Steel Rebar Hs Code Import Duty and Taxes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel Rebar Hs Code Import Duty and Taxes

Description of Steel Rebar HS Code:

1, Diameter: 5.5mm-10mm rounds reinforcing steel bar

10m- 40 rods reinforcing Steel Rebar HS Code

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of Steel Rebar HS Code:

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

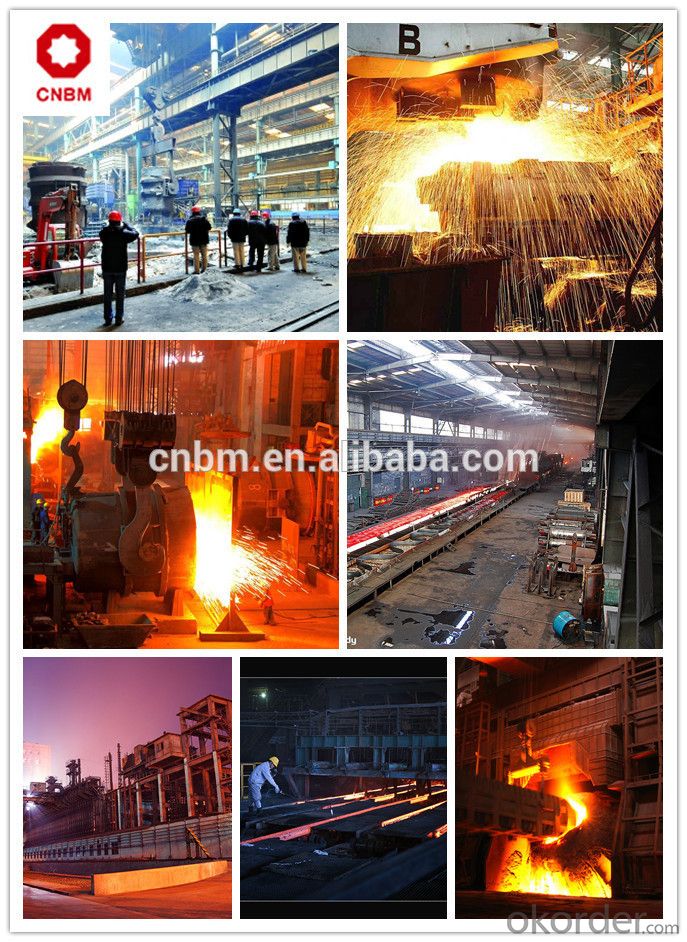

Product Show of Steel Rebar HS Code:

Workshop

Company Information:

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ:

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Contact Us:

- Q: How is special steel used in the production of heat exchangers?

- Special steel is widely used in the production of heat exchangers due to its unique properties that make it ideal for this application. Heat exchangers are devices designed to transfer heat from one medium to another, and special steel offers several advantages in this process. Firstly, special steel has excellent thermal conductivity, meaning it can efficiently transfer heat from one fluid to another. This property is crucial for heat exchangers, as it allows for the rapid and efficient exchange of thermal energy. Additionally, the high corrosion resistance of special steel makes it highly suitable for heat exchanger applications. Heat exchangers often come into contact with corrosive fluids or gases, and regular steel may corrode over time. However, special steel is specifically designed to resist corrosion, ensuring the longevity and reliability of the heat exchanger. Furthermore, special steel offers exceptional strength and durability, allowing heat exchangers to withstand high pressures and temperatures. Heat exchangers often operate in challenging environments, and special steel can withstand these harsh conditions without compromising its structural integrity. Special steel also provides excellent weldability and formability, making it easier to manufacture complex heat exchanger designs. Its versatility allows for the production of heat exchangers in various shapes and sizes, catering to the specific needs of different industries. In summary, special steel is used in the production of heat exchangers due to its high thermal conductivity, corrosion resistance, strength, durability, weldability, and formability. These properties ensure efficient heat transfer, resistance to corrosion, and the ability to withstand harsh operating conditions, making special steel an ideal material for heat exchanger applications.

- Q: What are the environmental impacts of producing special steel?

- The environmental impacts of producing special steel can include air pollution from emissions released during the steelmaking process, such as carbon dioxide, sulfur dioxide, and nitrogen oxide. Additionally, the extraction of raw materials for steel production, such as iron ore and coal, can result in deforestation, habitat destruction, and water pollution. The energy-intensive nature of steel production also contributes to greenhouse gas emissions and climate change. Proper waste management and implementation of sustainable practices can mitigate some of these environmental impacts.

- Q: How does special steel contribute to reducing product failure?

- Special steel contributes to reducing product failure in several ways. Firstly, special steel is known for its superior strength and durability, which makes it less prone to breakage or deformation under stress. This ensures that products made with special steel can withstand heavy loads or harsh environments without failing. Additionally, special steel often has enhanced corrosion resistance properties, protecting products from rust or degradation over time. This helps to extend the lifespan of the product and reduce the chances of failure due to corrosion. Furthermore, special steel can be tailored to specific applications, allowing manufacturers to choose the right type of steel with the required characteristics for their products. Whether it's high temperature resistance, excellent wear resistance, or improved toughness, special steel can be customized to meet the specific demands of a product, reducing the likelihood of failure in its intended use. In summary, special steel's superior strength, corrosion resistance, and customizable properties make it an essential material in industries where product failure is a critical concern, ultimately contributing to reducing the risk of failures and enhancing overall product reliability.

- Q: How is special steel used in the marine supply chain?

- Special steel is used extensively in the marine supply chain due to its exceptional strength, corrosion resistance, and durability. It is utilized in the construction of various marine components such as ship hulls, propeller shafts, offshore platforms, and marine equipment. Special steel ensures the structural integrity and longevity of these critical marine structures, enabling safe and efficient operations in harsh and corrosive marine environments.

- Q: How is corrosion-resistant stainless steel used in the production of marine equipment?

- Corrosion-resistant stainless steel is extensively used in the production of marine equipment due to its ability to withstand the harsh and corrosive marine environment. It is commonly utilized in the construction of ship hulls, propellers, valves, pumps, and various other components that are constantly exposed to saltwater and other corrosive elements. The stainless steel's resistance to corrosion helps to ensure the longevity and reliability of marine equipment, reducing maintenance and replacement costs, and contributing to the overall safety and efficiency of maritime operations.

- Q: What are the main factors affecting the machinability of special steel?

- The machinability of special steel, which refers to its ability to be easily cut, shaped, and formed, is influenced by several key factors. 1. Alloy Composition: The chemical composition of special steel plays a crucial role in its machinability. Elements such as carbon, chromium, nickel, and molybdenum can significantly affect the material's hardness, toughness, and cutting properties. Higher carbon content, for example, can increase the hardness of steel, making it more difficult to machine. 2. Hardness: The hardness of special steel is a critical factor in determining its machinability. Harder steels require more cutting force and generate more heat during machining, which can lead to increased tool wear and reduced efficiency. Softer steels, on the other hand, are generally easier to machine but may result in lower tool life. 3. Heat Treatment: The heat treatment process used on special steel can greatly impact its machinability. Heat treatments such as annealing, tempering, or quenching can alter the steel's microstructure and mechanical properties, affecting how it responds to cutting forces. Properly heat-treated steel can improve machinability by reducing hardness and increasing toughness. 4. Grain Size: The size and distribution of grains within the steel also affect its machinability. Fine-grained steel tends to have improved machinability compared to coarse-grained steel, as smaller grains offer more uniform cutting conditions and reduce the risk of tool damage. 5. Cutting Speed and Feed Rate: Machining parameters, including cutting speed and feed rate, directly impact the machinability of special steel. Higher cutting speeds can increase tool wear and generate excessive heat, affecting the surface finish and dimensional accuracy. Similarly, incorrect feed rates can cause chip formation problems, leading to poor machinability. 6. Cutting Tool Selection: The choice of cutting tool material and geometry is critical in achieving optimal machinability. Different tool materials, such as carbide or high-speed steel, have varying wear resistance and cutting properties. The tool geometry, including rake angle and clearance angle, also affects chip formation, cutting forces, and heat generation. 7. Lubrication and Cooling: Adequate lubrication and cooling during machining are vital to enhance machinability. Lubricants or coolants help reduce friction and heat, prolong tool life, and improve chip evacuation. They also prevent workpiece deformation and improve surface finish. Considering these factors, it is essential to carefully select the appropriate special steel grade, optimize machining parameters, and use suitable cutting tools and lubrication to achieve the desired machinability and maximize productivity.

- Q: How is special steel used in the telecommunications industry?

- Special steel is used in the telecommunications industry to manufacture various components and infrastructure. It is primarily utilized in the production of transmission towers, antenna masts, and other supporting structures for telecommunication equipment. The high strength and durability of special steel make it suitable for withstanding extreme weather conditions and providing stability to the telecommunications network. Additionally, special steel is also used in the manufacturing of cables, connectors, and other smaller components that are crucial for efficient signal transmission and communication in the industry.

- Q: Can special steel be used in the pharmaceutical manufacturing industry?

- No, special steel is not typically used in the pharmaceutical manufacturing industry. The industry requires specific materials, such as stainless steel, that meet strict regulatory requirements for cleanliness, corrosion resistance, and compatibility with pharmaceutical products.

- Q: How does special steel contribute to the robotics industry?

- The robotics industry benefits greatly from the use of special steel, which plays a vital role in its advancement. To begin with, special steel alloys possess extraordinary mechanical properties that make them ideal for manufacturing various robotic components. These alloys provide exceptional strength, durability, and resistance to wear and tear. Consequently, robots built with special steel can operate efficiently and reliably even in demanding environments like manufacturing plants or hazardous locations. Furthermore, special steel alloys offer outstanding heat resistance and thermal stability, a crucial characteristic in robotics. As robots often generate significant heat during operations, special steel components can withstand high temperatures without deforming or losing their structural integrity. This capability ensures that robots can perform optimally without the risk of mechanical failures caused by heat-related issues. Additionally, the corrosion resistance of special steel is highly advantageous for the robotics industry. Robots are increasingly being used in diverse applications such as underwater exploration, chemical handling, and outdoor environments. In such cases, exposure to moisture, chemicals, or harsh weather conditions can lead to corrosion and degradation of robot parts. By utilizing special steel alloys, manufacturers can significantly prolong the lifespan of robotic systems, reducing maintenance costs and enhancing overall reliability. Moreover, special steel's magnetic properties are invaluable in the development of magnetic sensors and actuators used in robotics. These sensors enable robots to detect and interact with their surroundings, improving their autonomy and adaptability. On the other hand, magnetic actuators enable precise control and movement in robotic systems. Special steel's magnetic properties contribute to the efficiency, accuracy, and responsiveness of these components, allowing robots to execute complex tasks with precision. In conclusion, special steel plays a vital role in the robotics industry by providing the necessary materials for manufacturing robust, high-performance, and versatile robotic systems. The use of special steel alloys enhances strength, durability, and the ability to withstand extreme conditions, ensuring the reliability, efficiency, and functionality of these machines.

- Q: How does special steel perform in corrosion fatigue conditions?

- Special steel is renowned for its exceptional performance under corrosion fatigue conditions. Corrosion fatigue refers to the detrimental effect of both corrosion and cyclic loading on materials' mechanical properties over time. However, special steel is specifically engineered and alloyed to withstand corrosion and maintain its structural integrity in these challenging circumstances. The addition of alloying elements like chromium, nickel, and molybdenum enables special steel to achieve high corrosion resistance. These elements create a protective oxide layer on the steel's surface, acting as a barrier against corrosive agents. This layer effectively prevents the infiltration of moisture, oxygen, and other corrosive substances, reducing the likelihood of corrosion initiation and propagation. Moreover, special steel exhibits remarkable fatigue strength, enabling it to endure cyclic loading without premature failure. Its unique microstructure, typically martensitic or austenitic, provides superior mechanical properties and resistance to fatigue crack initiation and propagation. Consequently, the material can withstand repeated loading cycles without compromising its structural integrity. Additionally, special steel possesses good ductility and toughness, essential properties in corrosion fatigue conditions. These characteristics allow the material to effectively absorb and distribute stress, preventing localized stress concentrations that may result in crack formation and propagation. In conclusion, special steel's exceptional performance under corrosion fatigue conditions can be attributed to its high corrosion resistance, fatigue strength, ductility, and toughness. These properties make it an ideal choice for applications involving cyclic loading and corrosive environments, such as offshore structures, marine equipment, and oil and gas pipelines.

Send your message to us

Steel Rebar Hs Code Import Duty and Taxes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords