Tencate Miragrid High Strength Warp-Knitting Polyester Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Geogrid:

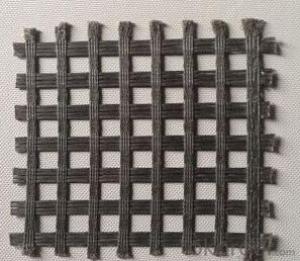

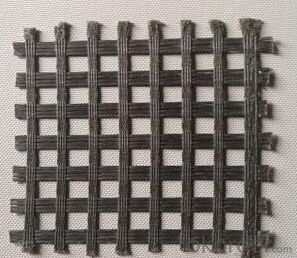

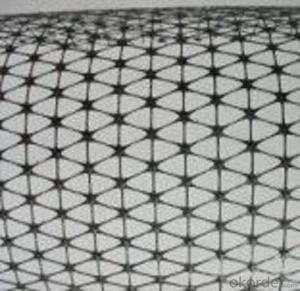

Warp-knitting Polyester Geogrid adopts industrial high strength, high modulus and low shrinkage twisting polyester fiber as raw material. With warp-knitted directional structure, there is no bend statement among warp and weft yarns of the fabric. The cross points of the geogrid are bundled and banded together by high-strength polyester fiber. So they form solid binding points. After coating with high-quality oil or water-soluble PVC, its physical and chemical property is greatly optimized.ams and dikes, and mountain slope 2) Can prevent land soil from water and rain erosion before grass covering grows 3) Can bear sourcing of high water space and high-speed water after grass covering grows 4) It can reduce cost of construction by width margin and the cost is only 1/7 concrete,1/8 stone 5) It adopts macromolecule material and anti-UV rays stability, and its chemical character is very stable, and there is no pollution to environment 6) Easy construction after surface of land is smooth 7) A kind of three dimensional structure new-type geosynthetical materials suitable for protecting water and land soil 8) Can effectively prevent water and land soil from flowing away, increase green land and improve living environment Operation: 1) Can use bamboo pole or wood stick pass the whole roll net mat during construction, then pull net mat along slope, use wooden nail or plastic nail to fix four circle of net mat, distance between nails is 750px, one square meter has 10 nails 2) Length of nail from land surface is usually 375px, add nails on loose land, length of nail on up slope is longer than on down slope when construction on high slope 3) Pay attention to keep netting mat smoothl

Applications of Geogrid:

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

Property of Geogrid:

1.) Improve roadbed bearing capacity,enlarge road lifetime.

2.) Prevent road collapse and crack

3.) Prevent soil and water loss in slope

4.) Could replace steel-plastic geogrid in coal mine.

FAQ:

1. How to order your geogrid ?

a). Tensile strength in warp & weft direction

b). Grid size

c). Width and length

d). Quantity

2. Payment term .

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

Geogrid Show:

- Q: How are geogrids connected to the surrounding soil?

- Geogrids are connected to the surrounding soil through a process called interlocking. The geogrids have openings or apertures that allow the soil particles to pass through. As the soil is compacted and fills these apertures, it creates a mechanical bond between the geogrid and the soil. This connection enhances the stability and load-bearing capacity of the soil, preventing lateral movement and reinforcing the overall structure.

- Q: How much is the tensile strength of geogrid???????

- Whole plastic stretch type: two-way products: 15KN--50KN one-way products: 50KN---300KN

- Q: What is the difference between a woven and a non-woven geogrid?

- A woven geogrid is made by weaving polyester or polypropylene yarns together, creating a strong and stable grid structure. On the other hand, a non-woven geogrid is made by bonding polyester or polypropylene fibers together, forming a random network of filaments. This results in different characteristics and performance. Woven geogrids typically have higher tensile strength and are more rigid, making them suitable for applications requiring load distribution and soil reinforcement. Non-woven geogrids, while generally having lower tensile strength, offer excellent filtration and separation capabilities, making them ideal for erosion control, drainage, and subgrade stabilization.

- Q: Can geogrids be used for reinforcement in embankments and dams?

- Yes, geogrids can be used for reinforcement in embankments and dams. Geogrids are high-strength synthetic materials that are commonly used in civil engineering and construction projects to increase the stability and strength of soil structures. By incorporating geogrids into embankments and dams, they can effectively reinforce the soil, reduce settlement, and improve overall performance and durability of these structures.

- Q: What is the difference between a uniaxial and a biaxial geogrid?

- A uniaxial geogrid is designed to provide strength and stability in one direction, typically in the longitudinal axis. It is used to reinforce soil or other materials in applications such as road construction, retaining walls, and embankments. On the other hand, a biaxial geogrid is designed to provide strength and stability in both the longitudinal and transverse directions. It offers enhanced reinforcement capabilities and is commonly used in applications where multidirectional support is required, such as steep slopes, ground stabilization, and pavement systems.

- Q: Are geogrids suitable for use in reinforced soil slopes?

- Yes, geogrids are suitable for use in reinforced soil slopes. Geogrids provide stability and reinforcement to the soil, preventing erosion and slope failure. They enhance the strength and load-bearing capacity of the soil, making them an effective solution for reinforced soil slopes.

- Q: What is the number of tensile elements of Geotextiles

- The tensile unit number of geotextiles: the strength of the geotextile under the action of a certain width of 1 meters. KN/m

- Q: Can geogrids be used in reinforcement of underground pipelines?

- Yes, geogrids can be used in the reinforcement of underground pipelines. Geogrids are a type of geosynthetic material that provide additional support and stability to the surrounding soil, preventing the pipeline from experiencing excessive deformation or damage. They are commonly used in pipeline installation and rehabilitation projects to increase the overall strength and load-bearing capacity of the soil, ensuring the long-term stability and functionality of the underground pipelines.

- Q: Engineering effect of steel plastic geogrid

- Steel plastic geogrid:When the geogrid is used in the soft ground treatment, the location and the number of the geogrid should be determined according to the geological condition.When the filling height is greater than 4m, the geogrid to meet the minimum requirements of industry standards, the vertical and horizontal limit tension should not be less than 20kN/mWhen the filling height is between 3-4m, the vertical and horizontal tensile force of geogrid is not less than 40kN/mWhen the filling height is less than 3m, the geogrid vertical ultimate tension is not less than 50 kN/m, the elongation is less than 4%, the proposed use of GSZ60-60 type geogrid when the geogrid embankment excavation combination should be used when the bidirectional geogrid is not less than 40kN/m, should adopt the GSZ60-60 type of GeogridAs for the old road widening old road junction, referring to the method of reconstruction and extension of the use of Grid: where the fill height is larger than 3 meters away from the roadbed, roadbed cap at 20 cm of paving plastic composite grille, with vertical (vertical line direction) limit tension is greater than or equal to 60kN/m, the transverse (parallel line direction) ultimate tension greater than or equal to the plastic composite geogrid 20kN/m, elongation is less than or equal to 4%.

- Q: See details of the application of design code for railway embankment geosynthetics TB10018-2006

- The vertical and horizontal strength fracture elongation is basically on the other side of the 2 point and sometimes the strength of the joint is required!

Send your message to us

Tencate Miragrid High Strength Warp-Knitting Polyester Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords