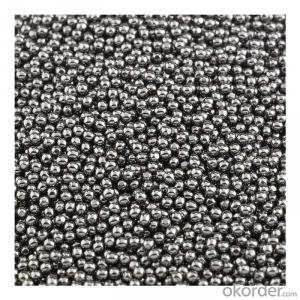

AISI420 Steel Shot 8mm G100 Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

THE DETAIL OF STAINLESS STEEL BALL| Product | Stainless steel ball |

| Material | stainless steel |

| Brand | SAIGE |

| Percision | G100 |

| Hardness | HRC>52 |

| Surface | zero defect, bright |

| Checking | 100% sorted |

| Sales mode | wholesale or retail |

| Sample | by free |

| Package | four small boxes within a carton of 20kg |

| Certification | ISO9100;2008SGS |

Products Picture

AISI 420 have good hardness and fair-to-good corrosion resistance and strength, it is generally used for all applications requiring resistance to corrosion such as bearings, valves, writting instruments, food environment, fresh water, many petroleum products and mild acid environments. AISI 420 is also magnetic.

AISI 420 stainless steel balls in our factory:

Minimum diameter :1.2mm

Best precision :G10

Hardness :HRc>52

SAFE PACKAGE

Step 1: Weighing stainless steel balls. Usually the weight is about 10kg.

Step 2: Sealed plastic bags

Step 3: Put sealed plastic bags into small boxes.

Step 4: Each box has the label, including material, Lot No. Size, quantity, grade, date and so on

Step 5: Each box directly put into mooden case.

High precision stainless steel balls usually is oil package. Normal precision stainless steel balls usually is dry package.

We also can pack them according to customers' request.

STEEL BALLS APPLICATION

Expect the stainless steel ball , we have other stainless steel ball . chrome steel ball , carbon steel ball .

They are all passed the ISO and SGS certification , They are all safe.

- Q: How is steel used in the manufacturing of oil and gas pipelines?

- Steel is commonly used in the manufacturing of oil and gas pipelines due to its exceptional strength, durability, and resistance to corrosion. It is used to construct the main body of the pipeline, providing a reliable and safe transportation system for oil and gas resources. Additionally, steel can withstand high pressure and extreme temperatures, making it suitable for the demanding conditions often encountered in the oil and gas industry.

- Q: What are the common uses of steel products in construction?

- Steel products are commonly used in construction for a variety of purposes such as structural framing, reinforcement of concrete, roofing, cladding, and fabrication of beams, columns, and trusses. Additionally, steel is used in the construction of bridges, highways, and other infrastructure projects due to its strength, durability, and ability to withstand heavy loads and harsh environmental conditions.

- Q: What are the common uses of steel in the defense industry?

- Steel is commonly used in the defense industry for a variety of purposes, including the manufacturing of military vehicles, armor, weapons, ammunition, and structures such as bunkers and fortifications. Its strength, durability, and ability to withstand extreme conditions make steel an essential material for ensuring the safety and effectiveness of defense equipment and infrastructure.

- Q: What are the applications of steel in the defense industry?

- Steel is widely used in the defense industry for a variety of applications. It is utilized in the construction of military vehicles, such as tanks and armored personnel carriers, providing them with the necessary strength and durability to withstand harsh environments and ballistic threats. Steel is also used in the manufacturing of firearms and ammunition, ensuring their robustness and reliability. Additionally, steel is employed in the construction of military-grade infrastructure, including fortifications, bunkers, and naval vessels, which require high levels of protection and resilience. Overall, steel plays a crucial role in enhancing the defense capabilities and safety of armed forces worldwide.

- Q: How do steel products contribute to the telecommunications and networking industry?

- Steel products play a crucial role in the telecommunications and networking industry by providing the necessary infrastructure for transmitting and distributing data. Steel towers and poles are used to support antennas and satellite dishes, enabling wireless communication and connectivity. Additionally, steel cable trays and racks are utilized for organizing and protecting cables in data centers and telecom facilities. In essence, steel products provide the backbone for the efficient functioning of telecommunications and networking systems, facilitating reliable and high-speed communication worldwide.

- Q: How are steel plates used in the fabrication of storage tanks?

- Steel plates are used in the fabrication of storage tanks as they provide a strong and durable material that can withstand the pressure and weight of the stored contents. The plates are cut and welded together to form the tank's structure, ensuring a secure and leak-proof container for storing various substances such as liquids or gases.

- Q: How is steel used in the manufacturing of railway tracks?

- Steel is used in the manufacturing of railway tracks due to its high strength and durability. It is used to create the rails, which provide a smooth and stable surface for trains to travel on. Additionally, steel is also used in the construction of other track components such as sleepers, fasteners, and switches, ensuring a reliable and long-lasting railway infrastructure.

- Q: What are the different types of steel bar grating materials?

- There are several different types of steel bar grating materials, including carbon steel, stainless steel, and aluminum.

- Q: How do steel products contribute to the recreational and sports industry?

- Steel products contribute to the recreational and sports industry by providing durable and resilient materials for the construction of various sporting facilities and equipment. From stadiums and arenas to bleachers, fencing, and goalposts, steel structures offer strength and stability necessary for hosting large-scale sporting events. Additionally, steel is commonly used in the manufacturing of sports equipment such as bicycles, golf clubs, tennis racquets, and even roller coasters. Its robust nature ensures longevity, safety, and enhanced performance, making steel an indispensable component in the recreational and sports industry.

- Q: What are the different types of steel coatings?

- There are various types of steel coatings, including galvanized coatings, epoxy coatings, powder coatings, and organic coatings.

Send your message to us

AISI420 Steel Shot 8mm G100 Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords