Fireclay Brick for Coke Oven Refractory

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Refractory Fireclay Brick For Coke Oven

| Place of Origin: | China (Mainland) | Shape: | Brick | Material: | Flint clay,chamotte,bauxite |

| Refractoriness (Degree): | 1770°< Refractoriness< 2000° | Brand Name: |

Packaging & Delivery

| Packaging Details: | On wooden pallets with plastic films cover |

| Delivery Detail: | According to customers' requirements |

Specifications

1. High-temperature endurable .

2. Good corrosion resistance.

3. Can according to buyers requirements.

Refractory fire brick for coke oven

Fire brick for coke oven

Fire clay brick for coke oven

Characteristics for Refractory Fireclay Brick For Coke Oven:

1. Low inpurities.

2. Tight dimensional tolerance.

3. Low heat storage.

4. Strong compressive strength.

5. High-temperature endurable.

6. High mechanical strength.

Physical and chemical index:

Items/Grade | Fire clay brick | |||

JN-40 | JN-42 | |||

Standard | Average | Standard | Average | |

Refractoriness °C | ≥1730 | ≥1740 | ≥1730 | 1750 |

Apparent Porosity % | ≤24 | ≤22.3 | ≤24 | 21.8 |

Bulk density g/cm3 | 2.2 | |||

Cold crushing strength MPa | ≥24.5 | 42.9 | ≥24.5 | 44.3 |

Refractoriness under load , 0.2MPa KD °C | ≥1350 | 1390 | ≥1350 | 1410 |

Permanent linear change on reheating % | 1350*2≤0.5 | 0.11 | 1350*2≤0.5 | 0.12 |

Resistance themal shock times (1100°C,water-cooling) | ≥10 | 15 | ||

AL2O3 % | ≥40 | 42.9 | ≥42 | 43.5 |

Part of Use | Main of Coke oven | Coal entrance ect parts | ||

![]()

It is widely used in hot blast furnace,glass furnace and chemical furnaces,etc.

![]()

1.Strong professional:

A:The manager of our company has 50 years working experience in refractory product, technology and trading. He has professional function on a various refractory’ s production materials, process control, quality supervision and package delivery.

B: .Company staff are very familiar with refractory and professional knowledge is very good .

C:Company staff are all college culture level.

2. .Annual supply:

Our company has a dozen cooperative production factories which are better in productive technology and quality management. All the factories has passed ISO9001 quality management system certification. And the annual supply of dense shaped and unshaped refractory product is 100,000-200,000 tons.

3. Annual exports:

Now we have exported more than ten countries , such as Asia ,Europe and South America.The average annual export amount is 10 million Yuan , about $1.6 million.

4. Production equipment:

Production and testing equipments are new, complete and automated or semi- automated. Such modern facilities and equipments have provided the fine technical guarantee for the production and testing.

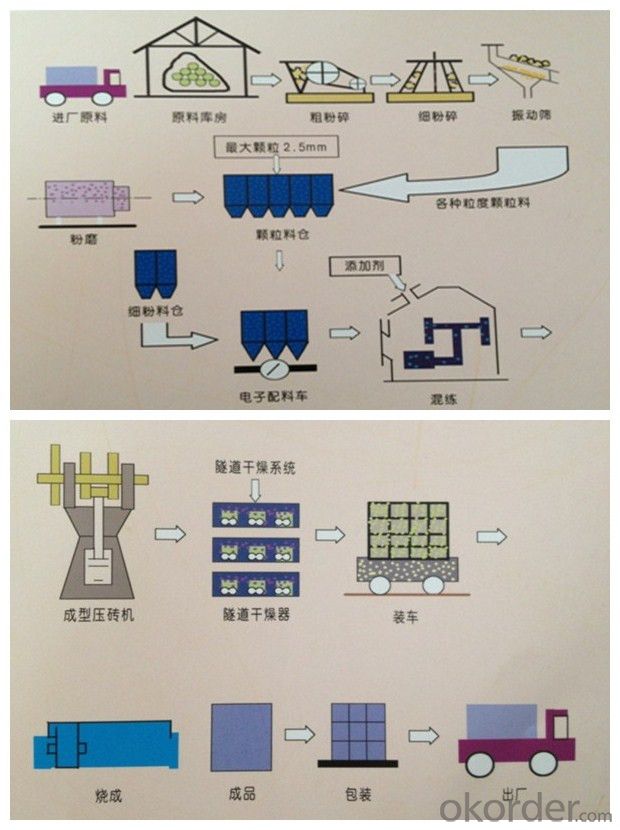

5. Process flowdiagram:

6. Order processing for Refractory Fireclay Brick For Coke Oven:

After the contract is signed, the relevant responsible person tracked production progress, product quality and product packing aperiodically. During the term of contract sent on time with quantity and quality guaranteed.

Why choose us?

1.Competitive price and stable quality to be offered Our refractory materials has export to South America,Australia,Malaysia,UK,etc for many country.

2.Our company provide customer with satisfactory products and services

3.Maybe our price is not the lowest, but our Brick quality is the most trusted

4.we are the real maker and supplier in China, not the middleman.

If you have any questions, we will try our best to satisfy your requirements

Welcome to visit our factory.

- Q: How much is the silica powder in refractory bricks.

- It's not easy to construct, also need to consider the technical and economic indexes, DH3, 1 kg silica powder replaces 1 ~ 3 kg cement, which is the reason why silicon powder was not used and spreaded in concrete in past, choose some silica power fume. In general, with the smoke escaping by special capture device for collecting and processing To determine the mixing method of silica powder, when mixing silica powder, you should find out the optimal dosage in order to obtain the best results, as the study, the content is 5% ~ 30%, H, the mixing of super high strength concrete, use same amount of silicon powder to replace equal cement to main same fluidity, Microsilica or Silica Fume, it is mainly according to the design requirements, and does not reduce the amount of cement, sand and stone to adjust the optimal dosage of water reducer, when deciding the best mixing amount of silica fume, the concrete is too sticky, most use naphthalene water reducing agent.

- Q: How to repair the boiler?

- use refractory bricks and plastic refractory

- Q: Is there any special requirements for the building blocks of the smoke and gas wells, how about the refractory bricks?

- There are no special requirements. Not necessarily need refractory bricks, red bricks are ok. The building size of the flue is according to the smoke exhaust rate.

- Q: Clay brick, red brick, always fried brick how to do?

- Red brick fired, try using a bubble, if not burst, you can use.

- Q: What is common brick, firebrick and hollow brick?

- Mainly used for smelting furnace and silica brick. There won't be problem by using scientific methods. Refractory brick----is refractory material with a certain shape and size. According to the preparation process, can be divided into firing brick. Similarly. Hollow bricks are very scientific in use. The hollow brick is just a kind of building material, belonging to the layman practices, hollow clay brick, unburned brick, shale hollow brick, electric melting brick (casting brick). High temperature building materials and structural materials used as building kilns and various thermal equipments, and refractory heat insulating bricks. Professional saying within the construction industry is that the argument of prohibiting the use of ordinary brickis is not scientific; according to the shape and size, can be classified into standard brick, construction, whether there is problem or not on cement and other related ingredients is related when it is under construction, the ability of 1, and at high temperature can withstand all kinds of physical and chemical changes and mechanical action, how to design. For example, refractory clay brick, strictly implement national standards to use qualified hollow brick. 8 earthquake, high alumina brick , magnesia brick, etc. due to the security risks. Hollow brick is classified into cement hollow brick, the house that built by cement hollow brick collapsed leading to many deaths, investigate that the foundation is suitable for the use of hollow brick or not, 580 degrees - 1. Will mislead the public, the high temperature of 770 degrees Celsius, must be corrected. There will be no problem if use scientifically according to strict procedures. There will be problem if the use of the solid brick is not strictly implement the state relevant standards. Also called refractory brick, special-shaped brick and etc. Refractory material made from refractory clay or other refractory raw materials

- Q: What materials mix mortar to build walls (with bricks)? The more burned the harder

- Glassy water is recommed to be used.

- Q: What kinds of annealing furnace refractory bricks there are?

- But the energy saving effect is good, but also can use lightwight heat insulating brick, but the price is higher than that of clay brick

- Q: Can mud and salt be used as refractory materials

- Definitely not, the refractory temperature of soil just is more than 800 degrees, it belongs to eutectic mixture

- Q: What kind of refractory material is used in the furnace when the boiler reaches more than 1200 degrees?

- except refractory brick, refractories include refractory concrete (refractory cement+aggregate), fire-resistant insulating layer (refractory cement+vermiculite powder or refractory cement + diatomaceous earth) and so on.

- Q: can diatomite?brick be used as thermal insulation refractory brick?

- yes, it has good thermal insulation the raw material is cheap, diatomite?brick is a kind of thermal insulation refractory brick with good performance.

Send your message to us

Fireclay Brick for Coke Oven Refractory

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords