High Quality C Profile Cold Forming Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

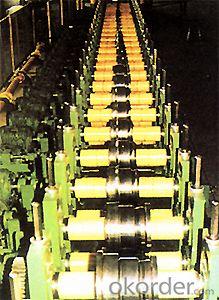

NAME OF GOODS:TFZ shaped steel cold roll forming line

Technique data

(1) Material of coil: carbon steel

(2)Suitable Coil Thickness: 1.0-3.2mm

(3) Feeding Width: approx 535mm

(4) Suitable coil I.D.: Φ508 mm

(5)Producing speed: 0- 40m/min

Working flow

Un-coiling–leveling–punching &cutting- Guiding—Guiding— roll forming—automatic run out table.

(1) Hydraulic Un-coiler

(2) Guiding Device

(3) Leveling Device

(4) Punching &cutting Device

(5)Roll-Forming M/C

(6)Move cutting Device

(7) automatic run out table.

(8) Hydraulic system 1 set

(9) PLC Control System

Equipment function and structure describe

(1) Hydraulic un-coiler:

Used for support and uncoils the coil, electric reducer drives uncoiling, tensioned by hydraulic pressure, with arm pressure, structure is reasonable, operated conveniently.

electro optical device controls coil position

Coil ID: φ508mm

Coil OD: φ1200mm

Max capacity: ≤3T

(2) Leveler

Releasing and feeding the head panel and leveling the panel, driven by the power of the roll forming machine. It has pinch and leveling rollers. The pinch roller can move up and down to adjust leveling space and inclination angle. It adopts 5 leveling rollers and 1 pair guiding rollers.

Suitable thickness: 1.0mm-3.2mm

Suitable Max. Width: 535mm

Material of roller :40Cr shaft of roller:¢70 power of motor: 4.4KW

(3) Punching &cutting Device

Adopt four column structure hydraulic drive, automatic measure length ,when reach the preset hole position ,it will auto-stop to punch then cut the sheet.

Suitable thickness: 1.0mm-3.2mm

Suitable Max. Width: 535mm

Material of punch die:Cr12 Material of cuter:Cr12 ,punching size is adjustable

(4) Feeding guider

The vertical center can be adjusted, adjustable hand wheel matched on one side to control, it is locked and located.

Adjustable guider, there are pressing rollers in front of the machine, each side has two unit guiding structure, can be adjusted separately.

(5) Forming machine

Adopts separated stander, machine base adopts welded structure, feeding and guiding devicegoes through distressing dealing; fine carbon steel roller shaft; with strengthener to make sure the products’ precision. Different sizes of one profile can be achieved through change spacers conveniently.

Main machine transmission mode: main electric reducer→distribution reducer →shaft joint → torii roller shaft

The roll forming craft adopts professional software design, can reach high roll forming precision. Roller adopts Cr12MoV, the hardness after quenching is HRC58-62, improve wearing resistance; shaft adopts well carbon steel and tempering and hardening process to make sure profile precision. Rollers are installed face the last leveling roller to make sure the profile’s precision.

Parameter of forming machine | ||

Forming station | 12 steps | |

Material of shaft | 45# | |

Diameter of shaft | φ80mm | |

Material of roller | Cr12MoV, HRC58-62 | Chrome polishing on surface |

Power of main motor | 30kw | ABB |

Gear box | Chinese brand | |

Bearing | LYC | |

Producing speed | 0-40m/min | |

NOTE: Different thickness profiles can be produced through adjust the distance of upper and down shaft, different size profiles can be achieved through adjust rollers and spacers.

(6) Moving Cutter

Function and structure:

With independent hydraulic system; servo-motor drive the cutting device to move

Cutting profile with no waste;

The products will fall directly on supporting rack after cut.

Parameter:

Molding cutting mould hardness is HRC58-62, material is Cr12,include 5 pairs of shears

Cutting tolerance ±2mm

(7) Automatic run out table

Function and structure : this section consists of galvanized supporting roller and shaped steel welded frame, products run out from side, pneumatic control .total length is 6 meters. The max width 500mm

(8) Control system:

The whole line adopts PLC control, human and machine screen. There are two operation types (Manual and automatic), the line just need one worker to operate in normally. On manual status, you can achieve single step action; it is convenient to repair; on automatic status, you can make the whole line run; the whole line is with emergency stop, in order to protect the human safety.

Outer control wire uses the quick plugs.

Operation display is English version.

Other low voltage electric units adopts Schneider brand.

(9) Roller material: bearing steel

(10) Main frame: 400H steel

(11) Medium plate thickness: 20mm

(12) Control system: PLC computer control with inverter

(13) Power supply: 380V, 3 Phase, 60Hz

- Q: What is the roll forming machine?

- The mold base elliptical motion device comprises a mold base, a slider, a slider block, a mold plate, a fixing plate, an elliptical long shaft adjusting rod and a mold base, wherein the mold base is connected with the slider through the lower part,

- Q: How is the molding machine installed?

- 3 check the reducer, shaking table of the shock absorber oil tank and the lubrication point is required to refuel, oil is appropriate;

- Q: How to maintain the molding machine?

- 2 check the vibration platform, mold box and slider, vibrator and indenter beam, feeding settings and the main frame and other parts of the connection bolt is loose;

Send your message to us

High Quality C Profile Cold Forming Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords