steel props of B

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

suspended slab formwork

slab form work

concrete slab formwork

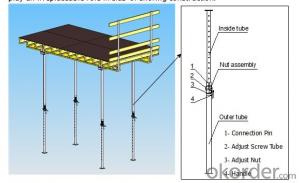

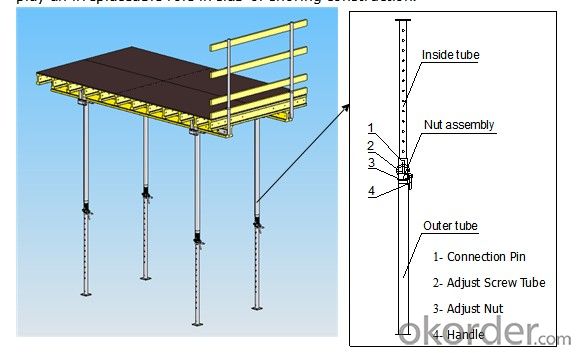

150 Aluminum Frame Early Dismantling Slab Formwork With Adjustable Prop

Description:

1. Brief introduction

Especially for projects with a large number of similar applications and open facades, Alu-slab system is the right solution. The panel is end product, no assembling on site and it is easily to build, ease of application, more important thing is, the panel is light weight, a dead lift is achieved, save time and effort.

2. Competitive advantage

① Light weight but high load bearing capacity

The panels could be transported by manual work so that it greatly reduces the aggregate cost, accelerates the erection speed, and all in all increases the aggregate benefit.

②Quickly turnover of slab panels

The early dismantling prop system speed up the turnover of the panels, minimize the investment, lower the cost, improve the working efficiency, and shorten the project period under the precondition of keeping the concrete structure and safety uninfluenced, in line with the erection requirement and ensuring the project quality.

③Cost effective with early dismantling prop system.

This early dismantling system is simple, safe and fast, saving at least 50% percent of your construction time.

3. Applications

- Q: What are the common quality control measures for steel props?

- Some common quality control measures for steel props include visual inspection for any visible defects or damage, dimensional checks to ensure proper size and alignment, load testing to determine the weight-bearing capacity, and corrosion resistance testing to assess the durability against rust and corrosion. Additionally, quality control measures may also involve material composition analysis, surface finish inspection, and adherence to industry standards and specifications.

- Q: Can steel props be used in underwater construction projects?

- Underwater construction projects can utilize steel props effectively. These props are commonly employed in construction to provide temporary support to structures or excavations. Their robust design allows them to endure heavy loads and grant stability to the construction site. The application of steel props in underwater construction projects encompasses various purposes. They can lend support to temporary structures like cofferdams or caissons, which establish a dry working environment underwater. Moreover, steel props prove useful in reinforcing underwater pipelines, platforms, and other structural elements. Nevertheless, several factors must be taken into account when employing steel props in underwater construction projects. It is crucial to ensure that these props are adequately coated or shielded against corrosion since water exposure can expedite the corrosion process. Furthermore, the material and design of the props should be appropriate for the underwater setting, considering factors such as water pressure, currents, and the presence of marine life. In addition, specialized equipment and expertise are necessary for the installation and maintenance of steel props in underwater construction projects. The involvement of divers or remotely operated underwater vehicles (ROVs) may be required for underwater installation, adjustment, or removal of the props. In conclusion, while steel props can be utilized in underwater construction projects, careful attention should be given to their design, corrosion protection, and the expertise and equipment needed for their installation and maintenance.

- Q: Can steel props be used for temporary support during beam installation?

- Indeed, steel props have the ability to serve as temporary support while installing beams. These adjustable supports, commonly utilized in construction, provide temporary support for beams, slabs, walls, and other structural components. They possess a robust and stable design, enabling them to bear heavy loads. The height of steel props can be effortlessly modified to the desired level, rendering them suitable for a range of construction tasks, including beam installation. Due to their adaptability and capacity to withstand substantial loads, steel props are an excellent option for temporary support during beam installation.

- Q: How do you prevent rust on steel props?

- To prevent rust on steel props, it is important to keep them clean and dry. Applying a protective coating such as paint or a rust inhibitor can also help to create a barrier between the steel and moisture, reducing the chances of rust formation. Regular inspections and maintenance, including addressing any scratches or chips in the coating, can further prevent rust from developing on steel props.

- Q: What are the common accessories available for steel props?

- There are several common accessories available for steel props that help enhance their functionality and safety. These accessories include: 1. Prop heads: These are used to support beams or other structural elements by providing a stable surface for them to rest on. Prop heads are adjustable and can be easily attached to the steel props. 2. Prop connectors: These connectors are used to join multiple steel props together, allowing for the creation of longer spans or supporting structures. They ensure a secure connection between the props, increasing stability and load-bearing capacity. 3. Adjustable base plates: These plates are attached to the bottom of the steel props and provide a wider surface area to distribute the load. They can be adjusted to compensate for uneven ground or to achieve the desired height. 4. Guardrails: Guardrails are essential safety accessories that can be attached to steel props to prevent falls from elevated platforms. They create a barrier around the working area, reducing the risk of accidents and providing a safe working environment. 5. Prop sleeves: These sleeves are used to protect the steel props from damage during transportation or storage. They are designed to fit snugly over the prop, preventing scratches, dents, or corrosion. 6. Prop pins and clips: These small accessories are used to secure the adjustable parts of the steel props in place. They prevent accidental movement or collapse, ensuring the structural integrity of the props. 7. Prop braces: Braces are used to provide additional support and stability to the steel props. They are commonly used in situations where the props need to withstand heavy loads or extreme conditions. 8. Prop storage racks: These racks are specifically designed to store steel props when they are not in use. They help organize and protect the props, making them easily accessible and prolonging their lifespan. These accessories not only enhance the performance and versatility of steel props but also contribute to the overall safety of construction sites. It is important to choose the appropriate accessories based on the specific requirements of the project and ensure they are properly installed and maintained.

- Q: Can steel props be reused?

- Steel props, commonly utilized in construction and renovation endeavors, serve as adjustable metal support devices. Their purpose is to offer temporary support to structures during these processes. These props are known for their durability and reliability and, with adequate upkeep, can be reused on multiple occasions. Once a construction project is finalized, the steel props can be disassembled, inspected, and, if deemed satisfactory, cleaned, repaired if necessary, and stored for future implementation. The decision to reuse steel props not only aids in waste reduction and cost savings but also guarantees the efficient and secure completion of construction projects. Nevertheless, it is imperative to emphasize the significance of conducting thorough inspections and maintenance to ensure the structural integrity and safety of the steel props prior to reutilizing them.

- Q: What are the common signs of wear or damage on steel props?

- The signs of wear or damage on steel props can vary depending on the type of prop and how it is used. However, there are some general indicators that can help detect potential issues: 1. Rust or corrosion: One common sign of wear on steel props is the presence of rust or corrosion. This can happen when the prop is exposed to moisture or chemicals, weakening the steel and compromising its load-bearing capacity. 2. Bent or twisted parts: Excessive loads or impacts can cause steel props to bend or twist. This affects the stability and strength of the prop, making it unsafe for further use. 3. Cracks or fractures: Another sign of wear or damage is the presence of cracks or fractures on the steel prop. These can be caused by fatigue or overloading, compromising the prop's structural integrity. 4. Loose or damaged fittings: Steel props often have various fittings, such as pins, bolts, or adjustable mechanisms, which can become loose or damaged over time. Regularly checking these fittings for signs of wear or damage is important to ensure proper functioning and stability. 5. Excessive wear on load-bearing surfaces: The baseplate or head plate of steel props, which bear the load, can show signs of excessive wear or deformation. This can be caused by repetitive use or improper maintenance. Any deformations or uneven surfaces can affect the prop's stability and safety. 6. Reduced load capacity: If a steel prop is no longer able to efficiently support the intended load, it may be a sign of wear or damage. This can be caused by any of the above issues or a combination of factors, and it indicates that the prop should be carefully inspected and possibly replaced. Regularly inspecting and maintaining steel props is crucial to detect and address signs of wear or damage. Following manufacturer guidelines and consulting professionals when necessary ensures the safe and efficient use of steel props in construction or support applications.

- Q: Can steel props be used in outdoor construction projects?

- Yes, steel props can be used in outdoor construction projects. Steel props are commonly used in construction to support temporary loads such as formwork, scaffolding, and shoring. They are designed to be versatile and durable, making them suitable for outdoor use. Steel props are typically made from high-quality steel and are designed to withstand heavy loads and adverse weather conditions. They have adjustable heights and can be easily set up and dismantled, making them convenient for outdoor projects. In outdoor construction projects, steel props can be used to support various structures like walls, slabs, beams, and columns. They provide stability and ensure the safety of the construction site. Additionally, steel props can be easily secured in the ground or on concrete slabs, providing a reliable support system for the construction activities. Furthermore, steel props are resistant to rust and corrosion, which is essential for outdoor use where they may be exposed to rain, sun, and other elements. This durability ensures that the steel props maintain their structural integrity throughout the construction project. In conclusion, steel props are an excellent choice for outdoor construction projects. They offer strength, versatility, and durability, making them suitable for supporting temporary loads in various outdoor construction activities.

- Q: Can steel props be used in tunnel repair projects?

- Yes, steel props can be used in tunnel repair projects. Steel props are commonly used in construction and engineering projects to provide temporary support to structures. In tunnel repair projects, steel props can be used to provide additional support to tunnel walls, ceilings, or floors that may have been damaged or weakened. These props help to distribute the load of the tunnel and prevent further collapse or damage. Additionally, steel props are adjustable and can be easily installed and removed, making them a convenient choice for tunnel repair projects.

- Q: Can steel props be used for supporting temporary event structures?

- Indeed, temporary event structures can indeed be supported by steel props. These adjustable and versatile support systems are frequently utilized in construction and temporary structures. They offer a robust and stable foundation, rendering them perfect for temporary event structures like stages, tents, and marquees. The height of steel props can be effortlessly modified to meet specific requirements, and they can be firmly secured in position to guarantee structural stability and safety. Moreover, steel props boast durability and the ability to withstand substantial loads, thereby making them well-suited for supporting temporary event structures.

Send your message to us

steel props of B

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords