Fireclay Brick - Standard Dimensions for Blast Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Refractory brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Main Feature:

The main chemical components: Al2O3 content is 30%-48%, SiO2 content is 50%-65%, and a small number of alkali metals, metal oxides, etc. Mineral composition is usually mullite, quartz and glass phase. Its refractoriness is 1580-1750 °C, refractoriness under load is 1250-1450 °C, with good thermal resistance and strong ability to resist acid slag.

Fire Clay Bricks is used for lower parts of regenerators, hot blast stove, furnaces of metallurgic, building material, glass, ferrous metal and so on.

Product Applications:

1. Furances of glass,coke oven,electric and so on

2.Furnaces of metallurgy industry, heat treatment furnace

3. Furnaces of chemical industry and construction industry.

4. Furnace of incineration of garbage, recirculating fluidized bed furnace

5. Standard sizing: 230 x 114 x 65 or 75 or 25 mm others up to the client

Specifications

1. Fire Caly brick Manufacturer

2. ISO 9001 certificate

3. Credible Quality

4. Reasonable price

5. Delivery in time

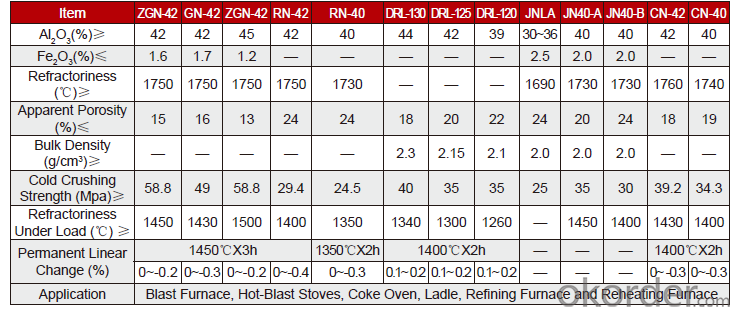

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: What material is sk-34 on the refractory brick

- Electric power; refractory bricks, castable refractory, building materials, chemical, glass, ferrous metals and other industries required refractory and insulation materials, all kinds of thermal insulation cotton products, thermal insulation brick, aluminous refractory cement, perlite and other unshaped refractory materials have been the best-selling products

- Q: What to do if refractory bricks saltpeter when they are used outdoor

- Efflorescence is usually dialysised from brickwork joints, dealing with the gap is ok These white substaince inside the pan tile: Cement efflorescence efflorescence is wow cake section from light leather intestinal common disease inumiya Hua building surface, according to their different causes and manifestations, there is pan cream, white, whitening, cream, on the walls and decorative surface erosion and other names, is the change of soluble saline alkali soil, adobe, brick, cement, mortar, concrete, masonry, ceramic tile, paint and other building materials with temperature, humidity and other external environment, in a water absorption, water transfer, water evaporation process with physical and chemical changes of the original building material damage disease phenomenon, erosion degree also has the very big difference there is a common, get damp, foaming, powder, drum, hollowing, cracking, spalling, mildew and crystallization phenomenon. Cement efflorescence may have some relationship with the quality of the cement, sand, water, air, temperature, humidity, it is a common fault in building. Use cement to do the pebble shape, it also prones to the above problems: A layer of white stuff on the surface. Terms of settlement: Scrape the dust in brickwork joint, pointing again. Use special pointing agents, more resistant to corrosion, not easy to efflorescence.

- Q: Can refractory be used to sharpen knife?

- Many factories build a smelting furnace by using this kind of bricks. A special knife grinder can be used to sharpen knife, can on 1. They are sizing and non-sizing refractory bricks respectively. Refractory brick is now a lot of fields and industry will introduce one of the raw materials. Products are divided into two different types, refractory brick as a high temperature resistance of the raw materials. In simple terms, working temperature is 770 DEG C, 580 C and 1, of course, refractory bricks also can be used to sharpen knife, use smooth brick to sharpen, need to choose high hardness

- Q: Can common cement mortar be used to build the lining of chimney refractory brick?

- No. You have used fire bricks, which shows there is a certain temperature inside, you'd better use refractory cement

- Q: What are the simple ways to distinguish between excessive clay bricks and less fired clay bricks?

- When the production of sintered clay brick, brick baking in an oxidizing environment and a kiln, produce red brick; if the first brick in an oxidizing roasting, and then watering stuffy kiln, the kiln to form reducing atmosphere, makes the three brick red iron oxide is reduced to a high oxygen low iron and preparation so blue. The durability of brick brick than good.

- Q: How aluminium oxide becomes a entity from the the form of powder (such as a ball, a stone, or a refractory brick)?

- Just like the process of making steamed bun from flour. Ball milling ---in the auxiliary material to make the slurry --- suppress the body --- high temperature calcination

- Q: How many degrees of refractory brick if its surface turns red, how to test the temperature of refractory brick after it is burnt to red.

- Dark red? Bright red? Orange red? 400,1100 or 1500 probably

- Q: What are the type, location and the physical and chemical effects of the refractory brick used in the cement rotary kiln?

- And T209

- Q: What materials mix mortar to build walls (with bricks)? The more burned the harder

- Refractory cement, refractory mortar, refractory mud

- Q: does all the refractory refer to refractory bricks when making steel?

- Not only are refractory bricks, and shapeless refractory material; blowing agents, drainage sand, and oxygen are all metallurgical auxiliary materials.

Send your message to us

Fireclay Brick - Standard Dimensions for Blast Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords