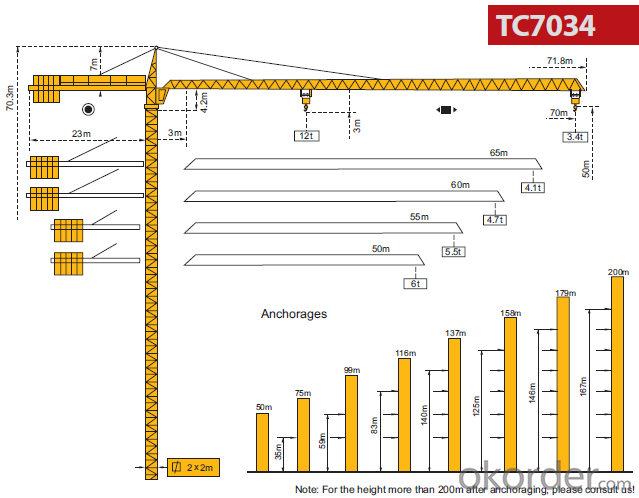

Max. Lifting Height: 200M Span: 2.5-70M Place of Origin: China (Mainland)

Brand Name: CMAX Model Number: TC7034(QTZ315) Certification: ISO,CE

Warranty: 1 Year Free standing height (M):50 Max. Working Range(M): 70

Tip Lifting Weight(T): 3.4 Working Range(M): 50,55,60,65,70 Climbing speed(M/MIN): 0.5

Counterweight(T): 26 Working Temperature(°C): -40-+60 Type: Topkit Tower Crane

Delivery Date:25-30 days Mast Section Size(L*W*H)MM:2000*2000*3000

Main Features of Tower Crane

1. TC7034(QTZ315) have competitive price and excellent quality, suitable for all kinds of construction project and can work under all kinds of work condition. With their working radius from 2.5 to 70m, TC7034(QTZ315) tower cranes are famous for their large operating ranges, varied working methods and wide uses.

2. This series of tower cranes has a horizontal jib frame, a jib-trolley radius-changing mechanism and a hydraulic self-raising mechanism.

3. It is original in design, reliable in operation and satisfactory in shape.

4. Equipped with all necessary safety devices, these cranes show a good speed-control capacity, satisfactory operating stability and high work efficiency.

5. Slewing mechanism and trolleying mechanism all take VFD+PLC technical control.

6. Outstanding in working efficiency, operating speed and stability. Reduce future maintenance cost.

7. With scientific layout and beautiful appearance.

8.They are widely applied for the construction of high-rise hotels, resident buildings, high-rise industrial buildings, large-span factory buildings and tower like buildings like tall chimneys.

9.After sales service will be offered which will get rid of all your worries in the purchase of our product

Specification of Tower Crane

Images of Tower Crane

FAQ about Tower Crane

Q: What kinds of tower crane are available now?

A: Four main categories: normal tower crane with cat head, internal climbing tower crane , top less tower crane and luffing tower crane.

Q: What kind of steel used for tower crane ?

A: Normally, as for the main force bearing steel structure, Q345B is adopted; as for the assistance force bearing steel structure Q235B is adopted. All of the raw material is outsourced from qualified steel factory in China.

Q: What about our tower crane warranty?

A: Usually there is one-year quality warranty including main electronic parts (not including consumable parts). There are consumable spare parts together with whole machine and normally they are enough for one year.

Q: What is 3 main mechanism of the tower crane ?

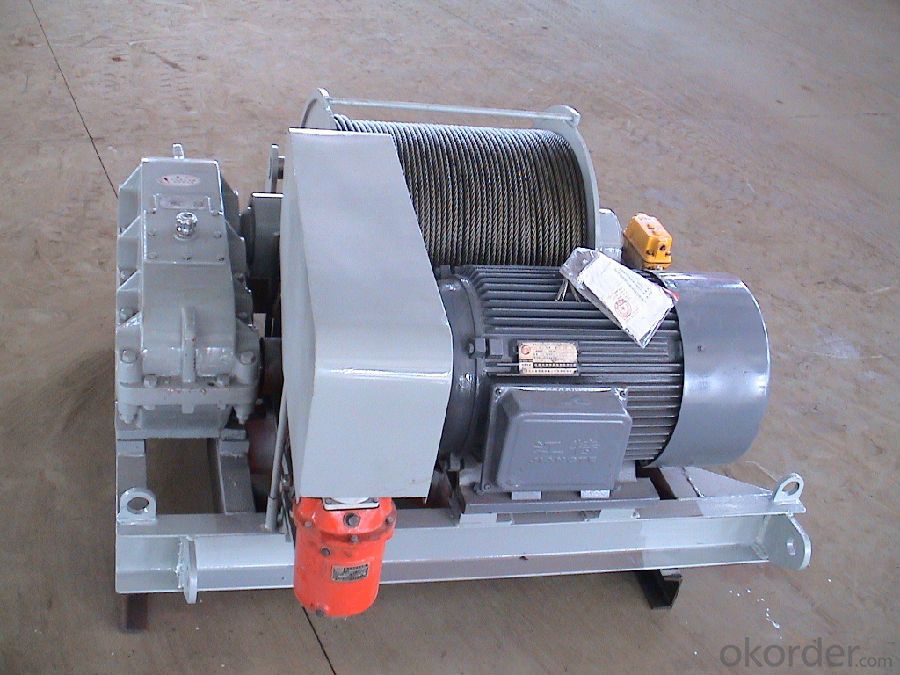

A: there are trolleying mechanism/ slewing mechanism/ hoisting mechanism.

Q: Can you equip with light on tower crane jib, monitor, remote control and anemometer?

A: Sure. All of these could be provided with extra cost upon the clients' requirements. But according to general practice, remote control is not suggested because most of the operator feedback operation in the cabin will provide a wide working view.

- Q: How to choose tower crane in engineering, such as arm length and lifting weight?

- 1, according to the general layout plan on the mechanical layout requirements to determine. The tower crane's arm length should be swept to the required area, otherwise the worker's formwork and materials can not be transported vertically. (tower crane is the main tool to solve vertical transportation, and auxiliary tools are derricks and double cage elevators)2. After a project has been obtained, it is important to design the layout plan of the field machinery at first. It determines the position of the tower crane and uses several tower cranes, etc. it also conforms to the requirements of economic rationality.3, we should take into account the location of the tower crane, but also take into account the length of the tower crane, but also to meet the requirements of the site construction schedule.

- Q: Im hearing this like every day theres more going down..why is it happening? A terrorist plot perhaps? I say we send some troops to stand guard and prevent another tragedy!

- These are dangerous peices of equipment, they endure high stress and are at times pushed to the physical limits. I have on occassion worked with and under them and always had a lot of respect and always felt safer when away from them. Construction cranes in particular are more dangerous because they are forever changing in height,position, amount and type of load. Cranes in permanent installations are ususlly carrying same or similar loads. Construction sites are hazardous due to many factors but just about everything on site gets handled by the crane at one time or another. Inspection,inspection, and re-inspection with concurrent correction/adjustment are the only preventative measure availble beside the assurance of competency of the operator. There are plenty of laws about them already but this is not to say new ones might be justified as new hazards become apparent. Most terrorists are too dumb or lazy to get involved with cranes--why bother when so many easy targets are out there !!!!!!!!

- Q: The truck has a Comprehensive Motor insurance cover. There is no exclusion in the policy in respect of tools of trade.

- read your insurance policy.

- Q: the question is :Two cranes can unload a ship together in 15 hours. The faster crane takes 16 hours less than the slower crane, if each were to unload the same ship alone. How long doesi t take for each crane to unload this ship? I done most of the math but i am stuck with this last part .15+- radical 1185/2

- No. of hours for the slower to unload alone—x: 1/x + 1/(x - 16) = 1/15 (x - 16 + x)/(x? - 16x) = 1/15 15(2x - 16) = x? - 16x 30x - 240 = x? - 16x x? - 46x = - 240 x? - 23x = - 240 + (- 23)? x? - 23x = - 240 + 529 (x - 23)? = 289 x - 23 = 17 x = 40 No. of hours for the faster to unload alone: = 40 - 16 = 24 Answer: slower crane, 40 hrs; faster crane, 24 hrs Check: = 15(1/40 + 1/24) = 15([3 + 5]/120) = 15(8/120) = 15(1/15) = 15/15 or 1

- Q: I've read significance and accordance online. But i can't find a source for defiance, I used epub bud for the other two books but this book isn't on the website. Is there anyway I can read defiance by Shelly Crane online for free?

- tuebl.ca/

- Q: In order to ensure the stability of tower cranes, generally along the height of the tower and building a number of meters attached

- Self lifting tower crane tower 45 meters high to prevail, such as height of over 45 meters, each increased to 10 meters (less than 5 meters, excluding) demolition costs increase 20%, off-site transportation costs increased by 10%.

- Q: A. Power LinesB. WaterC. FiresD. Overturns

- Dangerous to whom and exactly what does overturns mean? Operators are most likely to be killed when a tower crane breaks (is this an overturn?) because the operator is several hundred feet up in the air in the cab. Hitting power lines can be risky to the operator if dumb but staying in the cab is likely to be safe (stepping out may kill in touching ground) Overturning a ground based crane is going to hurt someone in the area much of the time.

- Q: I need to know exactly how much weight they can lift also how much do they weight?how long is thier life-time?in what temprature they can work?does mosture do any harm to them?for installation , do they need foundation?the exact height and width?

- You need to be more specific. The lifting capacities for container cranes varies significantly, as does any other crane. Some of the variation is based purely on load (horsepower) availability; some is based on speed (rpm) for lift/drop portions of the cycle. Cranes like these operate year-round, at ports all over the world. Some ports have average ambient temperatures in the range of 45 C, with highs up to 60 C. Others can be as low an average as 10 C, with a low peak as much as -50 C. Moisture will, over the long haul, harm them - they're metal constructs, and thus are prone to oxidation. Using corrosion-resistant materials and/or coatings will certainly prolong their usable lifespan. The crane drives (electric motors and power electronics) are also susceptible to moisture and other contaminants. All true dockside cranes require some sort of permanent foundation; it's usually part of the pier construction itself. However, there are portable cranes that operate without one. There is also more than one crane manufacturer out there - all will have their trade secrets that will make each look a little different than the rest. It will generally also reflect in their operation parameters, and in their expected life cycle.

- Q: What kind of bodies are tower cranes made of?

- First, the working mechanism of tower cranesThe working mechanism of tower crane is usually composed of lifting mechanism, luffing mechanism, slewing mechanism, hydraulic jacking mechanism and running mechanism.The hoisting mechanism to realize heavy vertical up and down movement; luffing mechanism and slewing mechanism to achieve weight moving in two horizontal directions; hydraulic lifting mechanism of standard section, increase or decrease, so as to increase or decrease the tower; range of weights can achieve walking mechanism in tower crane and force of arbitrary space motion.

- Q: What are the differences between the tower crane and the lift?

- Tower crane is a machine which transports construction materials within the construction site based on its radial range. Usually the radius of tower crane is around 50m to 60m. Capacity ranges from 3 to 6 tons Lift is only used for vertical transport of materials or people in certain building or construction site. Capacity ranges from 2 to 4 tons.

Send your message to us

Topkit Tower Crane Specification TC7034(QTZ315)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords