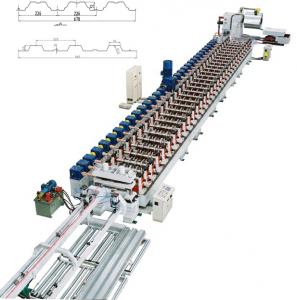

The anode plate forming equipment

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

1.technical process

uncoiler--leveling unit--forming machine--hydraulic cutting unit--collection table

2.main technical parameter

dimension:width 400mm-1000mm

materialthicknss:1.0-1.5mm

material:stainless steel,cold roll steel

production speed:5-12m/min

total power:about 35kw

area:about 30*3m

3.product description

annode plate roll forming machine can produce C480,Z385,ZT24 type anode plate by change the rollers.

- Q: What is the roll forming machine?

- The mold base elliptical motion device comprises a mold base, a slider, a slider block, a mold plate, a fixing plate, an elliptical long shaft adjusting rod and a mold base, wherein the mold base is connected with the slider through the lower part,

- Q: How is the molding machine installed?

- 3 check the reducer, shaking table of the shock absorber oil tank and the lubrication point is required to refuel, oil is appropriate;

- Q: How to maintain the molding machine?

- 5 After the end of the work every day, the various parts of the machine should be in the initial state and thoroughly clean the various parts of the machinery to prevent concrete in the mechanical condensation, but not water washing machine;

Send your message to us

The anode plate forming equipment

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords