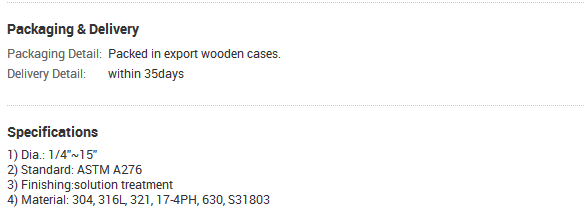

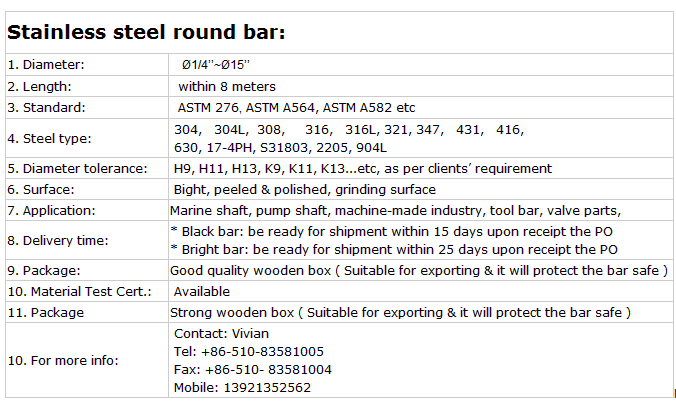

Top quality stainless steel bright round bar 316L 630 2205

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Are stainless steel pipes suitable for wastewater treatment plants?

- Indeed, wastewater treatment plants find stainless steel pipes to be quite suitable. The reason lies in the fact that stainless steel boasts remarkable resistance to corrosion, a quality of utmost importance in an environment where wastewater might house aggressive chemicals and substances. Not only can stainless steel pipes withstand the elevated temperatures and pressures commonly present in wastewater treatment plants, but they also prove to be a long-lasting and dependable option. Furthermore, the ease with which stainless steel pipes can be cleaned and maintained further diminishes the likelihood of contamination during the treatment process. Hence, the durability, corrosion resistance, and ease of maintenance that stainless steel pipes offer have made them a favored choice for wastewater treatment plants.

- Q: Can stainless steel pipes be used in food processing plants?

- Indeed, it is possible to utilize stainless steel pipes within food processing facilities. Stainless steel has gained popularity as a preferred piping material in the food sector due to its multitude of advantages. Firstly, the corrosion resistance of stainless steel is of paramount importance in an environment where pipes are consistently exposed to moisture and various chemicals. This ability to resist corrosion aids in preventing food contamination and upholds the integrity of the processing system. Furthermore, stainless steel pipes possess a smooth surface, facilitating ease of cleaning and maintenance of hygiene standards. The smooth surface inhibits the accumulation of bacteria and other contaminants, thereby reducing the risk of foodborne illnesses. Stainless steel is also non-reactive, meaning it does not release any harmful substances into the food products during the processing phase. This characteristic is particularly crucial when handling acidic or alkaline foods that may interact with other materials. Moreover, stainless steel is a robust and long-lasting material, capable of withstanding high temperatures and pressures. This durability renders it suitable for a wide range of food processing applications. In conclusion, stainless steel pipes are an exceptional choice for implementation in food processing plants due to their corrosion resistance, ease of cleaning, non-reactive nature, and durability. They play a significant role in ensuring food safety, maintaining high hygiene standards, and providing a reliable and enduring piping solution for the industry.

- Q: Can stainless steel pipes be used for aerospace applications?

- Yes, stainless steel pipes can be used for aerospace applications. Stainless steel is known for its high strength, corrosion resistance, and durability, making it suitable for various aerospace components and structures. Its ability to withstand high temperatures, pressures, and environmental conditions makes it an ideal material choice for aerospace applications.

- Q: Can stainless steel pipes be used for oil and gas transportation?

- Indeed, the utilization of stainless steel pipes for the transportation of oil and gas is plausible. Due to its exceptional resistance to corrosion and durability, stainless steel has become a favored material choice within the oil and gas industry for pipe construction. These pipes possess the capability to endure harsh circumstances, including high pressure, extreme temperatures, and corrosive surroundings, rendering them appropriate for the conveyance of oil and gas. Furthermore, the purity of the transported fluids is maintained by stainless steel pipes, as they exhibit no reactivity or contamination towards the substances being conveyed. As a result, stainless steel pipes are an unquestionably dependable and efficient option for oil and gas transportation.

- Q: What is the difference between 304F and 316F stainless steel pipes?

- The main difference between 304F and 316F stainless steel pipes lies in their chemical composition and corrosion resistance properties. 304F stainless steel contains a higher percentage of chromium (18-20%) and nickel (8-10.5%), which provides good corrosion resistance in mildly corrosive environments. On the other hand, 316F stainless steel has a higher percentage of chromium (16-18%), nickel (10-14%), and molybdenum (2-3%), making it more resistant to corrosion, particularly in chloride-rich environments. Therefore, 316F stainless steel pipes are generally preferred in more corrosive and marine applications.

- Q: Is galvanized steel pipe stainless steel pipe?

- Galvanized steel pipe is a kind of welded steel pipe, and its essence is hot-dip galvanized coating on the inner and outer surface of welded steel pipe. Hope to be of help to you.

- Q: Are stainless steel pipes suitable for hygienic applications?

- Indeed, hygienic applications can benefit greatly from the use of stainless steel pipes. Industries such as food processing, pharmaceuticals, and dairy heavily rely on stainless steel due to its ability to maintain cleanliness and prevent contamination. One key advantage of stainless steel is its exceptional resistance to corrosion. This is particularly significant in hygienic environments where bacteria and pathogens must be kept at bay. Stainless steel pipes demonstrate a remarkable resistance to rust and corrosion, even when exposed to various chemicals and cleaning agents commonly used in such settings. This resistance ensures the pipes' integrity and effectively prevents any contamination from occurring. Moreover, stainless steel boasts a smooth and non-porous surface, which greatly facilitates its cleaning and sanitization. This smoothness prevents the accumulation of dirt, bacteria, and other particles, thereby enabling the maintenance of a hygienic environment. Cleaning stainless steel pipes can be effortlessly accomplished using a range of methods, including steam, high-pressure water, or chemical cleaning agents. Furthermore, stainless steel is an extremely durable and long-lasting material. It can withstand high temperatures and pressures, making it suitable for an extensive array of hygienic applications. These pipes can be employed to transport fluids, gases, or other materials without compromising their hygienic properties. Additionally, stainless steel exhibits non-reactive properties, meaning it does not react with the substances it comes into contact with. This characteristic is of utmost importance in preventing any contamination or alteration of the transported substances. In conclusion, stainless steel pipes are highly appropriate for hygienic applications due to their exceptional resistance to corrosion, smooth surface, durability, and non-reactive properties. These pipes offer a dependable and hygienic solution for industries wherein cleanliness and prevention of contamination are paramount.

- Q: Can stainless steel pipes be used for oil refinery applications?

- Oil refinery applications can indeed use stainless steel pipes. Due to its exceptional resistance to corrosion, high durability, and strength, stainless steel is widely utilized in the oil and gas industry. Oil refineries face harsh and corrosive environments, including exposure to various chemicals, high temperatures, and pressure. Stainless steel pipes have the ability to withstand these conditions and provide long-lasting performance. Stainless steel pipes possess resistance to corrosion resulting from acidic and alkaline substances, which are commonly present in oil refinery operations. They also exhibit excellent resistance against pitting and crevice corrosion, making them ideal for handling crude oil, petroleum products, and other corrosive media. Moreover, stainless steel pipes can handle high temperatures without compromising their strength and integrity. This quality is crucial in oil refineries where heating and cooling processes are involved. Apart from corrosion resistance and high-temperature capabilities, stainless steel pipes also possess exceptional mechanical properties. They are robust, durable, and possess good weldability, making them suitable for the demanding conditions of oil refinery applications. In conclusion, stainless steel pipes are a reliable option for oil refinery applications due to their corrosion resistance, high-temperature capabilities, and mechanical properties. They ensure the safe and efficient transportation of oil and petroleum products, thereby contributing to the seamless operations of oil refineries.

- Q: What is the pressure rating of stainless steel pipes?

- The pressure rating of stainless steel pipes may vary based on various factors, including the grade of stainless steel, pipe wall thickness, and pipe diameter. Typically, stainless steel pipes have high pressure ratings due to the material's strength and corrosion resistance. However, consulting the relevant standards and specifications is necessary to determine the precise pressure rating for a specific stainless steel pipe. These standards (such as ASME B31.3 or ASTM A312) offer guidelines and calculations to establish the maximum allowable working pressure (MAWP) based on the mentioned factors. To ensure safety and prevent any potential failures or leaks, it is crucial to verify that the pressure rating of the stainless steel pipes is suitable for the intended application.

- Q: Can stainless steel pipes be galvanized?

- No, stainless steel pipes cannot be galvanized. Galvanizing is a process used to protect steel or iron from corrosion by coating it with a layer of zinc. Since stainless steel is already resistant to corrosion due to the presence of chromium, galvanizing is unnecessary and ineffective.

Send your message to us

Top quality stainless steel bright round bar 316L 630 2205

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords