steel coil, prepainted steel coil,prepainted galvanized steel coil 9 J

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | DX51D,SGCC,SGCH,Q195,END10142,ASTM A653 | Thickness: | 0.18-0.80mm |

| Place of Origin: | Shandong China (Mainland) | Brand Name: | cnbm | Model Number: | prepainted galvanized steel coil |

| Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | Coated |

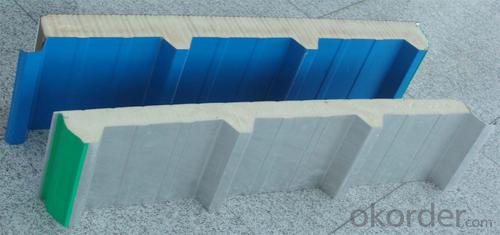

| Application: | Roof,Sandwich panel,or other | Special Use: | High-strength Steel Plate | Width: | 1250mm or under |

| Length: | Coil or Sheet | surface:: | Color Steel | Name :: | prepainted galvanized steel coil |

| Coil weight :: | 4-10 tons | Finish paint:: | 12um(polyest paint)or according to order | primer paint:: | 5um(polyurethane paint)or according to order |

| zinc coating weight: | 40-180g/m2 |

Packaging & Delivery

| Packaging Detail: | 1. prepainted galvanized steel coil :Seaworthy standard export package 2.prepainted galvanized steel coil :as your requirement |

| Delivery Detail: | 7-30days after receiving deposit |

Specifications

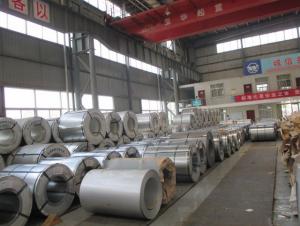

steel coil, prepainted steel coil,prepainted galvanized steel coil

1.prepainted galvanized steel coil

2.width:600-1250mm

steel coil, prepainted steel coil,prepainted galvanized steel coil

1. steel coil, prepainted steel coil,prepainted galvanized steel coil

Advantages:

(1).High strength, Good corrosion

(2).Well rainproof performance

(3). Easy to install and remove

(4).Competitive price with best quality

2. About our company :

Jinan Wobund Energy Technology Co., Ltd. is a professional manufacturing and trading company of steel coils. Our main products includePPGI prepainted galvanized steel coil , galvanized steel coil Color coated steel coil. Meanwhile, based on the geographical and industrial advantages, we are also engaged in some other products, such as color coated steel tiles, polystyrene foam plates, color printed steel plates, heat-insulated steel sandwich plates, plastic steel composite panels and color profiled steel plates.

3.Describe of steel coil, prepainted steel coil,prepainted galvanized steel coil

1). prepainted galvanized steel coil usually refers to have substrate processed with surface processed and coated then(roller coated )or bonded organic thin film and baked, and it is able to be processed to final prodevtion

2). prepainted galvanized steel coil qualified with excellent decorative ,formability ,corrosion resistance ,coating adhesion ,can keep for a long time as well as maintain fresh color .For color coated steel sheet can obtain good economic benefit by steel belt wood ,efficient in construction and save energy ,prevent pollution etc.Which is an ideal material;for manufacturing board.

4. steel coil, prepainted steel coil,prepainted galvanized steel coil data:

These specifications of PPGI are for your referance :

Product | PPGI/PPGL | Galvanized | Galvalume/Aluzinc | |

Certificate | ISO9001:2008,ISO14001:2004 | |||

standard | ASTM A755 | ASTM A653 | ASTM A792 | |

Grade | CGCC/CGLCC | SGCC/CS/DX51D | SGLCC/CS/DX51D | |

Model | Thick:0.16-0.90mm | Thick:0.14-3.5mm | Thick:0.23-2.0mm | |

Type | Roll/Coil | Roll/Coil | Roll/Coil | |

surface | Protective | Chromating Treatment Oiled | ||

Application | Structural,Roofing,Commercial use,Household Appliance,Industry | |||

Special | Wear resistant steel,High-strength-steel plate | |||

5. Our service:

1). All of our products are with professional service .

2). Competitive price, competitive shipments and efficient oversea service.

3). Rich technical professionals can supply buyer with wide range technical support.

- Q: What are the different types of edge treatments for steel coils?

- Steel coils can undergo different edge treatments, each serving a specific purpose and offering unique benefits. 1. The most commonly used edge treatment is the slit edge. This involves cutting the coil along its width, resulting in two distinct edges. Slit edges are usually smooth and free from burrs, making them suitable for most applications. 2. The mill edge is the untreated edge of a steel coil straight from the rolling mill. It has a rough and uneven surface with visible imperfections like burrs and irregularities. Mill edges are generally not suitable for direct use and require further processing or trimming to achieve the desired edge quality. 3. The trimmed edge is a treatment that involves removing the rough and irregular portions of the mill edge. This is done through shearing or cutting, resulting in a smoother and more consistent edge. Trimmed edges are commonly used when a clean and uniform appearance is required. 4. Deburred edge refers to the process of removing any sharp or rough edges from the steel coil. This treatment is crucial for applications where safety is a concern as it eliminates the risk of injuries from handling sharp edges. Deburred edges are achieved through grinding or filing and provide a smooth and safe edge for various applications. 5. Rounded edge is a treatment that involves rounding the sharp corners of the steel coil. This is done to prevent damage to other materials or surfaces during handling or transportation. Rounded edges reduce the risk of scratches, dents, or other forms of surface damage. 6. Beveled edge is a treatment where the edge of the steel coil is cut at an angle, typically 45 degrees. This treatment is commonly used in applications that require a tight fit or seamless joint with other components. Beveled edges allow for easier assembly and improve the overall appearance of the final product. Each of these edge treatments offers its own advantages and is chosen based on the specific requirements of the application. Choosing the right edge treatment for steel coils is crucial to ensure optimal performance, safety, and aesthetics in industries such as construction, manufacturing, automotive, and more.

- Q: What are the main factors that affect the corrosion resistance of steel coils?

- The main factors that affect the corrosion resistance of steel coils include the composition and purity of the steel, the presence of alloying elements, the surface condition and finish of the coils, the exposure to moisture and corrosive substances, and the protective coatings or treatments applied to the steel.

- Q: this is for a school project due morrow can u please answerwhat are disadvantages of stainless steelplease also show were u got info ty

- Disadvantages of Stainless Steel: 1. High initial cost 2. Difficult to fabricate, or in other words, it is not as malleable as other metals, say iron, and hence if not fabricated properly, results in costly re-work. 3. Difficult to weld 4. High cost of polishing etc. i.e. adding finishing touches for the market. Also, for the record: Stainless steel does NOT rust. One of the advantages of it over other metals (steel and iron) are that it is rust-free. But of course, depending on the environment condition (E.g. long periods in a rainforest without use at all) it can rust....this is a very rare (and unfortunate) situation. ;)

- Q: Which type is better and give reasons why... I making a team of either Dark or Steel :D Thankyou

- This Site Might Help You. RE: Steel vs. Dark Pokemon? Which type is better and give reasons why... I making a team of either Dark or Steel :D Thankyou

- Q: How are steel coils shaped into specific forms?

- Steel coils are shaped into specific forms through a process known as roll forming. This involves passing the coil through a series of rollers that gradually bend and shape the steel into the desired form.

- Q: How are defects in steel coils detected and resolved?

- Defects in steel coils are detected through various methods such as visual inspection, ultrasonic testing, magnetic particle inspection, and eddy current testing. Once a defect is identified, it is resolved through processes like grinding, welding, or cutting out the affected area. In some cases, the entire coil may need to be rejected or sent for further processing to eliminate the defect.

- Q: What are the different types of steel coil finishes for aesthetics?

- There are several different types of steel coil finishes that are used for aesthetics, each offering a unique appearance and texture to the steel surface. Some of the most common types of finishes include: 1. Matte finish: This is a low-gloss finish that provides a smooth, non-reflective surface. It offers a clean and modern look to the steel coil, making it suitable for various applications in architectural and interior designs. 2. Brushed finish: Also known as satin finish, this type of finish is achieved by brushing the steel surface with a fine abrasive material. It creates a subtle, directional grain pattern on the surface, giving it a textured appearance. Brushed finishes are often used in kitchen appliances, decorative elements, and furniture. 3. Mirror finish: As the name suggests, this finish creates a highly reflective surface that resembles a mirror. It is achieved by polishing the steel surface to a high shine using abrasive materials. Mirror finishes are commonly used in architectural applications, such as decorative panels, elevator doors, and signage. 4. Patterned finish: This type of finish involves embossing or etching a pattern onto the steel surface. It can range from simple geometric designs to intricate textures, offering a unique and visually appealing look. Patterned finishes are widely used in interior design, automotive trims, and decorative panels. 5. Textured finish: Textured finishes are created by applying a texture to the steel surface, such as a stucco or diamond pattern. This adds depth and visual interest to the coil, making it suitable for various applications, including wall cladding, roofing, and garage doors. 6. Colored finish: In addition to different surface textures, steel coils can also be finished with various colors. This is achieved through the application of a coating or paint system, which not only enhances the aesthetic appeal but also provides protection against corrosion. Colored finishes are commonly used in architectural applications, such as building facades, window frames, and decorative elements. Overall, the choice of steel coil finish depends on the desired aesthetic outcome, as well as the specific requirements and intended application of the steel product.

- Q: What are the different methods of edge camber correction for steel coils?

- Edge camber correction in steel coils can be achieved through several methods, depending on specific requirements and available equipment. Some commonly used methods include the following: 1. Mechanical tools, such as shears or slitters, are utilized for trimming the edges of the coil. This removes excess material and corrects the camber. Mechanical edge trimming is suitable for smaller coils or minimal camber. 2. Tension leveling involves passing the coil through adjustable rollers while applying tension. This elongates the steel and reduces camber. It is effective for moderate camber and commonly used for larger coils. 3. Roller leveling, similar to tension leveling, employs fixed rollers to exert pressure on the steel and flatten it. This method is preferable for thicker and heavier coils. 4. Heat straightening utilizes controlled heat to soften the edges of the coil. Once the steel becomes malleable, external force is applied to straighten the edges. Heat straightening is suitable for severe edge camber but requires specialized equipment and expertise. 5. Combination methods may be employed by combining different techniques. For instance, mechanical edge trimming may be followed by tension leveling or roller leveling to further straighten the edges. It is important to note that the choice of method depends on factors such as camber severity, coil dimensions, material properties, and available equipment. Evaluating these factors and consulting with experts is essential to determine the most suitable method for edge camber correction in steel coils.

- Q: Specifically, for the main support beam found in a basement.

- Steel is better. You can use a smaller size compared to wood, it will handle more weight and will not deflect like a lam beam can and will. I've worked in a lot of older houses and the ones with steel beams always had far less differential settling than those with wood beams.

- Q: What is the role of steel coils in the manufacturing of storage racks?

- Steel coils play a critical role in the manufacturing of storage racks as they provide the raw material for creating the structural components of the racks. These coils are typically transformed through processes like cutting, bending, and welding to form the various parts of the racks, such as the upright frames, beams, and shelves. The strength and durability of steel make it an ideal material for storage racks, ensuring they can withstand heavy loads and provide long-lasting support for storing items efficiently.

Send your message to us

steel coil, prepainted steel coil,prepainted galvanized steel coil 9 J

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords