Hot Rolled Structure Steel Angle Bar Angle Steel JIS Standard GB Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specifications of Hot Rolled Angle Steel

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2. Invoicing on theoretical weight or actual weight as customer request3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR,S355JR;JISG3192,SS400;SS540.

4. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

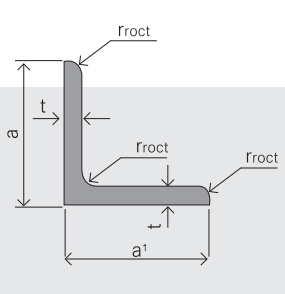

5.Sizes:

EQUAL ANGLES SIZES | |||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M/12M |

30 | 30 | 2.5---4.0 | 6M/12M |

38 | 38 | 2.5 | 6M/12M |

38 | 38 | 3.0---5.0 | 6M/12M |

40 | 40 | 3.0---6.0 | 6M/12M |

50 | 50 | 3 | 6M/12M |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

90 | 90 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

5. Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Packaging & Delivery of Equal Steel Angle

1.Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2.With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

- Q: Can steel angles be customized or fabricated to specific requirements?

- Yes, steel angles can be customized or fabricated to specific requirements.

- Q: Can steel angles be used for framing in residential construction?

- Yes, steel angles can be used for framing in residential construction. Steel angles are commonly used as structural elements in construction due to their strength and durability. They can be used to provide support and stability in various framing applications such as wall framing, roof trusses, and floor joists. Steel angles offer several advantages in residential construction, including their resistance to warping, shrinking, and rotting, making them a reliable choice for framing. Additionally, steel angles are fire-resistant, which adds an extra layer of safety in residential buildings. Overall, steel angles are a versatile and cost-effective option for framing in residential construction projects.

- Q: How do you design connections for steel angles?

- Designing connections for steel angles involves several key steps. Firstly, determine the loads that the connection will need to withstand, such as vertical and horizontal forces, moments, and shear forces. This will help determine the required strength and size of the connection. Next, select an appropriate connection type based on the specific application and load requirements. Common connection types for steel angles include bolted connections, welded connections, and a combination of both. In the case of bolted connections, design the connection by calculating the required number and size of bolts based on the applied loads. Consider factors such as bolt spacing and edge distances to ensure proper load transfer and prevent failure. For welded connections, ensure that the angles are properly prepared, aligned, and welded in accordance with the applicable codes and standards. Proper welding techniques and procedures should be followed to ensure the integrity and strength of the connection. During the design process, it is important to consider factors such as material properties, joint configurations, and the potential for corrosion or fatigue. Additionally, it is essential to consult relevant design codes and standards, such as the American Institute of Steel Construction (AISC) Manual, to ensure compliance and safety. Overall, designing connections for steel angles requires careful consideration of loads, connection types, and construction techniques to ensure a secure and reliable connection that meets the structural requirements.

- Q: Can steel angles be used as lintels?

- Certainly, steel angles have the ability to function as lintels. Due to their robustness and long-lasting nature, steel angles are frequently employed in construction as lintels. Lintels serve as essential components that bear the weight of walls above an aperture, like a door or window. The exceptional structural support and ability to withstand substantial loads make steel angles particularly suitable for this purpose. In masonry construction, they are frequently utilized to establish a sturdy and secure lintel. Moreover, steel angles can be effortlessly tailored to match precise measurements, rendering them a versatile option for lintel applications.

- Q: Are steel angles fire resistant?

- Steel angles are commonly regarded as fire resistant. This is because steel is a material that does not burn and can withstand high temperatures. Steel angles, which are L-shaped structural components, are widely used in construction and engineering due to their strength and durability. In the event of a fire, steel angles remain structurally intact and do not deform, which is crucial for the safety of a building or structure. However, it is important to consider that the fire resistance of steel angles may be influenced by various factors such as size, thickness, fire protection measures, and the duration and intensity of the fire. To enhance the fire resistance of steel angles and improve overall fire safety, measures like fire-resistant coatings, fire barriers, and fireproofing materials can be employed.

- Q: Are steel angles suitable for window frames?

- Yes, steel angles are suitable for window frames. Steel angles are often used in construction for their strength and durability, making them an ideal choice for supporting the weight of window frames. They provide excellent structural support, ensuring that the window frames remain stable and secure. Additionally, steel angles are resistant to corrosion, which is particularly advantageous for window frames that are exposed to external elements such as rain and humidity. Furthermore, steel angles can be easily fabricated and customized to meet specific design requirements, making them a versatile option for window frame construction. Overall, steel angles offer numerous benefits that make them a suitable choice for window frames in terms of strength, durability, corrosion resistance, and flexibility.

- Q: Can steel angles be used in the construction of bridges?

- Yes, steel angles can be commonly used in the construction of bridges. Steel angles are versatile structural components that can provide additional strength and support to bridge structures. They are often used in the construction of bridge decks, railings, and supports. Steel angles are known for their high strength-to-weight ratio, which makes them ideal for bridge construction. They can withstand heavy loads and provide stability to the bridge structure. Additionally, steel angles are durable and resistant to corrosion, which is essential for bridges that are exposed to various environmental conditions. In bridge construction, steel angles are often used in conjunction with other steel components, such as beams and columns, to create a strong and reliable structure. They are commonly used as bracing elements to reinforce the overall stability of the bridge. Steel angles can also be used as connection elements, allowing different parts of the bridge to be securely joined together. Overall, steel angles are a crucial component in bridge construction, providing strength, durability, and stability to the structure. Their versatility and reliability make them a preferred choice for engineers and designers when constructing bridges of various sizes and types.

- Q: What's the size of No. 5 angle iron?

- The size of No. 5 angle steel is: steel with length, width and height of 50*50*xmm, wherein X can be 3mm, 4mm, 5mm.

- Q: How do steel angles perform in corrosive gas or liquid environments?

- The strength and versatility of steel angles make them a popular choice for various structural applications. However, their performance in corrosive gas or liquid environments can be impacted by the grade of steel used and the concentration and nature of the corrosive substance. When exposed to corrosive gases or liquids, steel angles can undergo corrosion, leading to a gradual deterioration of their structural integrity. The extent of corrosion depends on factors such as exposure time, temperature, humidity, and the corrosiveness of the gas or liquid. To counteract the effects of corrosion, protective coatings can be applied to steel angles used in corrosive environments. Examples of common protective coatings include galvanization, which involves adding a layer of zinc to the steel surface, as well as epoxy or polyurethane coatings. These coatings create a barrier that prevents direct contact between the corrosive substance and the steel, thereby slowing down the corrosion process. However, it is important to acknowledge that even with protective coatings, steel angles may still experience some level of corrosion over time. The extent of corrosion will depend on the quality and durability of the coating, as well as the regular maintenance and inspection of the steel angles. In extremely aggressive or highly concentrated corrosive environments, steel angles may not be the most suitable choice. In such cases, alternative materials like stainless steel or corrosion-resistant alloys may be more appropriate. In conclusion, the performance of steel angles in corrosive gas or liquid environments is influenced by specific conditions and protective measures in place. Regular inspection, proper maintenance, and the use of suitable coatings are vital for ensuring the longevity and performance of steel angles in corrosive environments.

- Q: Can steel angles be painted or coated?

- Yes, steel angles can be painted or coated. Painting or coating steel angles can provide several benefits such as protection against corrosion, enhanced aesthetics, and improved durability. Prior to painting or coating, it is important to properly clean and prepare the surface of the steel angles to ensure good adhesion of the paint or coating. This typically involves removing any rust, grease, or dirt, and applying a suitable primer. Once the surface is properly prepared, a variety of paints or coatings can be applied, such as epoxy, polyurethane, or powder coatings. The choice of paint or coating will depend on the specific requirements of the application, such as the level of corrosion resistance or desired appearance. Overall, painting or coating steel angles is a common practice to enhance their performance and prolong their lifespan.

Send your message to us

Hot Rolled Structure Steel Angle Bar Angle Steel JIS Standard GB Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords