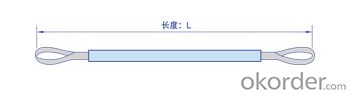

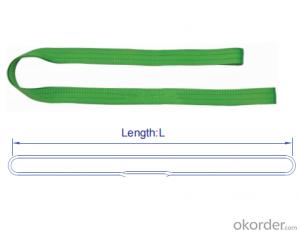

Textile Sling TYPE R02 (PROTECTION TYPE)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Textile Sling

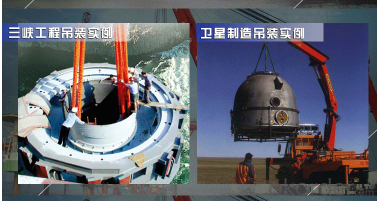

Textile sling factory is the largest base for lifting belts in the world with the production capacity over 20000t.We have thousands of manufacturing equipments, including Muller weaving machines from Switzerland,dyeing machines from Germany and automatic sewing machines form Japan,etc.

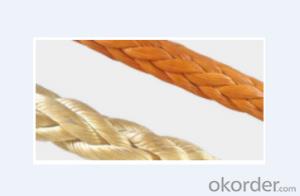

The main products are: webbing sling, round sling, ratchet strap, assembly sling, mooring rope and traction rope, according to different using environments, different materials would be used, such as polyester, polypropylene, nylon, Kevlar and HMPE (high molecular weight polyethylene material). We are able to manufacture special slings such as high-strength type, flame retardant type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant type, fluorescent type, optical inspection type and oil and water resistant type sling.

With characteristics like soft, light, no harm to the cargo, safety, long life and so on.

Product usage : Textile slings are widely used for lifting, pulling, bundling, fixed and other operations in machining, port handling, marine engineering, ship, electric power, transportation, aerospace and other fields.

Achievements in scientific research:

In 1997, we drafted out the industrial standard for textile slings together with Beijing Hoisting Machinery Institute: JB/T8521-1997, which makes historic progress for the Chinese textile sling industry.

In 2007, we revised JB/T8521.1-2007 “Textile Sling – Safety - Part 1: Common use webbing sling” and JB/T 8521.2-2007 “Textile Sling - Safety - Part 2: Common use round sling”.

In 2009, we edited GB/T 23914.2-2009 “Road vehicle mounted fixtures – Safety – part 2: Synthetic ratchet strap assemblies”, participated in writing TB/T 3123.11-2009 “Rescue devices for railway accidents - part 11: high-performance textile sling”.

In 2014, we participated in writing GB/T 30667-2014 “Polyester and polyolefin dual Fiber rope” and GB/T 30668-2014 “8 strands, 12 strands and multiflament braided Ultra high molecular weight polyethylene fiber rope”.

- Q: What tools are slings in lifting operations? What is the function of the slings?

- Sling made forms are more commonly used in engineering with inserting end ring and inserted nonpolar (Universal) slings in hoisting work are the steel wire rope is connected with a hook, shackle, sling made of various styles, for lifting, or binding.

- Q: What's the sling for a movie?

- Now the movie also used the wire, but the rope is made by thin steel wire, so as not to betray. WIA, commonly known as wire.

- Q: Ceiling installation does not allow the use of air nails?

- (1) construction materials: common materials are as follows.Wood (different specifications of water, wood, water board), aluminum alloy (plate, profile), steel (steel, flat steel, steel plate), mainly as supporting components.Plastic, plexiglass plate, glass partition plate, outer decorative veneer and heat dissipating plate, copper plate and electrochemical aluminium plate as decorative component.Other accessories such as screws, nails, rivets, finished lamps, adhesives and so on.(2) construction tools: pliers, screwdrivers, hammers, saws, electric hammer, hand according to the curve, a ruler, paint etc..

- Q: What are the precautions for rigging in hoisting works?

- The load weight shall not exceed the limit load of sling, sling should be used before the use of visual inspection, and according to the spreader lifting load check the working load limit, meet the requirements before use.

- Q: How do you tie the wire rope?

- Manganese phosphating belongs to wear, corrosion, phosphating, automobile transmission, steel gear is through the manganese phosphating treatment, can ensure that the car gear for more than ten years without damage. Phosphating coating of steel wire rope China patent technology production, give priority to the use of manganese or zinc manganese phosphating, and smooth steel wire rope production process comparison, just add the last bonderizing process, steel wire for rope wear resistance and corrosion resistance is greatly improved, the use of direct phosphating steel wire twisting steel wire rope. The fatigue test data show that the fatigue life of the phosphating coating of steel wire rope is about 3-4 times the same structure of domestic smooth steel wire rope, wire rope surface is 2-3 times of imports, (laboratory comparable conditions) with the research on the wear resistance of phosphating, and greatly enhance the possibility, is currently the most advanced technology in the world of steel wire rope field. Manganese phosphating is bonderizing, can solve the problem of wire rope wear during use, smooth wire rope being eliminated, because the phosphating coating steel wire rope in short supply, the more sought after, need to ask a few companies.

- Q: What are the selection principles for lifting cranes?

- Selection should take into account the performance of the crane (ie operation capacity), ease of use, hoisting efficiency, hoisting capacity and duration requirements.

- Q: Slings and rigging manufacturers, which cost-effective?

- Wire rope rigging, manganese phosphating coating steel wire rope is a new technology appearing in recent years. Wire rope has a long service life. Buy wire rope made of phosphating coating steel wire,

- Q: Is the sling the same thing as the rigging?

- This is not strictly divided, if not to say that the rigging refers to those parts of the spreader is rigging, such as rings, ring buckle, hook, shackle. The sling is a wire rope, lifting chain, lifting belt, these rigging consisting of a complete set for lifting tools, that is, sling. In practice, the two are inseparable. So they are generally called rigging companies. Hope to help you, which is the media, and have the opportunity, please welcome to interview our company.

- Q: What is the safety factor of the wire rope as a motor lifting equipment, slings and slings?

- 1 phosphating coating steel wire rope (patent products), steel phosphating manganese or zinc manganese by wire surface is very wear-resisting, effectively inhibit the occurrence of fretting wear, is a substitute for plain steel wire rope upgrade, service life far beyond the structure of smooth steel wire rope, wire rope including imported from developed countries such as Germany and Japan (currently the rope is about three times of phosphating, smooth rope after may also be able to improve the phosphating film 3-60 g / M 2, wire drawing no longer after phosphating processing, direct twisting wire rope), has been in China copycat wire rope technology innovation. The innovative technology is suitable for almost all kinds of high-quality carbon steel wire rope varieties, such as elevators, steel ropes, important use steel wire rope and so on.

- Q: Does the pressing rope have any influence on the tension value of the wire rope?

- The use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, manganese phosphating coating can greatly improve the wear resistance and corrosion resistance of the steel wire surface, the fatigue life of the phosphating coating steel wire rope is 3-4 times of smooth wire rope, up to 5 times, with the research on the wear resistance of the phosphating liquid, as well as to further improve the possibility.

Send your message to us

Textile Sling TYPE R02 (PROTECTION TYPE)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches