Fireclay Brick for Hot Blast Furnace 1250-1450 ℃

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

What is the feature of Fireclay Brick?

l Fireclay Bricks or fire bricks are the most widely used refractory bricks because of its great features: low thermal conductivity, good thermal insulation performance; High resistance to Thermal shock, abrasion, chemical attack to provide long service life; easy operation and installation; broad usage or applications and low price etc.

l High density with low porosity fire clay bricks is our featured product in this category. Due to its low apparent porosity rate, high density with low porosity bricks have great features of strong resistance to erosion, high refractoriness under load, great Cold Crushing strength and high mechanical strength etc.

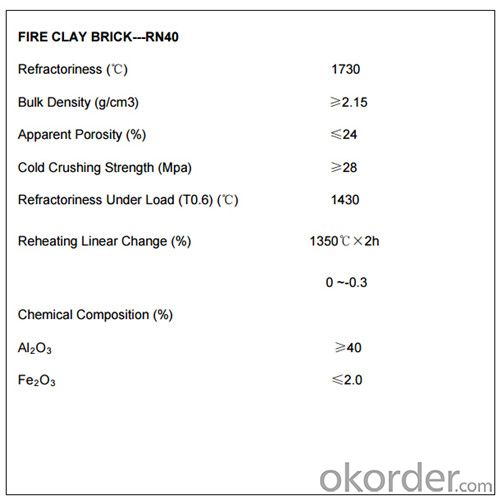

Technical Data of Fireclay Brick

Image of Fireclay Brick

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisor.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days

for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: what is consequence of high load and soft low of high alumina refractory brick ?

- softening, if not up to the design requirements, may cause vicious incident like the collapse of the stove in use. the full name is softening temperature under a fixed load, as the name suggests, it is the softening temperature after adding the load.

- Q: What are required for high temperature refractory bricks?

- good thermal shock resistance:

- Q: What are 85 bricks, 95 bricks and standard bricks? What are the specifications?

- Clay to clay (including shale, coal gangue powder) as the main raw material, through mud processing, molding, drying and roasting and.

- Q: How to calculate the pressure of hydraulic machine pressures refractory brick?

- If it is a plunger type cylinder, the pressure of a cylinder is the cross-sectional area of the piston multiplied by the pressure of the hydraulic system; if it is piston cylinder, that is the inner diameter of the hydraulic cylinder multiplied by the pressure of the hydraulic system. Adopt cm as diameter's unit, a unit of pressure is kilogram force per square centimeter, the calculated result is kilogram which divided by one thousand is ton.

- Q: What are the specifications of clay brick and cement brick construction?

- Chinese in the spring and Autumn period has created a square and brick, Qin and Han Dynasties brick technology and production scale, quality and variety have significant development, known as "Qin Zhuanhan tile".

- Q: Do cement kiln refractory bricks have quality guarantee period? can them still be used for a long time's pile?

- They of course can be used. The plant will produce some bricks for standby application in advance, so they put for a period of time is completely no problem

- Q: What are the sizes and sizes of clay bricks?

- According to the compressive strength (Newton / square millimeter, N/mm2) the size is divided into MU30, MU25, MU20, MU15, MU10, MU7.5, these 6 intensity levels.The bigger the size, the stronger the compressive strength.

- Q: T38 size of high alumina refractory brick

- high alumina brick, according to the aluminum content, is divided into four grades, the aluminum content of the first grade is no less than 75%, also called the special high alumina brick; the aluminum content of the second grade is no less than 65%, the third grade is no less than 55%; the aluminum content of super high aluminium brick is more than 85%; If the shape is very irregular, it is usually called the super special high alumina brick. in short, there is a universal type of high alumina brick except for standard high alumina brick, customised according to the specific appliction of the kiln.

- Q: What are the physical and chemical properties of refractory bricks

- The thermal shock stability, linear?change?on?reheating, softening temperature under a fixed load, compressive strength under normal strength refractoriness

- Q: Can porous clay bricks be made of 12 walls to bear weight?

- A porous clay brick, made of 12 walls, does not bear weight. The wall is too thin. The load-bearing wall needs 24 walls at least.

Send your message to us

Fireclay Brick for Hot Blast Furnace 1250-1450 ℃

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords