Advertisements plate, shed plate roll forming machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 8 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

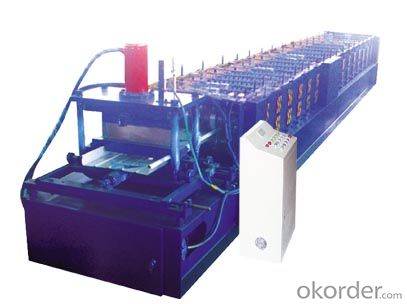

| Advertisements plate roll forming machine |

Advertisements plate roll forming machine is designed for the advertising industry to build a kind of less investment, quick effect, conveniently, widely used special equipment. This equipment products have beautiful appearance, high strength, quick installation, can be installed in a variety of color stitching, no apparent juncture, and multi-angle assembly can be vertical, horizontal, clearance can be adjusted to 0 to 6 cm, price is low wind resistance, etc.

Advertisements plate roll forming machine to produce colored steel gusset plate is mainly suitable for advertising signboard, building wall decoration, interior decoration, and all sorts of modelling of encapsulation, the super price becomes the best adornment material, this product does no other material after construction glue shedding and uneven surface, fade shortcomings, such as, is an upgraded version of print ads.

Corrugated panel roll forming machine

Main Teachnical Parameters

1.Material thickness: 0.2-1.0mm

2.Feeding width: 900mm

3.Effective width: 760mm

4.Forming speed: 12-16m/min

5.Diameter of the shaft: 70mm

6.Main power: 4KW

7.Forming steps: 16 steps

8.Material of shaft: 45#steel, quenched and tempered

9.Side board thickness: S18mm

10.Material of Rollers: Bearing steel

11.Driven style: by chain

12.Control system: Panasonic PLC

13.Hydraulic cutting part

i.Power: 3 KW

Material of cutter: Cr12, quenched

- Q: What steps are required during the installation of the cement tile machine?

- Host installation: the user in accordance with the size of the foundation map dug the foundation, according to the requirements of the drawings for the foot of the embedded hole or under the embedded iron with concrete pouring, for the installation of embedded holes into the anchor bolts (M24 × 360) and then Grouting, embedded iron can be a one-time cast into the installation and direct welding with the host, based on the plane must be level, the smaller the better the better.

- Q: Analysis on the Problems of Cement Shade Machine

- Peeling off all the foam, peel off part; follow the construction specifications, do grass-roots waterproof, before the construction of the grass-roots cracks to repair , To ensure that the grass-roots moisture content in line with construction requirements.

- Q: The processing method of the tile machine

- The billet is soft. Filter cloth part of the paste was dead, the next model of the local filter hole blocked, clean up. System without pressure, pump reversal: wiring error, adjust the steering. Insufficient power: motor failure or low voltage, power supply or repair motor. Oil pump temperature is too high: oil viscosity is too low, the pump is damaged, the cooling is insufficient or interrupted.

- Q: What are the advantages of cement tile machine?

- equipment investment, fast, high yield. More ordinary molding color tile molding unit: high technical content, fast, high yield (single class production increased by 80%), high product efficiency, good market prospects.

Send your message to us

Advertisements plate, shed plate roll forming machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 8 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords