Tencate Mirafi Geogrids Plastic Grass Paving Grid / Plastic Parking Grass Grid / Parking Grass Grid Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

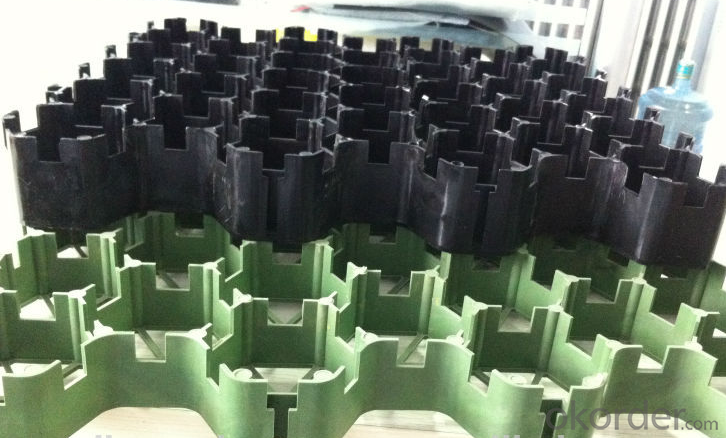

| Type: | Geogrids,Geomembranes | Place of Origin: | Shandong China (Mainland) | Brand Name: | Cmax |

| Model Number: | 001 | material: | HDPE | color: | green/black |

| certification: | CE /ISO9001 |

Packaging & Delivery

| Packaging Detail: | regular package or at requested |

| Delivery Detail: | within 7 days afetr advanced pament is received |

Specifications

Plastic grass grid:

1). completely greening

2) save investment

3) smooth surface

4) high strength

Plastic grass grid:

Plastic grass grid specifications:

make grass lawn and carprk two-in -one

HDPE materail, eco-friendly

proof pressure, wear- resisting, shock resistance,

Plastic grass grid Types:

hexagonal grass paver and circular grass paver

Height: 3.8cm, 5cm, 7cm

APPLICATIONS

Parking Lots (Grass or Gravel) & Overflow Parking

Overflow grass car & bus parking lots

Grass parking areas

Fire Truck Access routes / Fire Lanes

Helipads / Helicopter landing pads

Grassed light aircraft / airplane transport areas / taxiways

Handicap access routes

Golf cart paths

Emergency access roads

Residential access and parking spaces

Grass Driveway and grass shoulders

Polymer Density | High Density Polyethylene with density of 0.935 - 0.965 g/cm3 ASTM D 1505 |

Environmental Stress Crack Resistance | > 4000 hours ASTM D 1693 |

Carbon Black Content | Carbon black content 1.5% - 2.0% ASTM D 1603 |

Sheet Thickness | Smooth:1.1mm,1.2mm,textured:1.5mm ,1.7mm ASTM D 5199 |

Cell Details | welding distance:330-1000mm |

Cell Depth | 50-250mm |

Seam Peel Strength | As per US Army Corps of Engineer's Report GL-86-19 Appendix A |

Seam Hang Strength | A 100mm wide seam sample supports a 72.5 kg load for a minimum of 30 days in an ambient room temperature environment. |

Certification | CE ,ISO |

Classification | 1. smooth surface without hole 2. smooth surface with hole 3. textured surface with hole 4. textured surface without hole |

Plastic grass grid Characteristics:

1). completely greening

2) save investment

3) smooth surface

4) high strength, long service life

- Q: What are the long-term performance monitoring requirements for geogrids?

- The long-term performance monitoring requirements for geogrids include regular inspections, assessment of durability and strength retention, measurement of creep and relaxation behavior, evaluation of long-term deformation and stability, and monitoring of the geogrid-soil interaction. Additionally, it is vital to monitor any potential degradation from environmental factors such as UV exposure, chemical exposure, and biological activity to ensure the geogrid's effectiveness over time.

- Q: Longitudinal and transverse tensile strength more than 60kn/m which has several geogrid

- Glass fiber, polyester, plastic steel, PP, single and double, have 60 specifications.

- Q: What is the difference between a woven and a non-woven geogrid?

- A woven geogrid is made by weaving polyester or polypropylene yarns together, creating a strong and stable grid structure. On the other hand, a non-woven geogrid is made by bonding polyester or polypropylene fibers together, forming a random network of filaments. This results in different characteristics and performance. Woven geogrids typically have higher tensile strength and are more rigid, making them suitable for applications requiring load distribution and soil reinforcement. Non-woven geogrids, while generally having lower tensile strength, offer excellent filtration and separation capabilities, making them ideal for erosion control, drainage, and subgrade stabilization.

- Q: Are geogrids suitable for use in soil reinforcement for pipeline river crossings?

- Yes, geogrids are suitable for use in soil reinforcement for pipeline river crossings. Geogrids offer excellent soil stabilization and reinforcement properties, providing enhanced tensile strength and load-bearing capacity. They are particularly effective in areas with challenging soil conditions or high water flow rates. Geogrids can effectively distribute the loads from the pipeline, prevent soil erosion, and ensure long-term stability, making them a reliable choice for reinforcing soil in pipeline river crossings.

- Q: How to effectively control the quality of Geogrid in the process of construction

- 1 raw material quality in accordance with the required frequency and standard sampling, strengthening the construction of protection against pollution and destruction.

- Q: How do geogrids reinforce slopes?

- Geogrids reinforce slopes by providing tensile strength and stability to the soil, preventing erosion and retaining the soil in place. They act as a reinforcement layer, distributing the applied loads and reducing the potential for slope failure.

- Q: Water conservancy projects, the construction of the geogrid used in the quota which is not, how should the set of fixed price calculation of geogrid?

- Because the quota has been included in the lap

- Q: How do geogrids help in preventing differential settlement?

- Geogrids help in preventing differential settlement by providing reinforcement and stability to the soil layers. They distribute the load evenly across the foundation, reducing the differential settlement potential. Additionally, geogrids improve the soil's bearing capacity and increase its shear resistance, minimizing differential settlement risks.

- Q: What is the difference between uniaxial and biaxial geogrids?

- Uniaxial geogrids have strength and stiffness in one primary direction, typically in the machine direction. This means they provide reinforcement in one direction only. On the other hand, biaxial geogrids have strength and stiffness in both the machine direction and cross-machine direction, providing reinforcement in two perpendicular directions.

- Q: What is the quota of two-way steel plastic composite geogrid

- The algorithm is similar to that of the bottom of the plate, not by the area of the grid, but by calculating the length of the theoretical weight.

Send your message to us

Tencate Mirafi Geogrids Plastic Grass Paving Grid / Plastic Parking Grass Grid / Parking Grass Grid Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords