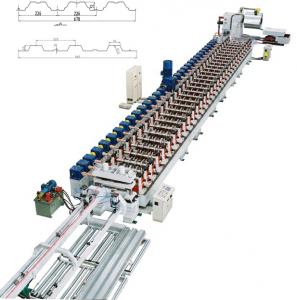

Auto Folding & Slitting Machines

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets Per Year set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General information of Auto Folding & Slitting Machines:

Ⅰ | Main Parameter | |

(1) | Model | CNBM - Auto Folding & Slitting Machine |

(2) | Effective Length | 8000mm |

(3) | Number of Pressure Head | 7 |

(4) | Machine Weight | About 5400Kg |

(5) | Pressing Force | 130 KN |

(6) | Folding Range | 0° - 125° |

(7) | Throat Depth | 800mm |

(8) | Bottom Bench Width | 27mm, including 12.7mm removable quadrat |

(9) | Top Bench Width | 28mm |

(10) | Hinge | Parallel links, ± 0.3mm tolerance |

(11) | Bench action Device | Hydraulic double-action oil cylinder |

(12) | Circulating Time | About 12 seconds (maximum folding) |

(13) | Hydraulic Power | 11KW |

(14) | Main Power | 11.5KW |

(15) | Size | 9395mm×1842mm×1375mm (L×W×H) |

Ⅱ | Slitting System Parameter | |

(1) | Model | Swivel knife |

(2) | Diameter | 100mm |

(3) | Material | W18 Cr4V |

(4) | Driven System | Hydraulic motor and chain-driven |

(5) | Shearing Speed | About 0.8m/s |

(6) | Shearing Distance | About 50mm away from top knife |

Ⅲ | Folding and Slitting Parameter | |

(1) | Maximum Folding Thickness | 1.5mmfor steel sheet (maximum yield strength ≤ 250Mpa); 2.0mm for soft aluminum sheet; 1.0mm for stainless steel sheet |

(2) | Maximum Folding Length | 8000mm |

(3) | Maximum Slitting Thickness | 1.5mmfor steel sheet (maximum yield strength ≤ 250Mpa); 2.0mm for soft aluminum sheet; 1.0mm for stainless steel sheet |

(4) | Minimum Folding Size | 10mm(sheet thickness <1.2mm); 20mm (sheet thickness ≥ 1.2mm) |

Reference Pictures of Auto Folding & Slitting Machines:

- Q: What is the roll forming machine?

- The mold base elliptical motion device comprises a mold base, a slider, a slider block, a mold plate, a fixing plate, an elliptical long shaft adjusting rod and a mold base, wherein the mold base is connected with the slider through the lower part,

- Q: How is the molding machine installed?

- 3 check the reducer, shaking table of the shock absorber oil tank and the lubrication point is required to refuel, oil is appropriate;

- Q: How to maintain the molding machine?

- 4 prohibits vibrator no-load operation;

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 1993 |

| Annual Output Value | US$ 5 Million - US$ 10 Million |

| Main Markets | 15.00% Mid East 20.00% Europe 25.00% North America 30.00% SoUth America 10.00% Others |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 4-10 People |

| Language Spoken: | English; Chinese; Russian |

| b) Factory Information | |

| Factory Size: | Above 10,000-30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Auto Folding & Slitting Machines

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets Per Year set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords