Stainless Steel Sheet/Plate 409 for Auto Vent Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 8500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Sheet/Plate 409 for Auto Vent Pipe

Description of Stainless Steel Sheet/Plate 409 for Auto Vent Pipe:

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widelyused in light industry,heavy industry,daily necessities and the decoration industry.my company long-termsupply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube.

Main Features of Stainless Steel Sheet/Plate 409 for Auto Vent Pipe:

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Application of Stainless Steel Sheet/Plate 409 for Auto Vent Pipe:

Stainless steel’s resistance to corrosion and staining, low maintenance and familiar lustre make it an ideal material for many application

s.There are over 150 grades of stainless steel, of which fifteen are most commonly used. The alloy is milled into coils, sheets, plates,

bars, wire, and tubing to be used in cookware, cutlery, household hardware, surgical instruments, major appliances, industrial equipme

nt Storage tanks and tankers used to transport orange juice and other food are often made of stainless steel, because of its corrosion re

sistance and antibacterial properties. This also influences its use in commercial kitchens and food processing plants, as it can be steam

cleaned and sterilized and does not need paint or other surface finishes..

Specifications of Stainless Steel Sheet/Plate 409 for Auto Vent Pipe:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Surface Finish Characteristics Stainless Steel Sheet/Plate 409 for Auto Vent Pipe:

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

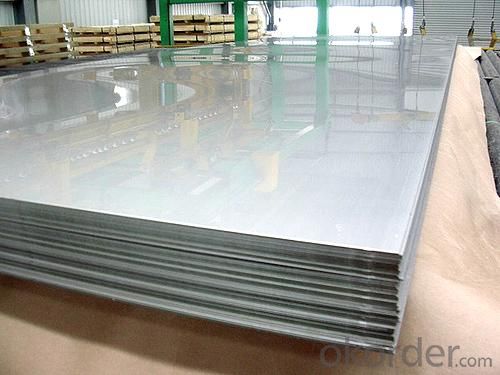

Images of Stainless Steel Sheet/Plate 409 for Auto Vent Pipe:

Sandard Seaworth Packing(wooden packing with water proof paper):

FAQ of Stainless Steel Sheet/Plate 409 for Auto Vent Pipe:

1. What are we supplying?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently supplying grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321, 410/420/430/443/444/409L, and 904L.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: What is the standard size of a stainless steel sheet?

- The standard size of a stainless steel sheet can vary depending on the manufacturer and the specific application. However, in general, stainless steel sheets are commonly available in standard sizes of 4 feet by 8 feet (1220mm by 2440mm) or 4 feet by 10 feet (1220mm by 3050mm). These dimensions are widely used in various industries such as construction, manufacturing, and fabrication. Additionally, stainless steel sheets may also come in different thicknesses, ranging from 0.4mm to 6mm or more, depending on the intended use and requirements. It is important to note that custom sizes and dimensions can also be obtained from manufacturers for specific projects or applications that require non-standard sizes.

- Q: What are the common types of corrosion that affect stainless steel sheets?

- There are several common types of corrosion that can affect stainless steel sheets. One of the most common types is known as pitting corrosion. Pitting corrosion occurs when localized areas of the stainless steel surface become damaged, resulting in small pits or holes. This type of corrosion is typically caused by exposure to chlorides, such as saltwater or certain chemicals. Another common type of corrosion is known as crevice corrosion. Crevice corrosion occurs in tight spaces or crevices where oxygen and other corrosive agents may become trapped. This can happen in areas where stainless steel sheets are joined or in areas where dirt, debris, or moisture can accumulate, creating an environment conducive to corrosion. Galvanic corrosion is another type that can affect stainless steel sheets. This occurs when stainless steel comes into contact with a dissimilar metal in the presence of an electrolyte, such as moisture. The difference in electrical potential between the two metals can result in a flow of electrical current, leading to corrosion of the stainless steel. Stress corrosion cracking is a type of corrosion that occurs under tensile stress, combined with exposure to a corrosive environment. This type of corrosion can cause cracking or fracturing of stainless steel sheets, compromising their structural integrity. Lastly, intergranular corrosion is a type of corrosion that occurs along the grain boundaries of stainless steel. This can result from improper welding practices, exposure to high temperatures, or chemical exposure. Intergranular corrosion can weaken the stainless steel sheets and make them more susceptible to other forms of corrosion. It is important to consider these common types of corrosion when working with stainless steel sheets, as they can impact the performance and durability of the material. Proper maintenance, regular inspections, and appropriate corrosion prevention measures can help mitigate the risk of corrosion and prolong the lifespan of stainless steel sheets.

- Q: Can stainless steel sheets be used for outdoor railings?

- Yes, stainless steel sheets can be used for outdoor railings. Stainless steel is a popular choice for outdoor applications due to its durability and resistance to corrosion. It is able to withstand exposure to various weather conditions, such as rain, snow, and sunlight, without deteriorating or rusting. Stainless steel railings provide a sleek and modern look to outdoor spaces, while also offering strength and stability. Additionally, stainless steel is low maintenance and easy to clean, making it an ideal material for outdoor railings that may be subjected to dirt, dust, or other debris. Overall, stainless steel sheets are an excellent choice for outdoor railings, offering both aesthetic appeal and long-lasting performance.

- Q: What are the benefits of using embossed stainless steel sheets in elevator doors?

- Using embossed stainless steel sheets in elevator doors offers several advantages. Firstly, the embossed pattern enhances the aesthetic appeal of the elevator interior, creating a luxurious and sophisticated atmosphere for passengers. Secondly, these sheets are highly durable and resistant to scratches, dents, and corrosion. Elevator doors are prone to damage due to frequent use, but the use of embossed stainless steel sheets ensures that the doors remain in pristine condition for a longer time. This durability reduces maintenance and replacement costs over the elevator's lifespan. Additionally, embossed stainless steel sheets provide a high level of hygiene. The inherent resistance of stainless steel to bacteria and germs makes it an ideal material for elevator doors. The embossed pattern also helps hide fingerprints and smudges, ensuring that the doors stay clean and sanitary with minimal maintenance. Moreover, embossed stainless steel sheets offer excellent fire resistance properties. In case of a fire, these sheets help contain the flames and prevent the spread of fire, providing an added level of safety for passengers in the enclosed space of the elevator. Lastly, embossed stainless steel sheets are easy to clean and maintain. With their smooth surface and resistance to stains and dirt, these sheets can be easily wiped down with a mild cleaner, saving time and effort in the cleaning process. In conclusion, the benefits of using embossed stainless steel sheets in elevator doors include improved aesthetics, durability, hygiene, fire resistance, and ease of maintenance. These advantages make embossed stainless steel sheets a popular choice for elevator manufacturers and building owners alike.

- Q: Can stainless steel sheets be used for water purification systems?

- Yes, stainless steel sheets can be used for water purification systems. Stainless steel is a popular material choice for water purification systems due to its corrosion resistance, durability, and hygienic properties. It is highly resistant to rust and can withstand harsh environmental conditions, making it suitable for long-term use in water treatment applications. Additionally, stainless steel is non-reactive and does not leach harmful substances into the water, ensuring the purity and safety of the treated water. The smooth and non-porous surface of stainless steel also makes it easy to clean and maintain, minimizing the risk of bacterial growth and contamination. Overall, stainless steel sheets are an excellent choice for constructing various components of water purification systems, including tanks, filters, and pipes.

- Q: Are stainless steel sheets resistant to lactic acid?

- Stainless steel sheets are commonly resistant to lactic acid. The corrosion resistance of stainless steel is well-known, and lactic acid is generally not potent enough to cause substantial harm to surfaces made of stainless steel. Nevertheless, the level of resistance may differ based on the specific grade and quality of stainless steel employed. To ensure the suitability of stainless steel sheets for applications involving lactic acid, it is advisable to seek guidance from a material expert or conduct appropriate testing.

- Q: Is there any magnetism in 304 stainless steel?

- Stainless steel friends are many, there are some differences in color, but not very good to distinguish. Can be judged according to the magnetic (magnet test): magnetic was 202 (ferritic stainless steel) magnetic or nonmagnetic small is 304 (stainless steel), are generally magnetic, but strength difference.

- Q: Can stainless steel sheets be used for kitchen appliances?

- Yes, stainless steel sheets can be used for kitchen appliances. Stainless steel is a popular material choice for kitchen appliances due to its durability, resistance to corrosion, and easy maintenance. It is commonly used for making ovens, refrigerators, dishwashers, and other kitchen appliances. Stainless steel sheets are versatile and can be easily formed into various shapes and sizes to fit different appliance designs. Additionally, stainless steel has a sleek and modern appearance, making it a preferred choice for many homeowners and chefs.

- Q: Are stainless steel sheets resistant to alkaline solutions?

- Generally, stainless steel sheets are resistant to alkaline solutions. They have a reputation for being corrosion-resistant and can tolerate exposure to various chemicals, including alkalis. The protective oxide layer on the surface, formed by the high chromium content in stainless steel, aids in preventing corrosion and deterioration. However, it's worth noting that the resistance of stainless steel to alkaline solutions may differ depending on the specific grade and composition. In certain instances, prolonged exposure to highly concentrated alkaline solutions or aggressive alkaline substances could potentially harm the stainless steel surface. Therefore, it is advisable to consult the manufacturer or supplier to ensure the appropriate grade of stainless steel is chosen for specific alkaline applications.

- Q: Are stainless steel sheets good for industrial exhaust systems?

- Yes, stainless steel sheets are an excellent choice for industrial exhaust systems. They offer high resistance to corrosion, extreme temperatures, and chemicals typically found in exhaust gases. Additionally, stainless steel sheets have excellent durability and strength, making them suitable for heavy-duty industrial applications.

Send your message to us

Stainless Steel Sheet/Plate 409 for Auto Vent Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 8500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords