Stainless steel plate/sheet 304,201,202,316L,316Ti,304L,410,420,430,444

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless steel plate/sheet

304,201,202,310S,309S,316L,316Ti,321,304L,410,420,430,444,443,409L,904L

| Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

| Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

| Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

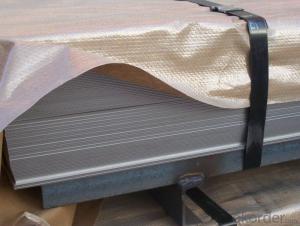

| Packaging | Standard export sea-worthy packing |

| Delivery time | 10-30 days |

| Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

| Quality | No.1 |

| Productivity | 1200ton/day |

| Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

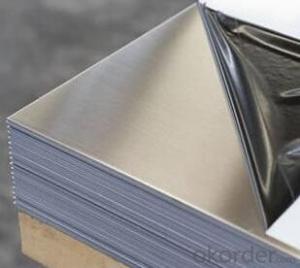

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K |

Product Shows :

Application :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Packaging and Loading

- Q: What are the different types of stainless steel sheet surface coatings available?

- There are several types of stainless steel sheet surface coatings available, including brushed or satin finishes, mirror finishes, bead blasted finishes, and embossed or textured finishes.

- Q: Are stainless steel sheets resistant to chemicals and acids?

- Stainless steel sheets possess resistance against chemicals and acids, thanks to the high percentage of chromium they contain. This results in the formation of a protective layer on the metal's surface, granting it exceptional resistance to corrosion and damage caused by chemicals and acids. Moreover, the inclusion of elements like nickel and molybdenum further enhances this corrosion-resistant quality. Industries like chemical processing, pharmaceuticals, food and beverage, and automotive widely employ stainless steel sheets due to their exposure to aggressive chemicals and acids. The reliability and durability of stainless steel in withstanding corrosion and chemical attack render it an ideal material for applications requiring such resistance.

- Q: Why do drill holes burn on stainless steel plates? What's the best way to drill them?

- The cutting fluid is made of concentrated emulsions. Commonly used stainless steel drills are: high cobalt bit (M35 bit, M42 bit), in which the M42 bit is the most cost-effective, and carbide drills are also available.

- Q: Can stainless steel sheets be used for medical implants or devices?

- Stainless steel sheets have the potential to serve as medical implants or devices. Thanks to its exceptional corrosion resistance, strength, and biocompatibility, stainless steel is a frequently utilized material in medical implants and devices. Its applications encompass orthopedic implants (such as hip replacements and bone plates), surgical instruments, dental implants, and cardiovascular devices. By precisely fabricating stainless steel sheets into the required shape and size, durability and long-term functionality in diverse medical applications can be ensured. Moreover, the ease with which stainless steel can be sterilized renders it suitable for employment in medical settings.

- Q: Are stainless steel sheets resistant to intergranular corrosion?

- Yes, stainless steel sheets are generally resistant to intergranular corrosion due to the presence of chromium in their alloy composition. Chromium forms a protective oxide layer on the surface of stainless steel, preventing corrosive substances from penetrating the material and causing intergranular corrosion.

- Q: Are stainless steel sheets suitable for outdoor furniture?

- Yes, stainless steel sheets are highly suitable for outdoor furniture. Stainless steel is known for its exceptional durability, resistance to corrosion, and ability to withstand various weather conditions. It also offers a sleek and modern appearance, making it a popular choice for outdoor furniture that can withstand the elements and maintain its aesthetic appeal.

- Q: How do I clean and maintain stainless steel sheets?

- To clean and maintain stainless steel sheets, follow these simple steps: 1. Start by removing any loose dirt or debris from the surface using a soft cloth or sponge dampened with warm water. 2. For tougher stains or fingerprints, mix a mild detergent with warm water and apply it to the sheet using a non-abrasive sponge or cloth. Gently scrub the affected area in the direction of the grain. 3. Rinse the sheet thoroughly with clean water to remove any residue from the detergent. 4. Dry the stainless steel sheet with a soft cloth to prevent water spots or streaks from forming. 5. To maintain the shine and protect against future stains, apply a small amount of stainless steel cleaner or polish to a clean, soft cloth. Rub the surface in the direction of the grain, avoiding circular motions. 6. Wipe off any excess cleaner or polish with a separate clean cloth to ensure an even finish. 7. For stubborn stains or scratches, you can use a stainless steel cleaner that contains mild abrasives. However, be cautious as these products may scratch the surface if used improperly. 8. Avoid using abrasive sponges, steel wool, or harsh chemicals as they can damage the stainless steel surface. 9. Regularly dust the stainless steel sheets with a soft cloth to prevent the accumulation of dirt or dust particles. 10. Lastly, remember to always refer to the manufacturer's instructions for specific cleaning and maintenance recommendations for your particular stainless steel sheet product.

- Q: What are the advantages of using stainless steel sheets in the medical industry?

- There are several advantages of using stainless steel sheets in the medical industry: 1. Hygiene and Cleanliness: Stainless steel is a non-porous material, which makes it easy to clean and disinfect. It is resistant to bacteria, mold, and other pathogens, making it an ideal choice for medical equipment, surgical instruments, and even hospital furniture. 2. Durability and Longevity: Stainless steel is highly durable and can withstand harsh conditions, including high temperatures, humidity, and corrosive substances. This ensures that medical equipment and instruments made from stainless steel sheets have a longer lifespan, reducing the need for frequent replacements. 3. Strength and Safety: Stainless steel sheets offer excellent strength and structural integrity, making them suitable for applications that require resistance to impact and pressure. This is crucial in the medical industry, where instruments and equipment undergo constant use and handling. 4. Resistance to Stains and Corrosion: Stainless steel is highly resistant to stains and corrosion, even in aggressive environments. This property is essential in medical facilities where exposure to various chemicals and liquids is common. The resistance to corrosion ensures that stainless steel sheets remain intact and do not release harmful substances into the environment. 5. Aesthetic Appeal: Stainless steel sheets have a sleek and modern appearance that adds to the overall aesthetic appeal of medical equipment and instruments. This can create a positive impression on patients, instilling confidence in the quality and cleanliness of the medical facility. 6. Recyclability: Stainless steel is a sustainable material as it can be recycled without any loss in quality. This reduces the environmental impact of the medical industry by minimizing waste and conserving resources. In conclusion, the advantages of using stainless steel sheets in the medical industry include hygiene, durability, strength, resistance to stains and corrosion, aesthetic appeal, and recyclability. These qualities make stainless steel a reliable and cost-effective choice for medical equipment, instruments, and other applications in healthcare settings.

- Q: Can stainless steel sheets be used for elevator doors?

- Yes, stainless steel sheets can be used for elevator doors.

- Q: What's the difference between stainless steel hot rolling and cold rolling?

- 1. cold-rolled steel plate due to a certain degree of hardening, low toughness, the price is more expensive;2. surface anaerobic cold rolling scale, good quality;3. cold deformation products, high dimensional accuracy, good surface quality;4. cold rolling because of its production process in all walks of life in a wide range of applications, such as various types of cold stamping parts, cold rolled cold extrusion profiles, cold coil spring, cold drawn wire, cold heading bolts.Hot rolling (hot rolling): relative to cold rolling, cold rolling is performed under recrystallization temperature, while hot rolling is rolling above recrystallization temperature.

Send your message to us

Stainless steel plate/sheet 304,201,202,316L,316Ti,304L,410,420,430,444

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords