Stainless Steel Coil SS 201/304/316/304L/316L/309S/310S/430 stainless steel coil

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Stainless Steel Coil Description

The surface brightness and flatness of no2B is better than no2D. then through a special

surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses.

2.Main Features of the Stainless Steel Coil

• Tensile strength: not less than 520

• Provides that non-proportional extension strength: not less than 205

• Elongation: not less than 35; 3 density: 7.98

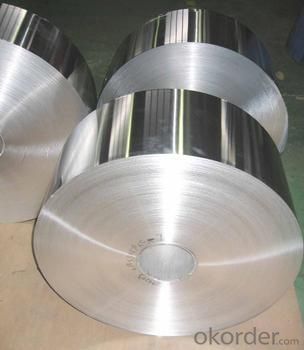

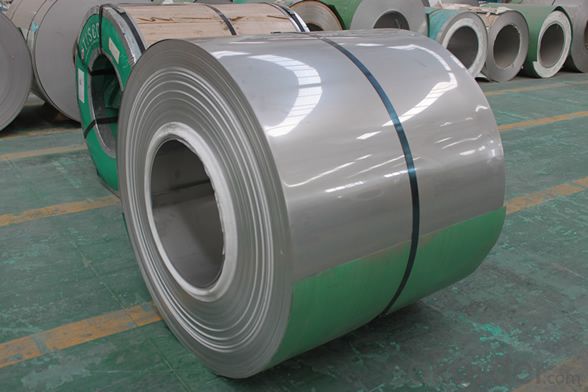

3. Stainless Steel Coil Images

4. Stainless Steel Coil Specification

| Grade: | 200series.300series. | Standard: | JIS,AISI,ASTM | Length: | as request |

| Thickness: | 0.3-3mm | Width: | 30-2000mm | Place of Origin: | Shanxi China (Mainland) |

| Brand Name: | CNBM | Model Number: | ss201/304/316/304L/316L/309S/310S/430 | Type: | Coil |

| Application: | hardware, foodstuff, manufacture, medic | Certification: | SGS | Item: | ss202/304/316/309s/310/410/420 stainless steel sheet |

| Packaging: | Export standard package or as your requirement | Delivery: | In 15 days | Stock: | Available |

5.FAQ of Stainless Steel Coil

①Who are you?

We are the manufacturer! We produce stainless steel products

with high quality & very competitive price!Please feel free to

contact us for more information!

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

③How about your company?

A world class manufacturer & supplier of castings forging in Stainless Steel Sheet,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

- Q: How are steel strips used in the manufacturing of bearings?

- Steel strips are used in the manufacturing of bearings as they act as the raw material for producing the inner and outer rings of the bearing. These strips are shaped, machined, and heat-treated to form the necessary ring components, which provide support, alignment, and enable the smooth rotation of the bearing.

- Q: Reasons for black side of hot strip galvanizing

- The content of zinc chloride in plating bath is too low, which leads to some parts can not be plated and lead to local blackening.

- Q: How are steel strips used in the production of hand tools?

- Due to their durability and versatility, steel strips find wide application in the manufacturing of hand tools. These strips are typically made from high-quality steel alloys, which offer exceptional strength and wear resistance. In the production process, steel strips are initially cut into desired dimensions and then undergo various forming operations such as bending, stamping, or rolling. This allows the strips to take on the specific shapes required for hand tool components, including blades, handles, or shafts. The flexibility of steel strips enables the production of a diverse range of tool designs to meet varied application needs. Once the components are shaped, they undergo further processing through heat treatment, which enhances their hardness and toughness. This treatment ensures that the hand tools can endure significant force, impact, and wear during use, making them highly durable and long-lasting. Steel strips are also utilized in the production of hand tool accessories, such as springs, clips, or fasteners. These components play crucial roles in enhancing the functionality and usability of the tools. For example, springs made from steel strips provide the necessary tension or pressure required for certain hand tools, like pliers or clamps. Furthermore, steel strips can be coated or plated with protective finishes, such as chrome or nickel, to enhance their corrosion resistance and improve the overall aesthetics of the hand tools. This added layer of protection ensures that the tools remain in good condition even in challenging working environments. In summary, steel strips are indispensable in the production of hand tools as they provide the necessary strength, durability, and versatility for various applications. From blades to handles, these strips enable the creation of high-quality tools that can withstand rigorous use and deliver exceptional performance.

- Q: What are the different thicknesses available for steel strips?

- The different thicknesses available for steel strips vary depending on the application and industry requirements. Common thicknesses can range from very thin, such as 0.001 inches (0.0254 mm), to thicker options like 0.25 inches (6.35 mm) or more. However, it is important to note that steel strips can be manufactured in a wide range of thicknesses to meet specific project needs.

- Q: What is the fatigue resistance of steel strips?

- The fatigue resistance of steel strips refers to the ability of these strips to withstand repeated cycles of stress or strain without experiencing failure. Steel strips are known for their high fatigue resistance, which makes them suitable for various applications that involve constant or cyclic loading. The fatigue resistance of steel strips depends on several factors, including the composition, microstructure, and surface condition of the steel. Additionally, factors such as the load magnitude, frequency, and duration of the cyclic loading also impact the fatigue resistance. Steel strips are typically designed to have a high fatigue limit, meaning they can endure a large number of stress cycles without failure. This characteristic makes steel strips highly desirable in industries where fatigue failure is a concern, such as automotive, aerospace, construction, and manufacturing. Through proper design, manufacturing processes, and material selection, steel strips can achieve excellent fatigue resistance, ensuring their long-term performance and reliability in demanding applications.

- Q: How are steel strips used in the production of wind turbines?

- Steel strips are used in the production of wind turbines for various purposes such as making the tower, rotor blades, and other structural components. These strips are shaped, welded, and assembled to create the tower sections, providing the necessary height and strength to support the turbine. Additionally, steel strips are often used in the manufacturing of rotor blades, which require strong, lightweight materials to efficiently capture wind energy.

- Q: What are the common standards and specifications for steel strips?

- There are several common standards and specifications for steel strips that are widely recognized and adhered to in the industry. These standards ensure that steel strips meet specific requirements for quality, strength, and other properties. Some of the most common standards and specifications for steel strips include: 1. ASTM A109/A109M: This standard covers cold-rolled carbon steel strip, which is commonly used for various applications, including automotive components, electrical parts, and appliances. It specifies the chemical composition, mechanical properties, and tolerances for dimensional and surface characteristics. 2. ASTM A568/A568M: This standard covers general requirements for steel sheet and strip, including hot-rolled, cold-rolled, and coated steel sheets and strips. It provides specifications for the dimensions, tolerances, and mechanical properties of these products. 3. EN 10130: This European standard specifies the requirements for cold-rolled low-carbon steel strips. It defines the chemical composition, mechanical properties, and tolerances for dimensions and shape. EN 10130 also covers requirements for surface quality, including roughness and flatness. 4. JIS G 3141: This Japanese Industrial Standard sets the specifications for cold-reduced carbon steel sheets and strips. It outlines the chemical composition, mechanical properties, and dimensions of these products. JIS G 3141 also includes requirements for surface finish, including roughness and appearance. 5. DIN 1624: This German standard specifies the properties and dimensions of cold-rolled steel strip. It covers the chemical composition, mechanical properties, and tolerances for thickness, width, and length. DIN 1624 also includes requirements for surface quality and flatness. These common standards and specifications ensure that steel strips are manufactured to consistent and reliable quality standards. Manufacturers, suppliers, and end-users can refer to these standards to ensure that the steel strips they are using meet the necessary requirements for their specific applications.

- Q: What are the load-bearing capacities of steel strips?

- The load-bearing capacities of steel strips vary depending on their thickness, width, and the type of steel used. Steel strips are designed to withstand significant amounts of weight or load without bending or breaking. The load-bearing capacity is typically measured in terms of the maximum load that the strip can bear per unit of length or area, usually given in pounds or tons. The load-bearing capacity of a steel strip can be determined by considering various factors, such as the yield strength, ultimate tensile strength, and elastic modulus of the steel material. These properties dictate the strip's ability to resist deformation under load. Different steel grades have different load-bearing capacities. For instance, high-strength steel strips, such as those made from alloyed or heat-treated steel, generally have higher load-bearing capacities compared to standard carbon steel strips. To accurately determine the load-bearing capacity of a specific steel strip, it is necessary to consult engineering design codes, standards, or technical specifications. These resources provide detailed information on load-bearing capacities based on the specific dimensions and properties of the steel strip. It is important to note that load-bearing capacities should be considered in conjunction with other factors, such as safety factors, environmental conditions, and the intended application of the steel strip. Consulting with a structural engineer or a knowledgeable professional is highly recommended to ensure the appropriate selection and usage of steel strips for a specific load-bearing application.

- Q: How are steel strips leveled or straightened?

- Steel strips are typically leveled or straightened through a process called leveling or flattening. This involves passing the strips through a series of rolls that apply pressure and tension to remove any deformations and ensure their flatness.

- Q: What are the specifications for steel strips used in the production of watches?

- The specifications for steel strips used in the production of watches typically include a specific alloy composition, precise dimensions and thickness, high strength and durability, excellent corrosion resistance, and a smooth surface finish. Additionally, these steel strips may need to meet certain industry standards and regulations to ensure their suitability for watch production.

Send your message to us

Stainless Steel Coil SS 201/304/316/304L/316L/309S/310S/430 stainless steel coil

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords