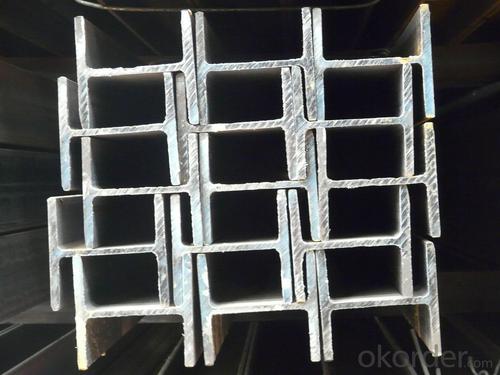

High quality H section

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Dimensions: | 41x21,41x41,41x62,41x72,41x83 | Grade: | Steel |

| Place of Origin: | Shanghai China (Mainland) | Brand Name: | BESCA | Model Number: | BS |

| Shape: | C Channel | Application: | Support | Perforated Or Not: | Is Perforated |

| Thickness: | 1.5-3mm | Finish: | Electro zinc plated ,Hot Dipped Galvanized,Electrolytic Polishing | Trade type: | Manufacture and Export |

| Certification: | CE ,SGS,ISO,NEMA,CCC | Export Range: | Cable Ladder,Cable Tray,Cable Trunking,,Wire Way,FRP | Length: | 2440/3000/5800/6000mm |

Packaging & Delivery

| Packaging Detail: | 1.standard package 2.as request |

| Delivery Detail: | 20 days after reciept of deposit |

Specifications

perforated c strut channel specification

1.Best price & No MOQ

2.Anti-corrosion & Fast heat dispersion

3.NEMA and CE etc.

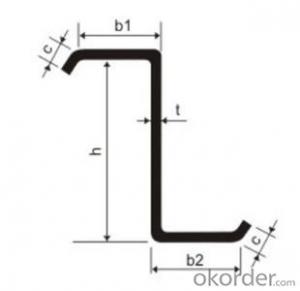

Strut Channel Detailed Specification:

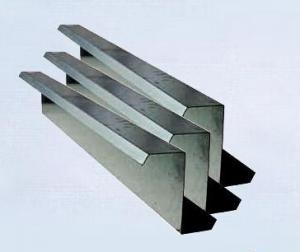

Strut Channel provides:

High quality & reasonable Price, no need welding and punching, can use repeatedly, wide usage range, flexible for installation.

♦ Standard thickness: 1.5mm, 2mm, 2.5mm,2.75mm, 3mm

♦ Standard length: 2440mm, 3000mm, 5800mm, 6000mm

♦ Standard size: 41*21, 41*25, 41*41,41*62,41*72,41*82

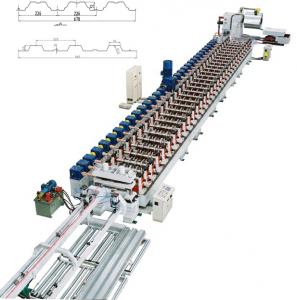

- Q: What is the roll forming machine?

- The elliptical rolling machine is composed of a rolling device, a rolling pan, a transmission and a brake device, a base, a spindle assembly, a die seat elliptical movement device, a rolling head seat, an electric motor and an electrical control system

- Q: How is the molding machine installed?

- Factory QTJ4-25 block forming machine have been in accordance with the relevant provisions of the factory have done the factory test, but due to long-distance transport and a long time to place and other reasons, the installation should be the following checks:

- Q: How to maintain the molding machine?

- 5 After the end of the work every day, the various parts of the machine should be in the initial state and thoroughly clean the various parts of the machinery to prevent concrete in the mechanical condensation, but not water washing machine;

Send your message to us

High quality H section

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches