Steel Plastic Geogrids Prices in Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

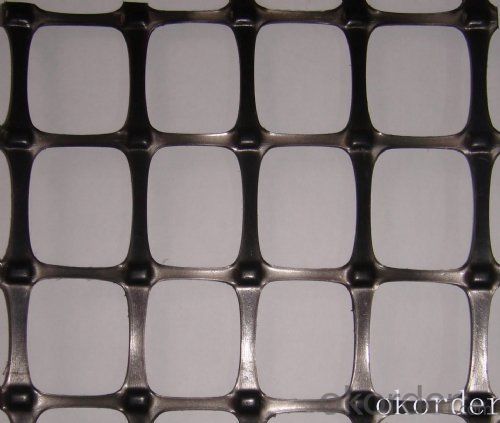

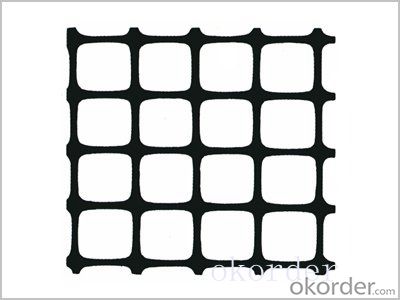

The Steel plastic composite geogrid is by the high tensile steel wire, after the special handing, with the polyethylene(P. E), and increase other assistants, though squeezes out causes it excel to become the mult-skill anti-to pull the banding, and the surface has the rough embossing, for excel in reinforcement earthwork belt. From this as soon as the single belt, after vertical, according to decides the spacing knitting horizontally or clamps gathers the arrangement, uses the ultrasonic welding to molding.

The Steel plastic composite geogrid is by the high tensile steel wire, after the special handing, with the polyethylene(P. E), and increase other assistants, though squeezes out causes it excel to become the mult-skill anti-to pull the banding, and the surface has the rough embossing, for excel in reinforcement earthwork belt. From this as soon as the single belt, after vertical, according to decides the spacing knitting horizontally or clamps gathers the arrangement, uses the ultrasonic welding to molding.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles help with slope stabilization?

- Geotextiles help with slope stabilization by providing erosion control, reinforcement, and drainage. They act as a barrier to prevent soil erosion, retain soil particles, and allow water to drain through the fabric, reducing the buildup of excess water pressure. Additionally, geotextiles enhance the stability and strength of slopes by distributing loads and limiting soil movement, thus preventing landslides and slope failures.

- Q: How do geotextiles help in preventing soil erosion on slopes?

- Geotextiles act as a barrier between soil and water, allowing for better drainage and filtration. They stabilize the soil, prevent particle movement, and reduce surface erosion by increasing the overall shear strength of the slope.

- Q: Can the tunnel longitudinal drains be wrapped with geotextiles and wrapped with a waterproof board?

- With geotextile wrapped drainage pipe is generally played the role of seepage drainage, do not need waterproof board (you said the waterproof board should be geomembrane it) Chong Hong geotextile material manufacturers

- Q: How do geotextiles help in preventing the loss of aggregate in unpaved roads?

- Geotextiles are used in unpaved roads to prevent the loss of aggregate by providing stabilization and reinforcement. When placed between the soil and aggregate layers, geotextiles act as a barrier that allows water to pass through while retaining the aggregate, effectively preventing erosion and maintaining the road's integrity.

- Q: Are geotextiles resistant to fire?

- Yes, geotextiles are generally resistant to fire. They are typically made from materials that have high melting points and are designed to withstand exposure to heat and flames without catching fire or spreading flames. However, it is important to note that the level of resistance may vary depending on the specific type and composition of the geotextile.

- Q: Composite geotextile have what model specifications

- Composite geomembrane; mass per unit area g / m000 Membrane thickness mm0.25-0.350.3-0.5 breaking strength KN / m57.510.012.014.016.018.0 vertical and horizontal elongation at break% 30-100CBR breaking strength KN ≥ 1.11 . 51.92.22.52.83.0 Tearing strength KN≥0.150.250.320.40.480.560.62 Vertical and horizontal peel strength N / cm6 Vertical and horizontal permeability coefficient cm / sk * 10-11-10-13k = 1.0-9.9

- Q: Welding geotextile how to apply the mattress on or below

- Geotextile does not need welding, geotextile is geotextile, the product itself exists gaps and pores, in the project mainly play a filter, filter, reinforcement, the role of protection, can not achieve the role of anti-seepage. Generally only need to suture on it. Composite geotextile need to be welded, composite geotextile, also known as composite geomembrane, by the geomembrane through a series of production processes, the upper and lower sides were combined on the geotextile production. In the production process in each roll of composite geotextile of the four sides will be set aside 10-20cm width of the welding edge. Welding construction only need to weld the edge of the geomembrane welding, welding edge of the geotextile suture can be. Geomembrane need to be welded, geomembrane is divided into smooth geomembrane and rough geomembrane (matte geomembrane), smooth geomembrane without the need for direct laying of welding on it. Rough surface geomembrane is generally covered with wool up, welding need to remove the surface and then welding.

- Q: How are geotextiles tested for strength and durability?

- Geotextiles are tested for strength and durability through various methods such as tensile strength tests, puncture resistance tests, tear strength tests, and abrasion resistance tests. These tests involve subjecting the geotextile to controlled forces and conditions to determine its ability to withstand different types of stresses and strains. Additionally, long-term exposure tests are conducted to assess the geotextile's durability under simulated environmental conditions, ensuring its performance over time.

- Q: Such as title. The manager asked them to be made into a square meter compound. What materials can be used to bind them live. 502 glue can not be filled Cao Cao 丨 not only check the intestine Lu adhesive can not be used, glue rods can be used, but EVA is transparent after the appearance of poor adhesion. Neighborhoods. More

- With AB glue it

- Q: Are geotextiles resistant to rodent damage?

- Geotextiles are generally not resistant to rodent damage.

Send your message to us

Steel Plastic Geogrids Prices in Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords