Fireclay Bricks - High Density for Blast Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

High density Fireclay bricks for Blast Furnace is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High density Fireclay bricks for Blast Furnace are made of selected high alumina bauxite, kaolin clay, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature

Product Applications:

1. Furances of glass,coke oven,electric and so on

2.Furnaces of metallurgy industry, heat treatment furnace

3. Furnaces of chemical industry and construction industry.

Main Product Features:

1. Low porosity,High bulk density.

2. High Cold Crushing strength.

3. High refractoriness under load.

Product Specifications:

1.With 55% Al2O3 min;

2. Refractoriness: 1750C min;

3.For steelmaking furnaces;

4.ISO 9001 Certificate;

5.Custom shape;

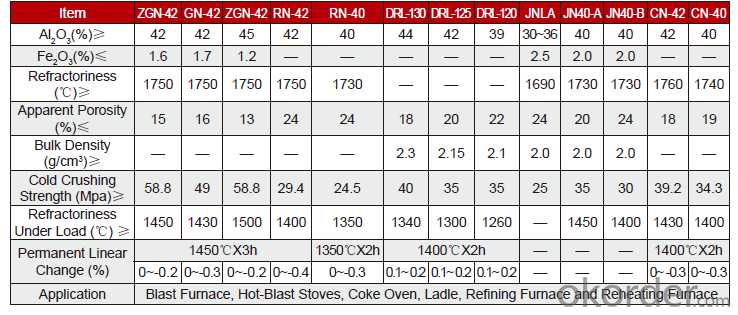

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: The furnace refractory bricks are burnt into ash, what material can resist higher temperature than the refractory brick

- steel plate is ok

- Q: Is the quality of refractory brick influenced if it is soaked by water

- No refractory brick is not afraid of water

- Q: Do refractory bricks need to be sent to the lab to test after arriving the site?

- Generally speaking, as long as the use of temperature is not higher than 1500 degrees, it is not required to do the test, even if the ordinary refractory brick temperature is about 1500. If the temperature is high, then you do test to determine what kind of texture of refractory brick you need

- Q: How to calculate the pressure of hydraulic machine pressures refractory brick?

- If it is a plunger type cylinder, the pressure of a cylinder is the cross-sectional area of the piston multiplied by the pressure of the hydraulic system; if it is piston cylinder, that is the inner diameter of the hydraulic cylinder multiplied by the pressure of the hydraulic system. Adopt cm as diameter's unit, a unit of pressure is kilogram force per square centimeter, the calculated result is kilogram which divided by one thousand is ton.

- Q: Whether the fire bricks are needed to be poured before construction?

- Of course, the purpose of watering is to reduce the bricks to absorb water in mortar

- Q: What is the density of the high alumina refractory brick?

- it depends on the aluminum content, the higher it contains, the larger the density is. the hjghest is 3, the lowest is 2.

- Q: T38 size of high alumina refractory brick

- 230*114*65/55

- Q: is there any requirement for radioactive materials in refractory materials.

- they all do not cause radiological hazards to the environment, so no requirements! analyze rom the element , magnesia. Do not know if it is useful, but material used by refractory materials, firstly any chemical elements are radioactive, human beings can not close, then, such as silicon dioxide: If it is radioactive. analyze from use, such as bauxite, does not have the use value

- Q: Do refractory bricks resist corrosion and sulfur?

- There are anticorrosion and acid proof refractory bricks

- Q: What is the main use of refractory brick?

- Refractory bricks are mostly used as furnace lining amd air heating furnace in high temperature industry Such as the iron and steel industry blast furnace, colored reverberatory furnace, converter

Send your message to us

Fireclay Bricks - High Density for Blast Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords