Steel Flat Bar ISO and SGS Certificate Cold Rolled Flat Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Advantage of Steel Flat Bar ISO and SGS Certificate Cold Rolled Flat Bars

1.Prime quality

2.Competitive price

3.Professional service

4.Prompt delivery & Seaworthy packing

5.Mill Test Certificate

Specification of Steel Flat Bar ISO and SGS Certificate Cold Rolled Flat Bars

Material: Q235; A36; SS400; ST37; SAE1006/1008; S275JR; Q345,S355JR; 16Mn; ST52 etc.

thickness: 3-30mm, width 10-400mm, length 5-12M

Length: fixed length, random length

Application of Steel Flat Bar ISO and SGS Certificate Cold Rolled Flat Bars

Household Appliance | Refrigerator shutter &side panels, Rice Cooker, Washer, Microwave Ovens, Freezers, Air conditions, Water Heaters, Sterilization Cabinets, Range Hoods, Computer Panels , DVD/DVB panels, TV back panel etc. |

Construction Material | Fireproof Door &Kitchen Cabinet ,Ceiling, Sanitary Unit, Elevator etc. |

Transportation | Car, Ship, Trains, Aircraft Equipment. etc. |

Education and Health Field | Electronic Writing Boards, Projection Screens, Clean Operating Rooms, etc. |

A)Features of Stainless Steel Flat Bar:

a) The appearance of cold-rolled products gloss is good, beautiful;

b) Excellent high temperature strength;

c) Excellent work-hardening (after processing weakly magnetic)

d) Non-magnetic state solution.

B)Specifications of Stainless Steel Flat Bar:

1. Standard: GB ASTM, JIS, etc.

2. Grade: 200,300,400series

3. Size: 3mm*19mm ~ 12mm*140mm

4. Thickness: from 3mm to 12mm

5. Width: from 19mm to 140mm

6. Shape Manufactured: flat bar

7. Length: 2-6m or as customers' request

8. Surface finish: Black & Pickled & Bright

9. Manufacture technology: cold drawn/cold rolled/hot rolled

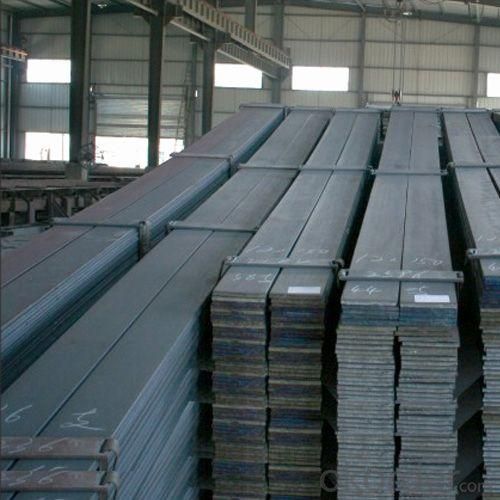

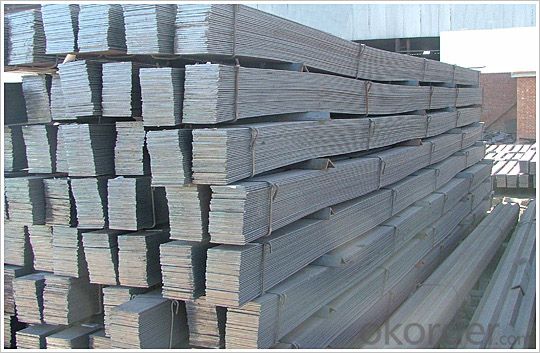

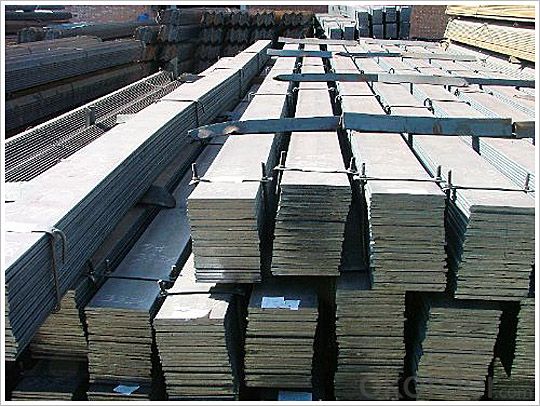

C) Product Photos

- Q: Are steel flat bars suitable for making architectural elements?

- Yes, steel flat bars are suitable for making architectural elements. They are versatile, durable, and can be easily shaped and manipulated to create various architectural designs and structures. Additionally, steel flat bars offer high strength and stability, making them an ideal choice for supporting heavy loads and providing structural integrity in architectural projects.

- Q: Are steel flat bars suitable for making gears or sprockets?

- Steel flat bars are indeed suitable for making gears or sprockets, especially if they are made from high-quality steel. Steel is known for its strength, durability, and resistance to wear and tear, making it an excellent material for gears and sprockets that need to withstand heavy loads and repetitive motion. Additionally, steel can be easily machined and shaped into the desired gear or sprocket profiles, making it a versatile choice for such applications. However, it is important to note that the specific requirements of the gears or sprockets, such as size, tooth profile, and surface finish, should be taken into consideration when selecting the appropriate steel flat bar for the job.

- Q: What is the tolerance for thickness in steel flat bars?

- The tolerance for thickness in steel flat bars can vary depending on industry standards and requirements specific to each sector. Typically, the tolerance for thickness in steel flat bars is specified as a plus or minus value. For instance, a common tolerance for thickness in steel flat bars may be +/- 0.005 inches. This indicates that the actual thickness of the steel flat bar can deviate by up to 0.005 inches in either direction from the specified thickness. However, it is important to highlight that the tolerance for thickness may differ depending on the grade, type, and application of the steel flat bars. Therefore, it is crucial to refer to the manufacturer's guidelines and industry standards to determine the precise tolerance for thickness in steel flat bars for a specific application.

- Q: Are steel flat bars suitable for creating industrial equipment or machinery?

- Yes, steel flat bars are suitable for creating industrial equipment or machinery. They offer excellent strength and durability, making them ideal for constructing various components and structures in the industrial sector. Steel flat bars can be easily fabricated, welded, and machined to meet specific requirements, ensuring the quality and reliability of the equipment or machinery being produced.

- Q: Are steel flat bars suitable for load-bearing structures in bridges?

- Steel flat bars are well-suited for load-bearing structures in bridges. Due to their superior strength and durability, they are frequently employed in bridge construction. Their ability to endure heavy loads and offer exceptional structural support is noteworthy. Moreover, steel flat bars can be effortlessly welded or bolted together, facilitating efficient construction and convenient customization to meet precise bridge design needs. Additionally, these bars display resistance to corrosion, a vital attribute for bridge structures exposed to outdoor elements. All in all, steel flat bars are a dependable and economical option for load-bearing structures in bridges.

- Q: How do you protect steel flat bars from rusting?

- To protect steel flat bars from rusting, a common method is to apply a protective coating such as paint, varnish, or a rust-resistant primer. Additionally, using a corrosion inhibitor or regularly applying a rust-preventive oil can help safeguard the steel from moisture and oxidation. It's also important to keep the flat bars stored in a dry and well-ventilated area to minimize exposure to moisture.

- Q: What are the different methods of surface texturing for steel flat bars?

- Steel flat bars can be textured using various methods, each with its own benefits and applications. These methods allow for the creation of different textures and patterns on the bars, enhancing their appearance, grip, or functionality. Common techniques for surface texturing of steel flat bars include: 1. Shot blasting: By propelling small metal or abrasive particles onto the bars at high speeds, this method removes scale, mill scale, or rust, resulting in a clean and rough finish. 2. Sanding or grinding: Using abrasive tools like sandpaper or grinding wheels, material is manually removed from the bars' surface, creating textured finishes with patterns or grooves. 3. Knurling: This process involves rolling or pressing ridges or grooves onto the bars' surface, improving grip and preventing slipping, making it suitable for non-slip applications. 4. Acid etching: Chemical solutions selectively remove a thin layer of the steel's surface, creating precise and intricate textured patterns, including designs or logos. 5. Roller embossing: Bars are passed through rollers with engraved patterns, pressing the pattern onto the surface and creating various designs and textures for aesthetic appeal. 6. Laser texturing: Laser technology removes material from the surface, achieving precise and intricate patterns with high accuracy and repeatability. This method is ideal for decorative purposes or specialized applications that require precise texture control. Each method has its advantages and should be chosen based on the desired texture, application requirements, and cost-effectiveness. Selection depends on factors like intended use, desired appearance, functionality, and budget constraints.

- Q: What is the yield strength of a steel flat bar?

- The yield strength of a steel flat bar is the amount of stress or force it can bear before it permanently deforms. It is a significant mechanical property that indicates the maximum load the steel can handle without experiencing plastic deformation. The yield strength of a steel flat bar may differ based on the grade and type of steel used. Typically, common grades of steel used in flat bars have yield strengths ranging from 36,000 to 80,000 pounds per square inch (psi) or 250 to 550 megapascals (MPa). However, it's crucial to note that these values can vary and may depend on factors like the manufacturing process and any additional treatments or alloys used in the steel. Therefore, it is essential to refer to the specific specifications or testing data provided by the manufacturer or supplier to accurately determine the yield strength of a specific steel flat bar.

- Q: What are the standard tolerances for straightness in steel flat bars?

- The standard tolerances for straightness in steel flat bars vary depending on the specific industry and application. However, in general, the common tolerance range for straightness in steel flat bars is typically within 0.25% to 0.5% of the total length of the bar.

- Q: How do steel flat bars contribute to the overall sustainability of infrastructure projects?

- Steel flat bars contribute to the overall sustainability of infrastructure projects in several ways. Firstly, they are durable and long-lasting, which means they require minimal maintenance and replacement over time, reducing the need for additional resources. Secondly, steel is a highly recyclable material, so at the end of its lifespan, flat bars can be recycled and reused in other projects, reducing waste and conserving natural resources. Additionally, steel flat bars have a high strength-to-weight ratio, meaning they can support heavy loads while requiring less material, which helps to reduce the overall carbon footprint of infrastructure projects.

Send your message to us

Steel Flat Bar ISO and SGS Certificate Cold Rolled Flat Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords