AISI420 G100 6mm Shot Magnetic Stainless Steel Balls

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM

Technique:

Cold Drawn

Shape:

Round

Surface Treatment:

Dry

Steel Grade:

420

Thickness:

0.045-2.8mm

Length:

0.045-2.8mm

Net Weight:

20kg/bag

Packaging:

Standard Export Packing

Product Description

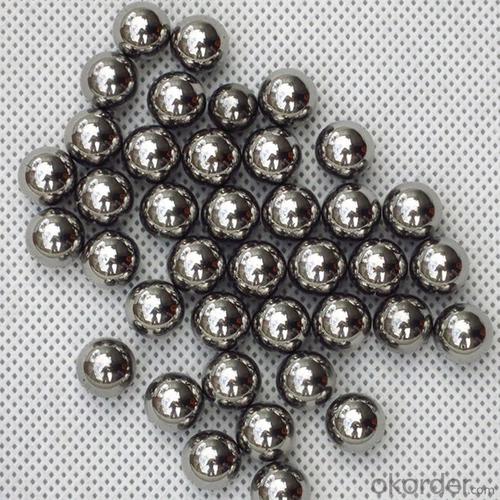

AISI420 G100 6mm Shot Magnetic Stainless Steel Balls

Products Picture

| Product | AISI420 G100 6mm Shot Magnetic Stainless Steel Balls |

| Material | stainless steel |

| Pericision | G100 |

| Hardness | HRC25-39 |

| Surface | zero defect , bright |

| Checking | 100% sorted |

| Sales mode | wholesale or retail |

| Sample | by free |

| Safe | ROHS |

| Package | four small boxes within a carton of20kg |

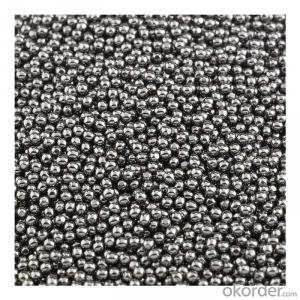

Expect the stainless steel ball , we have other steel balls . carbon steel ball , chrome steel ball .

In our company . The chrome steel ball have used in bearing , screw , grinding . The carbon steel ball have used in bicycle bearing ,slide. The stainless steel ball have used nail polish , grinding chocolate.

WHAT UNIQURE FEATURE DO I HAVE?

Products Picture

our company have the strict process :Raw material--Wire drawing--Cold heading--Flashing--Heat treatment--Grinding--Lapping1--Lapping2--Lapping3--Washing--Checking--Packing

High efficiency / High efficiency inspection

Our production capacity is 160 tons per month. we have the high quality testing instruments

for example : roundness measuring equipment , photometric sorter, metallographic structure detector, vibroscope,salt spray tester.

Green product

Our company product are all passed the ISO and SGS certification . They are all safe.

- Q: What are the different types of steel wire products?

- There are several different types of steel wire products, including steel wire ropes, steel wire mesh, steel wire cables, steel wire springs, and steel wire fencing.

- Q: What are the common types of steel products used in the marine industry?

- Common types of steel products used in the marine industry include shipbuilding plates, marine grade stainless steel, naval steel, and marine structural sections such as beams, angles, and channels.

- Q: What are the applications of alloy steel in the aerospace industry?

- Alloy steel finds various applications in the aerospace industry due to its exceptional properties. It is commonly used in the construction of aircraft parts such as landing gears, turbine engines, and structural components. Alloy steel offers excellent strength, high fatigue resistance, and good corrosion resistance, which are crucial for ensuring the safety and performance of aircraft. Additionally, its ability to withstand high temperatures and maintain structural integrity under extreme conditions makes it an ideal material for aerospace applications.

- Q: How is steel used in the manufacturing of consumer goods?

- Steel is used in the manufacturing of consumer goods in various ways, such as in the production of appliances, automobiles, furniture, and packaging materials. It is valued for its strength, durability, and versatility, allowing manufacturers to create sturdy and long-lasting products. Whether it's the frame of a car, the casing of a refrigerator, or the structure of a piece of furniture, steel plays a crucial role in ensuring the quality and reliability of consumer goods.

- Q: How is steel rebar used in concrete construction?

- Steel rebar, also known as reinforcing bar, is used in concrete construction to provide additional strength and stability to the concrete structures. It is placed within the concrete forms prior to pouring the concrete and acts as a reinforcement by absorbing tension forces and preventing cracks and failures. The rebar is strategically positioned to distribute the load evenly and enhance the overall structural integrity of the concrete.

- Q: How are steel plates heat-treated for improved strength?

- Steel plates are heat-treated for improved strength by subjecting them to a specific heating and cooling process known as quenching and tempering. This involves heating the steel plate to a high temperature and then rapidly cooling it to harden the material. Afterward, the plate is reheated to a lower temperature to temper it, which helps to reduce brittleness and improve its toughness and overall strength.

- Q: How is steel used in the production of process equipment for chemical plants?

- Steel is commonly used in the production of process equipment for chemical plants due to its strength, durability, and resistance to corrosion. It is used to construct various components such as tanks, pipes, valves, and reactors, which are crucial for storing and transporting chemicals throughout the plant. Additionally, steel's high melting point makes it suitable for handling high temperatures and pressures that are often encountered in chemical processes.

- Q: How do steel products contribute to the agriculture and farming sector?

- Steel products contribute to the agriculture and farming sector in several ways. Firstly, steel is used in the manufacturing of machinery and equipment essential for agricultural activities, such as tractors, combines, plows, and irrigation systems. These machines help increase efficiency, reduce labor, and improve productivity on farms. Additionally, steel structures, such as barns, silos, and storage facilities, provide durable and secure spaces for storing crops, livestock, and equipment. Steel is known for its strength, durability, and resistance to weather conditions, making it ideal for protecting agricultural resources. Furthermore, steel is used in the construction of infrastructure such as bridges and roads, which play a crucial role in connecting farms to markets and facilitating the transportation of goods. This infrastructure ensures that agricultural products can reach consumers in a timely and efficient manner. Overall, steel products contribute significantly to the agriculture and farming sector by enhancing productivity, providing storage solutions, and supporting the necessary infrastructure for the smooth functioning of the industry.

- Q: How is steel pipe welded for structural applications?

- Steel pipe is commonly welded for structural applications using various welding techniques such as electric resistance welding (ERW), submerged arc welding (SAW), or gas metal arc welding (GMAW). These methods involve applying heat and pressure to join two or more sections of steel pipe together, ensuring a strong and durable bond.

- Q: What are the different types of steel products used in the manufacturing of packaging materials?

- There are several types of steel products used in the manufacturing of packaging materials, including tinplate, tin-free steel, and stainless steel. Tinplate, made by coating thin steel sheets with a layer of tin, is commonly used for food and beverage cans. Tin-free steel, on the other hand, is similar to tinplate but lacks the tin coating, making it suitable for non-food packaging applications. Lastly, stainless steel, known for its corrosion resistance and durability, is often used for packaging materials that require high strength and hygiene standards, such as medical supplies or industrial products.

Send your message to us

AISI420 G100 6mm Shot Magnetic Stainless Steel Balls

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords