stainless steel slab stocks

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

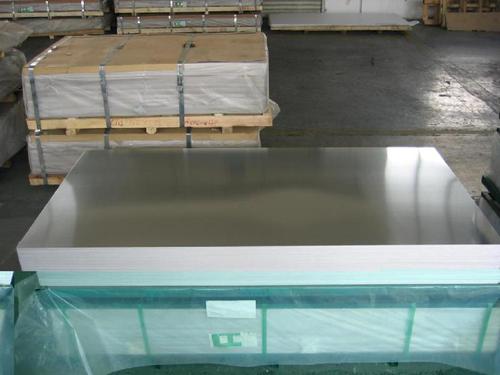

1、Structure of 304/2B STAINLESS STEEL SHEET.

STAINLESS STEEL SHEET IS ONE POPULAR PRODUCTS IN CHINA MARKET, IT HAVE SEVERAL DIFFERENT APPLICATIONS, SUCH AS, CONSTRUCTION, BUILDING, DECORATION, ETC.

THE GRADE ALSO INCLUDE: 200 SERIES, 300 SERIES, 400 SERIES, ETC.

Mainly applied in the industry of furniture, sports equipment, compressed containers, shipbuilding, railway and the automotive.

2、Main Features of the 304 STAINLES STEEL SHEET.

High intensity

Low welding costs.

Outstanding color compatibility after anodizing

Easy to operate. All-position welding.

Excellent corrosion resistance

Wide applicability.

Length per spool only for reference

WIDTH*LENGTH: 1219MM*2438MM, 1500MM*3000MM, 1500MM*6000MM,ETC.

THE THICKNESS IS NORMALLY FROM 0.1MM TO 3MM, THEY ARE THE COLD ROLLED SHEET.

5、FAQ of 304/2B STAINLESS STEEL SHEET.

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

----Now we export to South East Asia,Africa, North America,South America ect.

- Q: How do you calculate the cost of a stainless steel sheet?

- Calculating the cost of a stainless steel sheet involves taking into account several factors. To begin, it is necessary to determine the dimensions of the sheet, including its length, width, and thickness. These measurements will dictate the amount of material required, which is a crucial aspect in determining the cost. Another factor to consider is the grade of the stainless steel sheet. Different grades, such as 304, 316, or 430, possess distinct properties and are associated with varying costs. The specific grade necessary for a particular application will influence the sheet's price. The finish of the stainless steel sheet is also important to consider. Options like brushed, polished, or patterned finishes all entail different processes and materials, which in turn impacts the cost. Additionally, the quantity of stainless steel sheets needed can affect the overall cost. Bulk orders are often eligible for discounted prices, while smaller quantities may incur higher expenses. Conducting thorough research on different suppliers is crucial. Prices can fluctuate depending on factors such as the supplier's location, reputation, and prevailing market conditions. Comparing prices among various suppliers is essential to obtain the most favorable cost. It is worth noting that there may be additional costs involved, such as transportation fees, handling charges, or cutting fees. It is advisable to inquire about these potential expenses when requesting quotes from suppliers. By taking these factors into consideration and conducting comprehensive research, it is possible to accurately calculate the cost of a stainless steel sheet.

- Q: Can stainless steel sheets be used for automotive applications?

- Yes, stainless steel sheets can be and are commonly used for various automotive applications. This is due to their excellent corrosion resistance, durability, and aesthetic appeal, making them suitable for components such as exhaust systems, body panels, trim, and interior parts in automobiles.

- Q: Are stainless steel sheets suitable for pharmaceutical cleanrooms?

- Yes, stainless steel sheets are highly suitable for pharmaceutical cleanrooms. Stainless steel is a preferred material in cleanroom environments due to its inherent qualities such as corrosion resistance, durability, and ease of cleaning. It is non-porous, making it resistant to bacteria, mold, and other contaminants. Additionally, stainless steel is able to withstand frequent sanitization procedures without deteriorating, making it a reliable choice for maintaining a clean and sterile environment in pharmaceutical cleanrooms.

- Q: Are stainless steel sheets suitable for outdoor sculptures or decorative pieces?

- Outdoor sculptures or decorative pieces can be made using stainless steel sheets. Stainless steel is a material that is both durable and resistant to corrosion, making it perfect for enduring harsh outdoor conditions. It does not rust, corrode, or stain, meaning it will maintain its attractive appearance over time. Moreover, stainless steel sheets can be easily shaped and welded into different forms, allowing artists to create intricate and detailed sculptures or decorative pieces. Additionally, stainless steel has a sleek and modern look that can enhance the overall beauty of outdoor spaces. In conclusion, stainless steel sheets are an excellent option for outdoor sculptures or decorative pieces because of their durability, resistance to corrosion, and aesthetic appeal.

- Q: How do you remove adhesive residue from stainless steel sheets?

- To remove adhesive residue from stainless steel sheets, you can follow these steps: 1. Start by gently scraping off as much of the residue as possible using a plastic scraper or your fingernail. Be careful not to scratch the stainless steel surface. 2. Next, dampen a soft cloth with warm water and mild detergent or dish soap. Gently scrub the adhesive residue using circular motions. Avoid using abrasive cleaners or scrub brushes as they can damage the stainless steel finish. 3. If the adhesive residue persists, you can try using a non-abrasive cleaner specifically designed for stainless steel. Apply a small amount of the cleaner to a soft cloth and gently rub the residue until it lifts off. 4. For stubborn adhesive residue, you can make a paste using baking soda and water. Apply the paste to the affected area and let it sit for a few minutes. Then, use a soft cloth to gently scrub off the residue in circular motions. 5. Rinse the stainless steel sheet thoroughly with warm water to remove any remaining residue or cleaner. 6. Finally, dry the surface with a clean, soft cloth to prevent water spots and streaks. Remember to always test any cleaning method or product on a small, inconspicuous area of the stainless steel sheet before applying it to the entire surface. This will ensure that it doesn't cause any damage or discoloration.

- Q: Can stainless steel sheets be used in manufacturing processes?

- Yes, stainless steel sheets can be used in manufacturing processes. Stainless steel is a highly versatile and durable material that is commonly used in various industrial applications. Due to its corrosion resistance, strength, and heat resistance properties, stainless steel sheets are ideal for manufacturing processes that require a material to withstand harsh conditions, such as chemical processing, food and beverage production, pharmaceutical manufacturing, and automotive manufacturing. Stainless steel sheets can be formed, cut, welded, and machined to suit specific manufacturing requirements, making them a popular choice in the industry.

- Q: Can stainless steel sheets be used for food packaging equipment?

- Food packaging equipment can utilize stainless steel sheets, as they possess several desirable qualities. Due to their durability, corrosion resistance, and hygienic properties, stainless steel is a popular choice for food processing and packaging equipment. Notably, it is non-reactive, ensuring that the food's quality and taste remain unaffected. Moreover, stainless steel sheets are easily cleaned and sanitized, making them appropriate for use in food packaging equipment where cleanliness and hygiene are vital. Additionally, the smooth surface of stainless steel prevents food particles from adhering to the equipment, further enhancing its usability. In summary, stainless steel sheets offer a dependable and secure solution for food packaging equipment.

- Q: What are the different types of corrosion that stainless steel sheets can resist?

- Compared to other metals, stainless steel sheets possess remarkable corrosion resistance. They can withstand several forms of corrosion, including: 1. Uniform corrosion: This occurs when the entire surface of the stainless steel sheet is exposed to a corrosive environment. However, stainless steel contains a minimum of 10.5% chromium, which creates a protective oxide layer on the surface, halting further corrosion. 2. Pitting corrosion: Pitting corrosion causes small pits or holes on the stainless steel sheet's surface. Thanks to its high chromium content, stainless steel forms a passive film that prevents pitting corrosion from advancing. 3. Crevice corrosion: This type of corrosion happens in cramped spaces or gaps where stagnant corrosive substances can accumulate. Stainless steel sheets resist crevice corrosion by maintaining their passivity and preventing the buildup of corrosive agents. 4. Stress corrosion cracking (SCC): SCC arises from the combined effects of a corrosive environment and tensile stress. Stainless steel sheets are built to withstand SCC due to their high alloy content and the formation of a protective passive film. 5. Intergranular corrosion: Intergranular corrosion affects the grain boundaries of stainless steel, making it prone to cracking and weakening. However, stainless steel sheets are typically crafted with low carbon content to prevent intergranular corrosion and ensure their durability. In general, stainless steel sheets are highly resistant to various forms of corrosion, making them the preferred choice for multiple applications in industries such as construction, food processing, and marine engineering.

- Q: How are stainless steel sheets used in the construction industry?

- Due to their remarkable properties and versatility, stainless steel sheets find extensive use in the construction industry. These sheets are highly valued for their durability, resistance to corrosion, and aesthetic appeal. Roofing and cladding are among the primary applications of stainless steel sheets in construction. They are commonly employed for roof panels, wall panels, and façade systems. Stainless steel sheets provide exceptional protection against weather elements, including rain, snow, and UV rays. Moreover, they offer corrosion resistance, ensuring the long-lasting nature of the building's exterior. Furthermore, stainless steel sheets are frequently utilized in the construction of architectural structures such as bridges and tunnels. Their high strength-to-weight ratio makes them well-suited for such purposes. Stainless steel sheets can withstand heavy loads and provide reliable support, thus guaranteeing the structural integrity of these infrastructures. Additionally, stainless steel sheets are employed in the construction of interior components like elevator doors, escalators, and handrails. Their sleek and modern appearance adds an elegant touch to the overall design. Moreover, these sheets are hygienic and easy to clean, making them perfect for applications in hospitals, laboratories, and food processing facilities. In conclusion, stainless steel sheets are indispensable in the construction industry. They are utilized for roofing, cladding, architectural structures, and interior components. With their exceptional durability, corrosion resistance, and aesthetic appeal, stainless steel sheets contribute significantly to the longevity and aesthetic value of various construction projects.

- Q: Are stainless steel sheets good for industrial exhaust systems?

- Yes, stainless steel sheets are an excellent choice for industrial exhaust systems. They offer high resistance to corrosion, extreme temperatures, and chemicals typically found in exhaust gases. Additionally, stainless steel sheets have excellent durability and strength, making them suitable for heavy-duty industrial applications.

Send your message to us

stainless steel slab stocks

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords