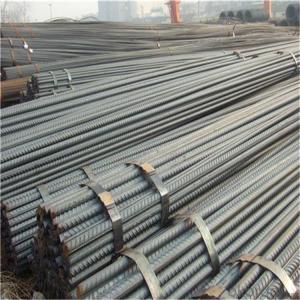

Steel Cold Rolled Deformed Bar For Container

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

Specifications of Steel Cold Rolled Deformed Bar For Container

Standard | GB | HRB400 | |

Diameter | 6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm, 22mm,25mm,28mm,32mm,36mm,40mm,50mm | ||

Length | 6M, 9M,12M or as required | ||

Place of origin | Hebei, China mainland | ||

Advantages | exact size, regular package, chemical and mechanical properties are stable. | ||

Type | Hot rolled deformed steel bar | ||

Chemical Composition of Steel Cold Rolled Deformed Bar For Container

Grade | Technical data of the original chemical composition (%) | ||||||

C | Mn | Si | S | P | V | ||

HRB400 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physical capability | |||||||

Yield Strength (N/cm²) | Tensile Strength (N/cm²) | Elongation (%) | |||||

≥400 | ≥570 | ≥14 | |||||

Usage and Applications of Steel Cold Rolled Deformed Bar For Container

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Packaging & Delivery of Steel Cold Rolled Deformed Bar For Container

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment term: TT or L/C

Delivery Detail: within 45 days after received advanced payment or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard Deformed Steel Bar we can supply:

Grade: GR40/GR60, G460B/B500A/B500B/B500C,BST500S

Standard: ASTM, BS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply Deformed Steel Bar; if you need anything about building materials, please contact us for further information.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

- Q: What is the effect of exposure to chemicals on steel rebars?

- Exposure to chemicals can have various effects on steel rebars depending on the specific chemical involved. Corrosive chemicals, such as acids or salts, can cause corrosion and weaken the steel rebars over time. This can compromise the structural integrity of reinforced concrete structures, leading to potential safety hazards. On the other hand, some chemicals like epoxy or protective coatings can be applied to steel rebars to enhance their resistance to corrosion and extend their lifespan. Overall, the effect of exposure to chemicals on steel rebars can range from degradation to protection, highlighting the importance of proper material selection and maintenance in construction projects.

- Q: What is the role of steel rebars in preventing concrete spalling due to fire?

- Steel rebars play a crucial role in preventing concrete spalling due to fire by providing reinforcement and structural integrity to the concrete. When exposed to high temperatures during a fire, concrete can undergo thermal expansion, which can lead to cracking and spalling. However, the presence of steel rebars helps to restrain the expansion and prevent the concrete from breaking apart. The rebars act as a reinforcement, distributing the stresses caused by the heat and preventing the concrete from failing under the extreme conditions. Overall, steel rebars enhance the fire resistance of concrete structures and help maintain their structural integrity during a fire event.

- Q: What are the different types of steel rebars used in airport construction?

- In airport construction, various types of steel rebars are employed to ensure the structural integrity and durability of the infrastructure. Some of the commonly used types of steel rebars in airport construction include: 1. Mild Steel Rebars: These rebars are the most basic and commonly used type of reinforcement in airport construction. They are made of carbon steel and have a smooth surface. Mild steel rebars provide general reinforcement and are suitable for various applications in airport runways, taxiways, and aprons. 2. High Strength Deformed (HSD) Steel Rebars: HSD rebars are treated with heat during the manufacturing process, resulting in enhanced strength and ductility. These rebars have ribbed surfaces that provide better adhesion to concrete, making them ideal for critical structural elements in airport construction, such as beams, columns, and foundations. 3. Epoxy-Coated Rebars: In environments where corrosion is a concern, epoxy-coated rebars are used. These rebars have a protective coating of epoxy resin that prevents the steel from coming into direct contact with moisture and chemicals present in concrete. Epoxy-coated rebars are commonly used in airport construction projects, especially in areas exposed to de-icing salts and other corrosive substances. 4. Stainless Steel Rebars: Stainless steel rebars offer excellent corrosion resistance and are commonly used in coastal airport locations or areas with high humidity. They are particularly suitable for reinforcing concrete structures in airport terminals, hangars, and other areas where aesthetics and durability are crucial. 5. Galvanized Rebars: Galvanization involves coating the steel rebar with a layer of zinc to provide protection against corrosion. Galvanized rebars are commonly used in areas with high moisture content or where the concrete is exposed to harsh weather conditions. They are commonly employed in airport construction projects for reinforcing structures like retaining walls, drainage systems, and other external components. 6. Welded Wire Fabric (WWF): Welded wire fabric consists of a series of parallel and perpendicular steel wires welded together to form a mesh-like structure. This type of rebar is used in airport construction for concrete slabs, pavements, and other large surface areas. WWF provides uniform reinforcement and helps distribute loads evenly across the structure. It's important to note that the choice of steel rebars in airport construction depends on factors such as the specific application, structural requirements, environmental conditions, and local building codes. Consulting with structural engineers and construction professionals is crucial to determine the most appropriate type of steel rebar for each specific application in airport construction projects.

- Q: Are there any health and safety concerns related to steel rebars?

- Yes, there are several health and safety concerns related to steel rebars. Firstly, handling and lifting steel rebars can pose risks of musculoskeletal injuries such as strains, sprains, and back injuries. These rebars are heavy and often require manual handling or the use of heavy machinery, which can increase the risk of accidents and injuries. Secondly, steel rebars are often coated with chemicals to prevent corrosion. These coatings can contain hazardous substances such as toxic metals or volatile organic compounds (VOCs). Exposure to these chemicals through inhaling fumes or direct contact with the skin can lead to health issues, including respiratory problems, skin irritation, and chemical burns. Furthermore, steel rebars are commonly used in construction sites, which can be hazardous environments. Workers may face risks of falling rebars, tripping over them, or being struck by them. Additionally, improper installation or positioning of steel rebars can compromise the structural integrity of the construction, potentially leading to accidents or collapses. To mitigate these health and safety concerns, it is important to provide appropriate training and personal protective equipment (PPE) to workers handling steel rebars. Employers should also enforce proper lifting techniques and safe work practices to prevent musculoskeletal injuries. Adequate ventilation systems and the use of respiratory protection can help in reducing exposure to hazardous chemicals. Lastly, regular inspections and adherence to construction regulations can ensure the proper placement and installation of steel rebars, minimizing the risk of accidents and structural failures.

- Q: How do steel rebars affect the overall safety of construction projects?

- The overall safety of construction projects is greatly enhanced by steel rebars, which play a crucial role. One of the main benefits of steel rebars is their ability to reinforce concrete structures, making them stronger and more resistant to different types of forces like tension, compression, and bending. This reinforcement significantly improves the structural integrity of buildings, bridges, and other constructions, thereby reducing the risk of collapse or failure. In addition to their reinforcing properties, steel rebars also possess excellent ductility, meaning they can deform without breaking under extreme loads. This characteristic allows rebars to absorb and distribute the energy produced during earthquakes, high winds, or heavy impacts, thereby preventing sudden and catastrophic structural failures. Moreover, steel rebars can withstand high temperatures and fire, ensuring that they retain their strength and integrity in the event of a fire, which is crucial for the safety of occupants. Furthermore, steel rebars are highly resistant to corrosion, a common issue in construction projects. Corrosion gradually weakens the structure by deteriorating the reinforcement over time. However, using steel rebars significantly reduces the risk of corrosion, thus extending the lifespan of the construction and ensuring its long-term safety. Overall, the use of steel rebars in construction projects is essential for guaranteeing the safety and durability of structures. They enhance the strength, stability, and resistance of the building, enabling it to withstand various external forces and potential hazards. By incorporating steel rebars into construction designs, engineers and builders can ensure that the finished project meets the required safety standards, providing assurance for both construction industry professionals and the public.

- Q: What are the different shapes and profiles of steel rebars?

- Steel rebars are available in various shapes and profiles, including round, square, and deformed. Round rebars have a circular cross-section and are commonly used in general construction projects. Square rebars have a square cross-section and are often used for specific applications that require additional strength and stability. Deformed rebars have ridges or deformations on their surface, which provide enhanced bonding with concrete and are commonly used in reinforced concrete structures to improve load-bearing capacity and prevent slippage.

- Q: Can steel rebars be welded to other steel components?

- Steel rebars have the capability to be welded to other steel components. In construction projects, welding serves as a common method for connecting steel rebars to various steel structures or components. This procedure involves heating the rebars and steel components to a high temperature, causing them to melt. Following this, they are allowed to cool and solidify, resulting in a strong and durable bond. Welding steel rebars to other steel components is widely accepted and contributes to the overall integrity and stability of the construction. By ensuring a dependable connection, it enables the rebars and steel components to effectively withstand external forces and loads. However, it is crucial to employ proper welding techniques and adhere to relevant industry standards and guidelines to guarantee a successful and safe welding process.

- Q: Can steel rebars be used in residential construction projects?

- Yes, steel rebars can be used in residential construction projects. They are commonly used to reinforce concrete structures such as foundations, walls, and columns in residential buildings to enhance their strength and durability.

- Q: What are the guidelines for ensuring proper bond between steel rebars and concrete?

- The guidelines for ensuring proper bond between steel rebars and concrete are crucial to ensure the structural integrity and performance of reinforced concrete structures. Here are some key guidelines to follow: 1. Proper Bar Placement: The rebars should be positioned within the concrete member as per the design specifications, including the required spacing, cover, and lap lengths. The spacing between rebars and the concrete surface should be maintained to provide enough concrete cover and prevent corrosion. 2. Adequate Surface Preparation: The steel rebars should be free from any loose rust, scale, or contaminants that could hinder the bond with the concrete. Surface preparation techniques such as wire brushing, sandblasting, or using a high-pressure water jet can be employed to clean the rebars effectively. 3. Mechanical Bond: Ribbed or deformed rebars offer better mechanical bond with concrete compared to smooth bars. The surface deformations increase the contact area between the rebar and the concrete, enhancing the bond strength. 4. Proper Embedment Length: The embedment length, also known as the development length, is the distance over which the rebar is embedded in the concrete. It is typically calculated based on the required bond strength, concrete strength, and rebar diameter. Adequate embedment length is crucial to achieve the desired bond performance. 5. Concrete Quality: The quality of concrete, including its strength, workability, and curing, plays a significant role in achieving a proper bond with steel rebars. The concrete mix should be proportioned correctly, ensuring adequate cement content, appropriate water-to-cement ratio, and proper compaction during placement. 6. Adequate Concrete Cover: Sufficient concrete cover should be provided around the rebars to protect them from environmental factors, prevent corrosion, and ensure long-term durability. The concrete cover is typically specified in design codes and should be maintained during construction. 7. Proper Reinforcement Splicing: When multiple rebars need to be connected, proper splicing techniques should be employed to ensure a continuous and strong bond. Lap splices, mechanical couplers, or welded splices can be used depending on the design requirements and project specifications. 8. Effective Vibrations: During concrete placement, proper vibration techniques should be employed to ensure adequate compaction and minimize voids or honeycombs around the rebars. This helps to achieve a better bond between the steel rebars and the surrounding concrete. 9. Avoidance of Contamination: The rebars should be protected from contamination during storage and construction. Exposure to excessive moisture, chemicals, or other corrosive substances can compromise the bond between the rebars and the concrete. 10. Adherence to Design Specifications: Finally, it is crucial to strictly adhere to the design specifications and recommendations provided by structural engineers or relevant design codes. These guidelines are tailored to ensure a proper bond between steel rebars and concrete, taking into account various factors such as loadings, environmental conditions, and durability requirements.

- Q: How do steel rebars affect the overall load-bearing capacity of a structure?

- Steel rebars significantly enhance the load-bearing capacity of a structure by reinforcing the concrete and enhancing its tensile strength. The addition of steel rebars improves the structural integrity, increases resistance to bending and cracking, and allows the structure to withstand heavier loads and external forces.

Send your message to us

Steel Cold Rolled Deformed Bar For Container

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords