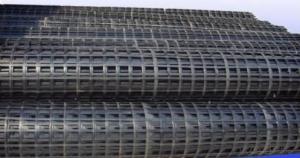

Standardpark Geocells Polypropylene Biaxial Geogrid with CE Certification

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction of PP Biaxial Geogrid

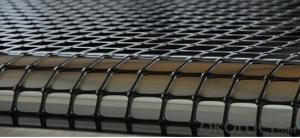

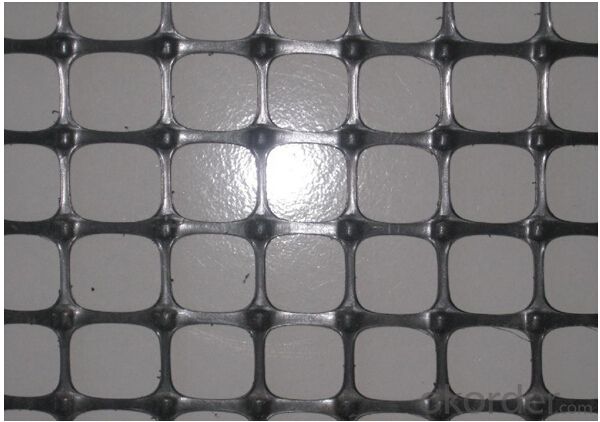

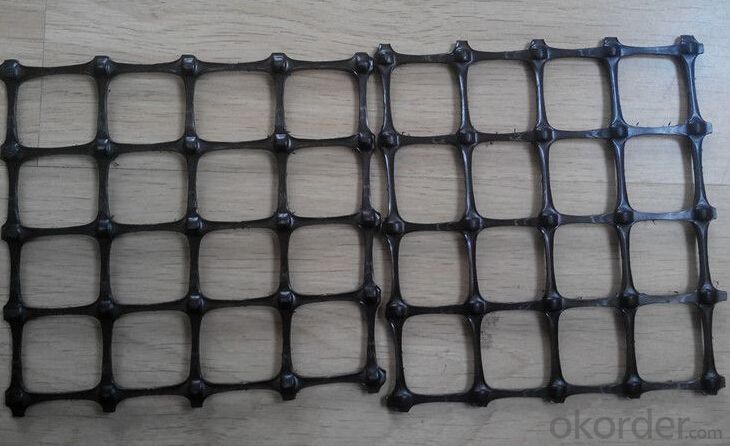

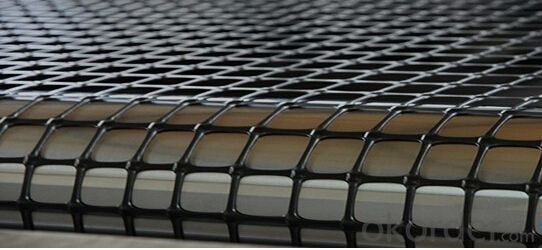

Biaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in longitudinal and transverse directions

2. Introduction of PP Biaxial Geogrid

1). With high tensile strength in longitudinal and transverse directions

2).This structure can provide an chain system of more effective force bearing and spreading for the soil.

3. Application of PP Biaxial Geogrid

1). With high tensile strength in longitudinal and transverse directions

2).This structure can provide an chain system of more effective force bearing and spreading for the soil

4. Technical Data and Specification of PP Biaxial Geogrid

Spec Item | TGSG15-15 | TGSG20-20 | TGSG30-30 | TGSG40-40 | TGSG45-45 |

Longitudinal Tensile Strength ≥(KN/m) | 15 | 20 | 30 | 40 | 45 |

Transverse Tensile Strength≥(KN/m) | 15 | 20 | 30 | 40 | 45 |

Longitudinal Elongation≤(%) | 15 | ||||

Transverse Elongation≤(%) | 13 | ||||

Longitudinal Strength at 2% Strain ≥(KN/m) | 5 | 7 | 10.5 | 14 | 16 |

Transverse Strength at 2% Strain ≥(KN/m) | 5 | 7 | 10.5 | 14 | 16 |

Longitudinal Strength at 5% Strain ≥(KN/m) | 7 | 14 | 21 | 28 | 32 |

Transverse Strength at 5% Strain ≥(KN/m) | 7 | 14 | 21 | 28 | 32 |

Remark | Roll Length:50m Roll width:1~4m | ||||

5. RFQ:

1) What's your payment terms?

T/T, L/C at sight, etc

2) What's your delivery time?

Within 15-20days against your deposit or original L/C received

3) Can you accept third party test?

Yes, we can accept it totally, SGS, BSJ, etc are no problem for us.

- Q: What are the advantages of using geogrids in mechanically stabilized aggregate bases?

- Some advantages of using geogrids in mechanically stabilized aggregate bases include increased load-bearing capacity, improved stability and performance, reduced construction and maintenance costs, and enhanced longevity of the pavement structure. Geogrids distribute and restrain the applied loads more evenly, reducing the stress on the underlying soil and aggregate layers. This results in higher load-bearing capacity and improved resistance against settlement, rutting, and pavement deformation. Additionally, geogrids help in maintaining the integrity of the aggregate base by preventing lateral spreading and enhancing interlocking between the aggregate particles. The use of geogrids also reduces the amount of aggregate material required for construction, leading to cost savings. Moreover, the improved stability provided by geogrids can extend the lifespan of the pavement structure, reducing the need for frequent maintenance and repairs.

- Q: What are the benefits of using geogrids in retaining walls?

- The benefits of using geogrids in retaining walls include increased stability, improved load-bearing capacity, reduced soil erosion, and longevity of the structure. Geogrids reinforce the soil, preventing it from sliding or collapsing under pressure, making the retaining wall more durable and resilient. Additionally, geogrids distribute the loads evenly, reducing the risk of settlement and enhancing the overall performance of the wall. They also enhance drainage and filtration, minimizing water buildup behind the wall and preventing soil erosion. Overall, geogrids help to ensure the longevity and effectiveness of retaining walls.

- Q: How do geogrids improve the bearing capacity of foundations?

- Geogrids improve the bearing capacity of foundations by providing reinforcement and stability to the soil. They act as a strong tensile element, distributing the load more evenly and reducing settlement. This helps to prevent soil movement and failure, ultimately increasing the overall strength and stability of the foundation.

- Q: What is the meaning of the geogrid reinforced asphalt in the project list

- You are not me, I was the construction of geogrid manufacturers, generally used in the mygeogrid on the road of geogrid is fiberglass geogrid, in your compacted Subgrade after injection will then laying a layer or several layers of fiberglass geogrid, after paving asphalt, the operation process is this, geogrid and asphalt is two kinds of different products

- Q: What are the specifications of the geogrid for road use?

- Warp knitted grating

- Q: Can geogrids be used in soil reinforcement for load-bearing platforms?

- Yes, geogrids can be effectively used in soil reinforcement for load-bearing platforms. Geogrids are engineered materials that provide soil stabilization and improve the load-bearing capacity of soils. They are typically made of high-strength polymers and have a grid-like structure that interlocks with the soil particles, creating a stable foundation. Geogrids distribute the applied loads more evenly, reducing the potential for soil settlement and enhancing the overall stability of load-bearing platforms.

- Q: How do geogrids enhance the stability of steep railway cuttings?

- Geogrids enhance the stability of steep railway cuttings by providing reinforcement and increasing the tensile strength of the soil. They are placed within the soil to distribute the stress and prevent sliding or collapse, effectively stabilizing the slope and minimizing erosion.

- Q: Are geogrids suitable for reinforcement of soft subgrades?

- Yes, geogrids are suitable for reinforcement of soft subgrades. Geogrids have been proven to effectively improve stability and strength in soft subgrade soils by distributing loads and reducing settlement. They provide additional tensile strength, preventing excessive deformation and enhancing the overall performance of the subgrade.

- Q: How much is the overlap length of Geogrid

- The horizontal distribution of shear walls should be staggered staggered 500mm, lap length 1.2LaE.

- Q: What are the installation guidelines for geogrids?

- The installation guidelines for geogrids typically include steps such as preparing the subgrade, ensuring proper compaction, rolling out the geogrid, anchoring it securely, and overlapping or connecting multiple rolls as necessary. It is important to follow the manufacturer's instructions and consult with an engineer or specialist to ensure correct installation and maximize the effectiveness of the geogrids.

Send your message to us

Standardpark Geocells Polypropylene Biaxial Geogrid with CE Certification

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords