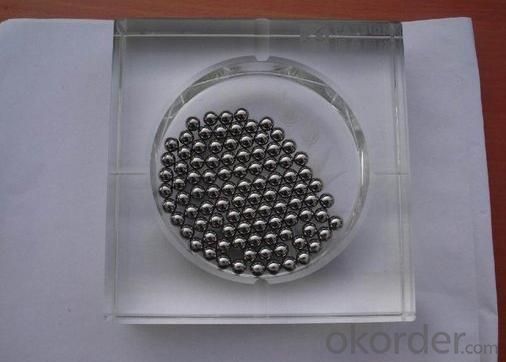

430 Stainless Steel Ball

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons pc

- Supply Capability:

- 1000 Tons Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Ball

MAIN PRODUCTS:

1. Material: AISI304, 316L, 420C, 430, 440C

2. Steel ball, with material AISI 1008-1086.

3. Chrome steel ball,with material: AISI52100

4. Flying saucer steel ball

5. Precision casting, including auto parts, machine parts, hardware handles, etc.

CHARACTER OF PRODUCTS:

1.The Grade of our products is from G10 to G1000

2.The dimension is from 0.5 mm to 25.4 mm.

3.The products from us are widely used in several industries, such as hardware, sliders, ball bearing lead screw, wheels, toys, bicycles, bearings, trust bearings pulleys, chemical industries, etc.

DETAIL SPECIFICATION:

|

Item |

SS304,316L,420C,440C Stainless steel ball |

|

Category |

Stainless Steel Ball |

|

Material |

AISI 420 430 440 SS304 316L |

|

Size |

0.5mm--25.4mm, 1/4",3/16",5/32",1/8",7/32",5/16",7/8",1" |

|

Grade |

G100-G3000 |

|

Hardness ( HRC) |

HRC58-65 |

|

Application |

Bicycle, bearing, pulley, slide, handcraft, shelf, luggage, hardware, grinding media |

|

Standard |

GB/T-308-2002, GB/T1148-93 |

|

Matched Standard |

DIN, JIS, ASME |

|

Certification |

ISO |

|

Packing |

Oily packing in pouch packing,plastic/tin box packing 1, 25kg/carton with steel pallet packing 2,25kg/carton without steel pallet packing 3,10kg/box then in wooden case packing 4,250kg/ steel drum packing or according to customers' requirement |

|

Place of original |

Shandong province, China |

|

Delivery |

Within 30 days or confirmed while placing order |

- Q: Are stainless steel balls available in different colors?

- Different colors of stainless steel balls are available. Although the natural color of stainless steel is silver, there are several techniques to alter its color. These techniques include powder coating, electroplating, and anodizing. Powder coating entails applying a colored powder onto the stainless steel surface, which is then baked to produce a long-lasting and appealing finish. Electroplating involves depositing a layer of metal, such as chrome or gold, onto the stainless steel surface, resulting in a new color. On the other hand, anodizing involves creating a protective oxide layer on the stainless steel surface, which can be dyed in various colors. Consequently, stainless steel balls can be customized to meet different preferences and applications.

- Q: Are stainless steel balls used in cosmetic products?

- Yes, stainless steel balls are commonly used in cosmetic products. They are often found in products like roll-on deodorants, facial serums, and liquid foundation. These balls serve as applicators or mixers, allowing for easy and precise product distribution.

- Q: What is the size range of stainless steel balls?

- Depending on the application and industry, the size of stainless steel balls can vary. Typically, these balls come in a range of sizes, from 1 millimeter to several inches in diameter. They find widespread use in automotive, aerospace, medical, and manufacturing sectors. Precision instruments and bearings often employ smaller stainless steel balls, whereas valves, pumps, and other industrial equipment utilize larger ones. Moreover, custom-made stainless steel balls can be tailored to meet specific size needs for specialized applications.

- Q: What are the different types of stainless steel ball valves?

- There are several different types of stainless steel ball valves that are used in various applications. Some of the common types include: 1. Two-way ball valves: These valves have a single inlet and outlet and are used for on/off control of fluid flow. They have a simple design with a lever or handle that rotates a ball inside the valve body to control the flow. 2. Three-way ball valves: As the name suggests, these valves have three ports and are used for diverting or mixing flows. They can be used to control the flow between two inlets and one outlet or vice versa. This type of valve is commonly used in applications where flow direction needs to be changed frequently. 3. Full port ball valves: Full port ball valves have a larger ball and opening, allowing for maximum flow capacity. These valves minimize pressure drop and are often used in applications where high flow rates are required, such as in industrial processes or large-scale plumbing systems. 4. Reduced port ball valves: In contrast to full port valves, reduced port ball valves have a smaller ball and opening. This design reduces the flow capacity but provides better control over the flow rate. These valves are commonly used in applications where precise flow control is essential, such as in small-scale plumbing systems or laboratory setups. 5. Floating ball valves: In this type of valve, the ball is not fixed to the valve stem but floats between the two seats. The pressure of the flowing fluid pushes the ball against the seat, creating a tight seal. Floating ball valves are generally used in low-pressure applications. 6. Trunnion mounted ball valves: These valves have a fixed ball that is supported by two trunnions or shafts. The trunnions provide additional support and reduce the operating torque required to rotate the ball. Trunnion mounted ball valves are commonly used in high-pressure and large-diameter applications. It is important to consider the specific requirements of your application when selecting a stainless steel ball valve. Factors such as pressure rating, temperature range, flow capacity, and corrosion resistance should be taken into account to ensure the valve performs optimally in the intended environment.

- Q: Can stainless steel balls be used in magnetic stirrers?

- Indeed, magnetic stirrers are compatible with stainless steel balls. The reason lies in the ferromagnetic nature of stainless steel, enabling it to be magnetized. Magnetic stirrers employ a magnetic field to rotate a magnetic stir bar or bead suspended in a liquid. In place of magnetic stir bars, stainless steel balls can be utilized as they offer convenient magnetization and efficient stirring within a solution. Nonetheless, it is crucial to consider the dimensions and weight of the stainless steel balls in accordance with the particular magnetic stirrer being utilized, to guarantee adequate rotation and thorough mixing.

- Q: How do stainless steel balls handle high-speed rotations?

- Stainless steel balls are well-suited for high-speed rotations due to their excellent strength, hardness, and corrosion resistance. These properties allow the balls to withstand intense centrifugal forces, maintain their shape, and provide reliable performance in applications such as bearings, valves, and precision machinery.

- Q: Are stainless steel balls used in chemical dispensing equipment?

- Yes, stainless steel balls are commonly used in chemical dispensing equipment. Stainless steel is preferred in these applications because it offers excellent corrosion resistance and durability. The balls are used in valves, pumps, and other dispensing mechanisms to ensure smooth fluid flow and prevent leakage. Additionally, stainless steel is compatible with a wide range of chemicals, making it a suitable choice for chemical dispensing equipment in various industries such as pharmaceuticals, food and beverage, and water treatment.

- Q: How do stainless steel balls perform in high-pressure applications?

- Known for their exceptional performance in high-pressure applications, stainless steel balls possess excellent corrosion resistance and high strength. As a result, they can endure extreme pressures without deformation or breakage, making them suitable for use across a wide range of industries, including oil and gas, aerospace, and automotive. In the realm of high-pressure applications, stainless steel balls find frequent use as valve components, check valves, and ball bearings. These balls are specifically designed to handle intense pressures while delivering reliable and consistent performance. The hardness and smooth surface finish of stainless steel balls enable them to resist wear and withstand the abrasive forces encountered in high-pressure environments. Moreover, stainless steel balls exhibit good heat resistance, ensuring their structural integrity is maintained even when exposed to elevated temperatures. This property proves crucial in applications where high-pressure fluids or gases generate significant heat. Additionally, stainless steel balls possess low friction coefficients, reducing energy loss due to friction and facilitating efficient operation within high-pressure systems. A further advantage lies in their non-magnetic nature, which prevents interference with sensitive electronic or magnetic equipment commonly found in high-pressure applications. Overall, stainless steel balls excel in high-pressure environments due to their durability, corrosion resistance, heat resistance, low friction, and non-magnetic properties. These qualities render them an ideal choice for diverse high-pressure applications, guaranteeing reliable and long-lasting performance even under extreme conditions.

- Q: Are stainless steel balls suitable for marine applications?

- Yes, stainless steel balls are suitable for marine applications. Stainless steel is known for its corrosion resistance properties, making it an ideal material for use in marine environments where exposure to salt water, moisture, and other harsh conditions is common. Stainless steel balls are not only resistant to corrosion, but they also maintain their strength and durability, making them suitable for various marine applications such as bearings, valves, pumps, and other marine equipment. Additionally, stainless steel balls are easy to clean and maintain, providing long-lasting performance in marine settings.

- Q: Are stainless steel balls resistant to UV radiation?

- Yes, stainless steel balls are generally resistant to UV radiation. Stainless steel is known for its corrosion resistance and durability, and it is also highly resistant to UV radiation. The chromium content in stainless steel creates a protective oxide layer on the surface of the material, which helps prevent damage from UV rays. This oxide layer acts as a barrier, shielding the stainless steel from harmful UV radiation and preventing it from degrading or discoloring over time. Therefore, stainless steel balls can be considered as a suitable choice for applications where UV resistance is required.

Send your message to us

430 Stainless Steel Ball

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons pc

- Supply Capability:

- 1000 Tons Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords