steel props of lift

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

suspended slab formwork

slab form work

concrete slab formwork

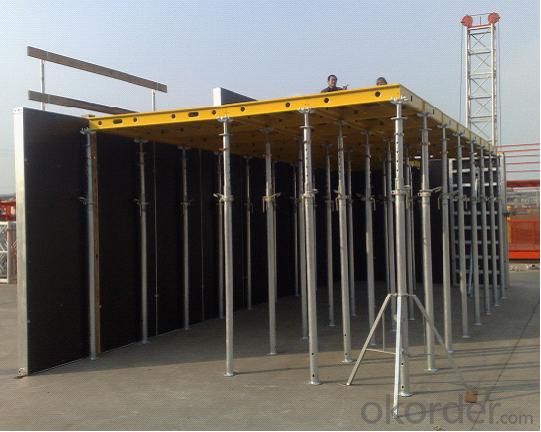

150 Aluminum Frame Early Dismantling Slab Formwork With Adjustable Prop

Description:

1. Brief introduction

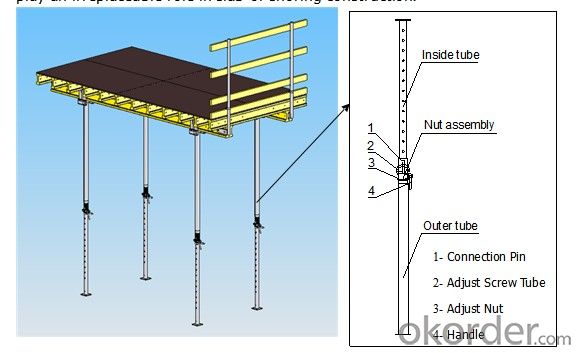

Especially for projects with a large number of similar applications and open facades, Alu-slab system is the right solution. The panel is end product, no assembling on site and it is easily to build, ease of application, more important thing is, the panel is light weight, a dead lift is achieved, save time and effort.

2. Competitive advantage

① Light weight but high load bearing capacity

The panels could be transported by manual work so that it greatly reduces the aggregate cost, accelerates the erection speed, and all in all increases the aggregate benefit.

②Quickly turnover of slab panels

The early dismantling prop system speed up the turnover of the panels, minimize the investment, lower the cost, improve the working efficiency, and shorten the project period under the precondition of keeping the concrete structure and safety uninfluenced, in line with the erection requirement and ensuring the project quality.

③Cost effective with early dismantling prop system.

This early dismantling system is simple, safe and fast, saving at least 50% percent of your construction time.

3. Applications

- Q: Are steel props adjustable in both height and width?

- Steel props are usually only adjustable in terms of height. Their primary function is to offer support and stability to structures during construction or renovation endeavors. These props are specifically designed to facilitate effortless height adjustments by extending or retracting the inner tube. Nevertheless, it is worth noting that the width of steel props is generally fixed and non-adjustable.

- Q: How do steel props contribute to the prevention of wall and floor cracks?

- Steel props contribute to the prevention of wall and floor cracks by providing structural support and stability during construction or renovation projects. They help distribute the weight load evenly, ensuring that walls and floors remain level and do not experience excessive movement or settling. This minimizes the risk of cracks forming due to uneven weight distribution or structural instability, ultimately preserving the integrity and longevity of the building.

- Q: Are steel props suitable for use in offshore wind farm construction?

- Yes, steel props are suitable for use in offshore wind farm construction. Steel props offer high strength and durability, making them ideal for withstanding the harsh offshore environment. They provide reliable support for various construction activities, such as installing foundations, assembling tower sections, and lifting heavy equipment. Additionally, steel props can be easily adjusted and secured in place, ensuring stability and safety during construction operations in offshore wind farms.

- Q: Can steel props be used in construction of hospitals?

- Yes, steel props can be used in the construction of hospitals. Steel props, also known as steel acrow props or steel support props, are adjustable steel columns that are commonly used in construction to provide temporary support to structures, such as walls, floors, and ceilings. These steel props are typically made of high-grade steel and are designed to withstand heavy loads, making them suitable for use in various construction projects, including hospitals. In the construction of hospitals, steel props can be used to support temporary structures, such as formwork for concrete walls or slabs, scaffolding for access to different levels, or to provide additional support during the installation of heavy equipment or machinery. They can also be used to reinforce existing structures during renovations or repairs. Steel props offer several advantages in construction, including their strength, durability, and adjustability. Their adjustable feature allows for easy customization to fit the specific height requirements of a hospital construction project. Additionally, steel props are known for their stability and load-bearing capacity, providing a safe and reliable support system during the construction process. It is important to note that while steel props can be used in the construction of hospitals, they are typically used as temporary support systems rather than permanent structural elements. Steel props are designed to be easily installed, adjusted, and removed, making them ideal for temporary applications in construction. Therefore, it is essential to consult with structural engineers and follow building codes and regulations to ensure the safe and proper use of steel props in hospital construction projects.

- Q: What are the common certifications and standards for steel props?

- Steel props used in the construction industry are subject to several certifications and standards, including the British Standard (BS) 4074, the European Standard (EN) 1065, and the American National Standards Institute (ANSI) A10.9. The widely recognized British Standard BS 4074 certifies adjustable steel props used in temporary support systems. It establishes requirements for the design, materials, and performance of these props to ensure their safety and reliability. BS 4074 covers various aspects, such as load-bearing capacity, adjustable height range, and structural stability. Similarly, the European Standard EN 1065 provides guidelines for the design and testing of adjustable steel props used in construction. It specifies requirements for materials, dimensions, mechanical performance, and marking. This standard ensures that the props conform to European safety standards. In the United States, the primary standard for steel props is the American National Standards Institute (ANSI) A10.9. It sets safety requirements for shoring and scaffolding systems, including adjustable steel props. ANSI A10.9 covers aspects such as design, manufacturing, testing, and inspection of props, ensuring compliance with safety regulations. Additionally, there may be region or country-specific certifications and standards. For example, the National Association of Steel-framed Housing (NASH) in Australia provides guidelines for steel props used in residential construction. Overall, these certifications and standards are crucial for maintaining the quality, reliability, and safety of steel props in construction projects. Compliance with these standards enables builders, contractors, and workers to select and use props that meet the necessary safety requirements, minimizing the risk of accidents or structural failures.

- Q: Can steel props be used for supporting retaining walls?

- Yes, steel props can be used for supporting retaining walls. Steel props offer high load-bearing capacity and stability, making them suitable for providing temporary or permanent support to retaining walls. They can effectively withstand the pressure exerted by the soil and ensure the stability and integrity of the walls.

- Q: Can steel props be used in the construction of wastewater treatment plants?

- Steel props are indeed capable of being utilized in the construction of wastewater treatment plants. In construction projects, steel props are commonly employed to offer support to structures and provide temporary assistance throughout the construction process. When it comes to wastewater treatment plants, steel props can fulfill the role of supporting a range of components such as tanks, pipelines, and equipment during the installation phase. They ensure stability and structural reinforcement, guaranteeing that the components remain securely in position. Additionally, steel props can also be utilized to support temporary structures like scaffolding, enabling workers to safely access different areas of the treatment plant during construction or maintenance tasks. All in all, steel props present a versatile and dependable alternative for supporting the various elements involved in wastewater treatment plant construction.

- Q: Are steel props suitable for supporting temporary scaffolding towers?

- Yes, steel props are suitable for supporting temporary scaffolding towers. Steel props provide excellent strength and stability, making them ideal for supporting the weight and structure of scaffolding towers. Their adjustable height feature also allows for easy customization and adaptation to different construction requirements.

- Q: The bracing of deep foundation pit, in case of multi support, support between the layout of what Laiding?

- Deep foundation pit support is the Ministry of housing and urban and rural construction of the "greater risk of sub sub project safety management approach" to build quality [2009]87 content,

- Q: Are steel props suitable for supporting temporary signage or billboards?

- Yes, steel props are suitable for supporting temporary signage or billboards. Steel props are commonly used in construction and are designed to provide sturdy support for various structures. They are made from high-quality steel, which makes them strong and durable. Steel props can be easily adjusted to the desired height and are capable of supporting heavy loads. Additionally, they have a wide base and offer stability, which is crucial for supporting temporary signage or billboards, especially in outdoor environments where wind and other weather conditions may pose a challenge. Overall, steel props are a reliable and effective choice for supporting temporary signage or billboards.

Send your message to us

steel props of lift

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords