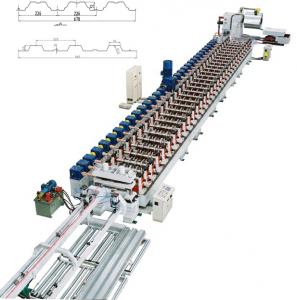

High-grade purlin rolling machinery and equipment

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The use of places

Edit

The prestressed concrete pillar molding machine is based on the modernization of the rural township building facilities and the needs of economic development, a new model based on the prestressed concrete pillarmolding machine on careful research, cement product a column machine,grape frame machine, machine, machine, cement pillars purlin columnmachine, mainly used for vegetable greenhouse column, grape frame columncolumn, orchards, livestock farms, such as column, farm planting flowers shed.Compared with the traditional handicraft industry, the machine work efficiency is increased by 10-15 times, and has the advantages of simple operation,convenient maintenance. This machine can design a variety of types and dimensions. [1]

2 safe use

Edit

Column machine purlin machine before use, to check whether reliable landconnection, device can tighten the bolts and nuts, around the chassis should add the smooth oil, can electrify launch machine test. The lower die columnmachine purlin machine use requires a mold and six on the standard scale asthe first device, the upper die and a lower die, a lower die is directly arranged on a six wheel operation platform, the upper die device on the sliding seat on the bottom plate and is properly positioned thickness, ensure that the upper and lower die, four peripheral gap uniformity, between the upper and lower dieinterval is equal to the desired thickness of the tile billet. And then as the upper mould, workbench transposition device of other five down moulds, allgood upper and lower die device driving pressure tile future talent. The first empty work closely, have no sensation, noise, oil window whether to oil, each component of motion can harmony, after all the normal ability to mold molddevice, device, it is necessary to cut off power supply, carefully move themotor belt or gear by hand, post purlin machine to make Taiwan transposition,and make slider up to the highest point, the best use of an object is supported on the operation table and slide the underside between, to prevent slippery anatural whereabouts, the formation of trouble. [2]

3 concepts

Edit

Purlin purlin machine [3], production of cement machinery.

Purlin roof length distribution along the horizontal component, located in the main rafter, supporting secondary rafters. Rural house used to provoke the rafters, roof rails made, is one of the main components of the house, also called on the slope roof truss, often used in roof or inclined beam, its add shopsheathing and tiles, as well the attachment member bar.

Because the durability and performance price ratio, cement purlin than wood and steel structure is applied more widely.

4 related specifications

Edit

The production of purlin products purlin machine when there is some basic design specifications: [4]

1, article mode can be designed into a single span simply supported beam and continuous components.

2, the span of more than 9 meters should be adopted when the lattice structure, and checked the stability of compression flange.

3, the lattice strips can be used planar Yan style, space Yan style or lowersupporting type purlin.

4, the solid web type purlin should adopt the lippedchannel, oblique curlingcold-formed thin-wall steel and straight edge curl Z shape cold-formed steel.

5 note

Edit

Matters purlin machine should pay attention to in the process of using a few:

The work of 1, purlin machine required when close the electrical cabinet, wiring boxes, console door or lid, lest dirt.

2, regular inspection and regular fastening pipe joint, to prevent loosening oil.

3, to ensure the accumulator charging pressure is sufficient and the capsule is normal, otherwise timely treatment.

4, must maintain the stable working voltage, the fluctuation value does not exceed the rated voltage of 5%-10%.

5, the operator of the hydraulic components are not allowed withoutdisassembly, when fault occurs, timely analysis of the causes of technical personnel, should be timely repair of equipment troubleshooting, not allowing the machine to work, to avoid causing accident.

The above four points is to produce the purlin purlin products should meet therequirements, what kind of specific needs, according to the building of the situation analysis.

6 the use of problem

Edit

Work purlin machine process, failure problems will inevitably arise various,before solving these problems, we must first find out the causes of problems,based on his experiences, in addition to several possible reasons a summary:

1, the pedestal is uneven;

2, spring pressure imbalance;

In 3, hopper inhomogeneous material;

4, the vibrator inversion;

5, unreasonable compounding, much less fine sand aggregate.

- Q: What is the roll forming machine?

- And said slider is provided in a slider seat with a dovetail groove structure in the lower part thereof to form a sliding mechanism; said slider block is connected with the main shaft by a taper sleeve method, The disk is fixed by bolts on a fixed plate with two elongated screw holes, one end of which is bolted to the slider and the other end abuts against the mold plate.

- Q: How is the molding machine installed?

- 1 check the machine in the transport process is damaged or deformation;

- Q: How to maintain the molding machine?

- 1 Check the host before driving is complete, than with loose and electrical loose, electrical grounding is good.

Send your message to us

High-grade purlin rolling machinery and equipment

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords