Stainless Steel NO.1 Finish Grade 304 Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

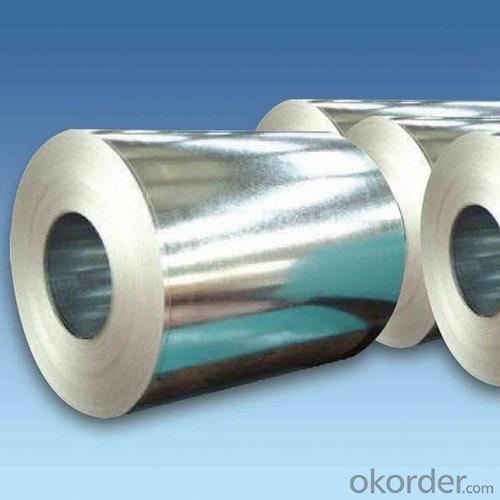

Products Description for Stainless Steel Coils/Sheets:

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: Thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Detail picture for Stainless Steel Coils/Sheet

Payment&Delivery for Stainless Steel Coils/Sheets:

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

Export Markets for Stainless Steel Coils/Sheets:

Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

FAQ for Stainless Steel Coils/Sheets:

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: Can stainless steel sheets be used outdoors?

- Indeed, outdoors can accommodate the use of stainless steel sheets. Its exceptional resistance to corrosion renders it an impeccable option for outdoor purposes. The material can endure exposure to moisture, humidity, and even the harshest weather conditions without succumbing to rust or deterioration. Consequently, stainless steel sheets become fitting for an array of outdoor applications, including building facades, roofing, fencing, outdoor furniture, and decorative elements. Furthermore, stainless steel boasts durability, effortless maintenance, and an elegant aesthetic, solidifying its status as a widely favored choice for outdoor utilization in residential, commercial, and industrial environments.

- Q: Can stainless steel sheets be used for railway infrastructure?

- Yes, stainless steel sheets can be used for railway infrastructure. Stainless steel is a versatile and durable material that offers various advantages for railway applications. Its corrosion resistance properties make it suitable for outdoor and high humidity environments, which are common in railway infrastructure. Stainless steel sheets can withstand harsh weather conditions, including extreme temperatures, rain, and UV radiation, without corroding or deteriorating. This makes them ideal for railway tracks, bridges, tunnels, and other structures that are exposed to the elements. Additionally, stainless steel sheets have excellent strength-to-weight ratio, allowing for the construction of lightweight yet sturdy railway infrastructure. This reduces the load on the overall structure and facilitates easier transportation and installation. Stainless steel is also resistant to fire and can withstand high impact, making it a reliable choice for railway applications where safety is a priority. Furthermore, stainless steel sheets are easy to clean and maintain, which is beneficial for railway infrastructure that requires regular upkeep. They can be easily polished to restore their aesthetic appeal and maintain a clean appearance. Stainless steel is also recyclable, making it an environmentally friendly choice for sustainable railway construction. In summary, stainless steel sheets can indeed be used for railway infrastructure due to their corrosion resistance, strength, durability, fire resistance, ease of maintenance, and sustainability.

- Q: 304 stainless steel plate price ups and downs affected by what factors?

- Some monopolies or monopolies combine to control prices. The indirect regulation of some large enterprises also has a partial effect on the price of stainless steel.

- Q: Can stainless steel sheets be used in architectural applications?

- Yes, stainless steel sheets can be used in architectural applications. Stainless steel is a versatile material that offers excellent strength, durability, and corrosion resistance, making it suitable for a wide range of architectural projects. It is commonly used for cladding, roofing, and facade applications, as well as for structural elements such as columns and beams. Stainless steel sheets can be fabricated into various shapes and sizes, allowing architects to achieve unique designs and create visually appealing buildings. Additionally, stainless steel's aesthetic appeal, with its sleek and modern look, is often sought after in contemporary architecture. Overall, stainless steel sheets are a popular choice in architectural applications due to their functionality, durability, and aesthetic qualities.

- Q: What are the weight calculations for stainless steel sheets?

- The weight calculations for stainless steel sheets can be determined using the following formula: Weight (in pounds) = Thickness (in inches) x Width (in inches) x Length (in inches) x Density (in pounds per cubic inch) The density of stainless steel typically ranges from 0.283 to 0.305 pounds per cubic inch, depending on the specific alloy used. Therefore, it is important to determine the specific density value for the particular grade of stainless steel being used. For example, let's say we have a stainless steel sheet with a thickness of 0.125 inches, a width of 36 inches, and a length of 72 inches. If the density of the stainless steel is 0.283 pounds per cubic inch, the weight calculation would be: Weight = 0.125 inches x 36 inches x 72 inches x 0.283 pounds per cubic inch = 91.368 pounds So, the weight of this stainless steel sheet would be approximately 91.368 pounds.

- Q: Are stainless steel sheets resistant to scaling?

- Yes, stainless steel sheets are highly resistant to scaling. Due to their chromium content, they form a protective layer that prevents oxidation and scaling even at high temperatures.

- Q: Are stainless steel sheets heat-resistant?

- Yes, stainless steel sheets are heat-resistant. Stainless steel is known for its ability to withstand high temperatures without warping or deforming, making it an excellent choice for applications that involve heat exposure. The chromium content in stainless steel forms a protective layer on the surface, which helps to prevent oxidation and corrosion even at elevated temperatures. This heat resistance property makes stainless steel sheets suitable for a wide range of applications, including industrial equipment, kitchen appliances, automotive parts, and construction materials.

- Q: How do you polish stainless steel sheets?

- To polish stainless steel sheets, you can start by cleaning the surface thoroughly to remove any dirt or grime. Then, use a stainless steel cleaner or a mixture of mild detergent and warm water to wipe the sheets in the direction of the grain. Next, rinse the sheets with clean water and dry them with a soft cloth. Finally, apply a stainless steel polish or a mixture of vinegar and olive oil to a clean cloth, and gently buff the sheets in circular motions to restore their shine and remove any remaining stains or smudges.

- Q: How do you cut intricate designs in stainless steel sheets?

- One effective way to cut intricate designs in stainless steel sheets is by using a laser cutting machine. Laser cutting technology allows for precise and intricate cuts, making it ideal for complex designs. The laser beam melts, burns, or vaporizes the material, resulting in a clean and accurate cut without the need for additional finishing. This method ensures high-quality and precise cuts in stainless steel sheets.

- Q: Can stainless steel sheets be used for food processing equipment?

- Yes, stainless steel sheets can be used for food processing equipment. Stainless steel is a popular choice for such applications due to its corrosion resistance, easy cleaning properties, and hygienic characteristics. It is able to withstand high temperatures, is non-reactive with food, and does not impart any taste or odor.

Send your message to us

Stainless Steel NO.1 Finish Grade 304 Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords