Steel roof sheets cold rolled china trade goods

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 52643 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Cold rolled sheet products have been available for many, many years, and have been successfully used for a multitude of

applications. Today's cold rolled sheet products are much improved over those used in the past. They offer better control of

thickness, shape, width, surface finish, and other special quality features that compliment the emerging need for highly

engineered end use applications.

It is suited to formation by bending or drawing, which enables complex parts to be produced in good repeatable conditions and

intended for indoor use.

These cold rolled steel coil/sheet grades have excellent formability, which facilitates cold forming operations, and are ideal for deep

drawing. Our range of steels for cold forming offer excellent forming performance, due to the low scattering of their chemical composition

and their mechanical properties, which guarantees processing consistency.

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc, construction &

building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving, containers, drums

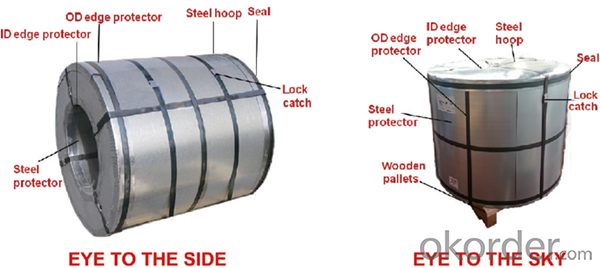

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services:

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we

have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will

provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing

as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q: Can steel sheets be perforated or punched?

- Yes, steel sheets can be perforated or punched. Perforating or punching involves creating holes or designs in the steel sheet using specialized tools or machinery. This process is commonly used in various industries such as construction, automotive, and manufacturing to achieve specific functionality or aesthetics in the steel sheet.

- Q: Are the steel sheets suitable for electrical enclosures?

- Indeed, electrical enclosures find steel sheets to be quite suitable. Steel, being a remarkably rugged and robust material, offers unparalleled safeguarding for electrical components. Its resistance to impact, corrosion, and extreme temperatures renders it a truly optimal selection for housing delicate electrical equipment. Furthermore, steel sheets can be conveniently fashioned and tailored to meet precise design specifications, guaranteeing a flawless fit for the electrical enclosure. In essence, steel sheets provide the essential strength, durability, and protection required to effectively house electrical components.

- Q: What are the different sheet metal folding techniques for steel sheets?

- There are several sheet metal folding techniques for steel sheets, including the following: 1. V-Bending: This technique involves bending the sheet along a V-shaped groove. The sheet is placed between a punch and a die, and as the punch descends, it forces the sheet into the die, creating the desired bend. 2. Edge Bending: Also known as flanging, edge bending involves bending the edges of the sheet to form a flange. This technique is commonly used for joining two or more sheets together or creating a stiffening edge. 3. Box Folding: Box folding is used to create 3D shapes, such as boxes or enclosures. It involves folding the sheet along multiple bends to form a hollow structure. 4. Hemming: Hemming is a technique used to create a folded edge on the sheet, typically for aesthetic purposes or to provide additional strength. It involves folding the edge of the sheet back onto itself. 5. Roll Bending: Roll bending is a technique used to achieve curved bends in the sheet. The sheet is passed through a series of rollers, which gradually bend it to the desired curvature. These are just a few of the most commonly used sheet metal folding techniques for steel sheets. The choice of technique depends on the specific requirements of the project and the desired outcome.

- Q: What is the average cost of steel sheets per square foot?

- The cost of steel sheets per square foot can differ significantly due to various factors, including the type of steel, thickness, size, and market conditions. Nevertheless, as of 2021, the price range for steel sheets averages from $5 to $20 per square foot. It is crucial to acknowledge that this estimate is broad, and prices may vary depending on the location, supplier, and other market aspects. Consequently, it is advisable to collect quotes from multiple suppliers in order to obtain an accurate and current cost for steel sheets per square foot.

- Q: What are the different methods of surface cleaning for steel sheets?

- There are several methods of surface cleaning for steel sheets, including mechanical cleaning techniques such as abrasive blasting or grinding, chemical cleaning using solvents or acids, and electrochemical cleaning methods like electrolysis or pickling. Each method is chosen based on the specific requirements and condition of the steel surface to effectively remove dirt, rust, scale, or other contaminants.

- Q: Are steel sheets suitable for industrial machinery components?

- Yes, steel sheets are commonly used for industrial machinery components due to their high strength, durability, and versatility. They provide excellent structural integrity, resistance to wear and tear, and can withstand heavy loads and extreme conditions commonly found in industrial settings. Additionally, steel sheets can be easily formed, welded, and machined to meet specific requirements, making them a preferred choice for manufacturing various machinery components.

- Q: What is the difference between a smooth and textured steel sheet?

- A smooth steel sheet and a textured steel sheet differ primarily in their surface appearance and feel. A smooth steel sheet has a flat and unblemished surface, with no visible patterns or textures. It provides a sleek and polished look, making it suitable for applications where aesthetics are important, such as architectural designs, interior decoration, or automotive body parts. On the other hand, a textured steel sheet has a surface that is intentionally manipulated to create patterns or textures. These patterns can range from simple lines or ridges to more intricate designs like diamond or checker plate patterns. The textured surface adds visual interest and can also enhance the sheet's functionality by providing improved grip or traction. The choice between a smooth and textured steel sheet depends on the intended use and desired outcome. Smooth steel sheets are often used in applications where a clean and polished look is desired, such as in high-end appliances or furniture. They are also commonly used in industries where a smooth surface is crucial for efficient processes, like food processing or packaging. Textured steel sheets, on the other hand, are preferred in applications where both functionality and aesthetics are important. For example, they are commonly used in flooring or stairs, as the textured surface provides additional grip and reduces the risk of slipping. These sheets are also found in truck beds, ramps, or walkways where enhanced traction is necessary. In summary, the primary difference between a smooth and textured steel sheet lies in their surface appearance and functionality. Smooth steel sheets provide a sleek and unblemished look, while textured steel sheets feature intentional patterns or textures that can enhance grip, traction, and visual interest. The choice between the two depends on the specific application requirements and desired outcome.

- Q: Can the steel sheets be used for kitchen countertops?

- Yes, steel sheets can be used for kitchen countertops.

- Q: Are steel sheets resistant to extreme weather conditions?

- Yes, steel sheets are generally known for their high resistance to extreme weather conditions. Due to their durable and robust nature, they can withstand harsh temperatures, heavy rain, strong winds, and even hailstorms without significant damage.

- Q: What is the process of cold rolling steel sheets?

- The process of cold rolling steel sheets involves passing hot-rolled steel through a set of rollers at room temperature to reduce its thickness and improve its surface finish. This process is typically done in multiple passes, gradually reducing the thickness of the steel while maintaining its strength. Cold rolling also imparts desirable mechanical properties to the steel, such as increased hardness and improved dimensional accuracy.

Send your message to us

Steel roof sheets cold rolled china trade goods

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 52643 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords