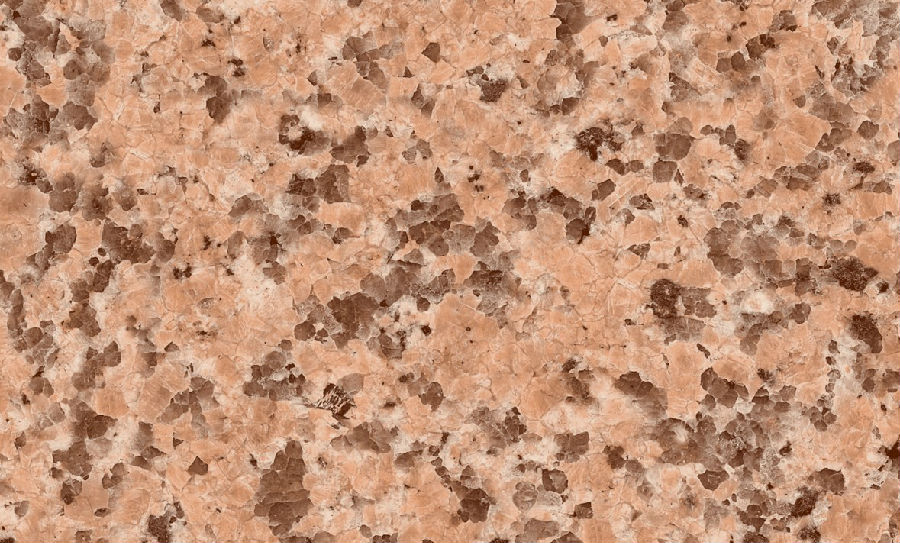

High Quality Wooden Pattern Printing Steel Plate-0.60mm*1000mm Z40g

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality Wooden Pattern Printing Steel Plate-0.60mm*1000mm Z40g

1.Thickness:0.16-2.0mm

2.Width:600-1500mm

3.Material: SGCC,SGCD,SECC,SECD,DX51D+Z

4.Zinc coating:40-275G/M2

5.Surface Structure: galvanized ,zero spangle, regular spangle or normal spangle

6.Surface treatment: chromated and oiled, chromated and non-oiled

7.Color:all RAL series

1.strong corrosion resistance

2.surface quality

3.conducive to deep processing,such as the embossed PPGI,printed PPGI&punching PPGI

4.economy and practicality

1.Refrigerator shutter &side panels, Washer, Freezers, Air conditions,

2.Rice Cooker, Microwave Ovens, Water Heaters, Sterilization Cabinets, Range Hoods

3.Computer Panels , DVD/DVB panels, TV back panel etc.

Teaching Board: whiteboard, blackboard, green board(chalk board).

Indoor Decoration: Fireproof Door, kitchen cabinet, wall decoration.

Shipping Industries: Ship, Fecht, Marine.

- Q: Can steel strips be used for making springs or clips?

- Yes, steel strips can be used for making springs or clips. Steel strips are often chosen for their strength, durability, and flexibility, making them suitable for applications that require springs or clips with tension or fastening capabilities.

- Q: How are steel strips tested for edge condition?

- Steel strips are tested for edge condition using various methods to ensure their quality and suitability for specific applications. One common method is visual inspection, where trained personnel examine the edges of the steel strips for any defects or irregularities. This includes checking for burrs, cracks, roughness, or any other imperfections that could affect the performance of the steel strip. Another method used is to conduct a physical measurement of the edge condition. This can be done using specific tools such as calipers or micrometers to measure the dimensions of the edges. The measurements are compared against the required specifications to determine if the edge condition meets the desired standards. Furthermore, steel strips can be tested for edge condition using non-destructive testing techniques such as ultrasonic testing or magnetic particle inspection. Ultrasonic testing involves sending high-frequency sound waves through the steel strip and analyzing the reflected waves to detect any flaws in the edges. Magnetic particle inspection, on the other hand, uses magnetic fields and iron particles to identify any surface or near-surface defects in the edges. In some cases, the steel strips may also undergo mechanical testing, where samples are subjected to various stress conditions to evaluate the edge condition's strength and durability. This can include tests like bend tests, impact tests, or hardness tests, which assess the ability of the edges to withstand different loads and forces. Overall, a combination of visual inspection, physical measurement, non-destructive testing, and mechanical testing is employed to thoroughly evaluate the edge condition of steel strips and ensure their quality and suitability for different applications.

- Q: Can steel strips be used in electrical motors?

- Yes, steel strips can be used in electrical motors. They are commonly used as laminations in the core of the motor to reduce energy losses caused by eddy currents. The steel strips are stacked together to form the core, which helps in providing a low reluctance path for the magnetic flux and enhances the overall efficiency of the motor.

- Q: How are steel strips inspected for quality and defects?

- Steel strips are inspected for quality and defects through a comprehensive process that involves various techniques and tools. One of the most common methods is visual inspection, where trained personnel carefully examine the steel strips for any visible defects such as surface imperfections, scratches, cracks, or irregularities in thickness or width. This process ensures that the strips meet the required visual standards and specifications. In addition to visual inspection, non-destructive testing (NDT) techniques are frequently employed to detect internal defects that may not be visible to the naked eye. NDT methods can include magnetic particle inspection, ultrasonic testing, eddy current testing, and dye penetrant testing. These techniques allow inspectors to identify potential defects such as internal cracks, voids, or inclusions that could compromise the quality of the steel strips. Moreover, precision measurement tools are used to ensure the dimensional accuracy of the steel strips. This can involve the use of calipers, micrometers, or laser measurement devices to verify the strip's thickness, width, and length. Any deviation from the specified dimensions is considered a quality issue and requires further investigation. Furthermore, laboratory testing is often conducted to assess the mechanical properties of the steel strips. Tensile testing is commonly performed to determine the strip's strength, elongation, and yield point. Hardness testing is also carried out to evaluate the strip's resistance to indentation or deformation. These tests help to ensure that the steel strips possess the required mechanical properties for their intended applications. Overall, the inspection of steel strips for quality and defects is a multi-step process that combines visual examination, non-destructive testing, dimensional measurement, and laboratory analysis. By employing these techniques, manufacturers can guarantee that their steel strips meet the necessary quality standards and provide reliable and defect-free products to their customers.

- Q: What are the different testing methods used for steel strips?

- Some of the different testing methods used for steel strips include tension testing, hardness testing, dimensional testing, surface roughness testing, and chemical analysis. These methods help assess the strength, durability, and quality of the steel strips, ensuring they meet the required specifications and standards.

- Q: How do steel strips contribute to formability in various applications?

- Steel strips have various contributions to formability in multiple applications. Firstly, their high ductility allows for easy bending and shaping without cracking or breaking, enabling manufacturers to create intricate designs for automotive body panels, appliances, and construction materials. In addition, steel strips exhibit excellent elasticity, ensuring they can return to their original shape after deformation. This property is particularly important in applications requiring repetitive bending or shaping, such as the production of springs or hinges. Furthermore, steel strips offer easy joinability and welding, providing flexibility in their application. This allows manufacturers to customize the length and shape of steel strips according to specific requirements, resulting in more efficient production processes and reduced material waste. Moreover, steel strips possess a favorable strength-to-weight ratio, meaning they are strong while remaining relatively lightweight. This characteristic makes them suitable for applications where strength and weight balance is crucial, such as in the aerospace industry. Lastly, steel strips can be coated or treated to enhance their formability and corrosion resistance. Coatings like galvanization or zinc plating provide an extra layer of protection against rust and corrosion, ensuring the longevity and durability of steel strips in various environments. Overall, the formability of steel strips plays a vital role in their extensive range of applications. Their ductility, elasticity, joinability, strength-to-weight ratio, and ability to be coated contribute to their versatility, making them an ideal choice for numerous industries.

- Q: How are steel strips used in the manufacturing of automotive fuel systems?

- Steel strips are commonly used in the manufacturing of automotive fuel systems for various purposes such as forming the framework of fuel tanks, creating fuel lines, and producing brackets and support structures. The high strength and durability of steel strips make them ideal for withstanding the pressure and corrosive nature of fuel, ensuring the safety and longevity of the fuel system components.

- Q: How are steel strips used in the renewable energy industry?

- Steel strips are used in the renewable energy industry for various purposes such as manufacturing wind turbines, solar panels, and other renewable energy infrastructure. They are used to create the structural components, support frames, and mounting systems that are essential for the installation and operation of renewable energy equipment.

- Q: What is a steel strip?

- A steel strip is a flat and thin piece of steel that is typically produced through a process called hot rolling or cold rolling. It is formed by passing a heated or cooled steel billet through a series of rollers, which gradually reduce its thickness and shape it into a long and narrow strip. Steel strips are commonly used in various industrial applications due to their strength, durability, and versatility. They can be found in products such as automotive parts, construction materials, electrical appliances, and packaging materials. The strip's width can vary based on its intended use, and it can also be further processed or treated to enhance certain properties or achieve specific characteristics, such as surface finish, hardness, or corrosion resistance. Overall, steel strips are essential components in many manufacturing processes and play a crucial role in numerous industries.

- Q: How are steel strips processed for surface welding?

- Steel strips are processed for surface welding through a series of steps to ensure a clean and smooth welding surface. Firstly, the steel strips are cleaned thoroughly to remove any dirt, grease, or rust using solvents or degreasers. This step is crucial as any contaminants on the surface can negatively impact the quality of the weld. After cleaning, the steel strips may undergo a process called pickling, where they are immersed in an acid solution to remove any scale or oxides formed during the manufacturing process. Pickling helps to create a chemically clean surface, free from impurities, which is essential for achieving a strong and durable weld. Following pickling, the steel strips are often subjected to surface grinding or sandblasting. Surface grinding involves removing a thin layer of the metal's surface to create a smooth and even finish. Sandblasting, on the other hand, utilizes high-pressure air or steam to propel abrasive particles onto the steel strips, effectively removing any remaining contaminants and providing a textured surface that promotes better adhesion for the welding process. Once the steel strips have been thoroughly cleaned and prepared, they are ready for surface welding. This can be done using various welding techniques, such as MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding. These methods involve creating an electric arc between the steel strips and a consumable electrode, which melts and fuses the metal together. The welding process requires careful control of heat, speed, and pressure to ensure a strong and uniform bond. In conclusion, the processing of steel strips for surface welding involves cleaning, pickling, and surface preparation steps to remove contaminants, promote adhesion, and create an ideal surface for welding. This ensures that the resulting weld is of high quality, with excellent strength and durability.

Send your message to us

High Quality Wooden Pattern Printing Steel Plate-0.60mm*1000mm Z40g

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords