Stainless Steel Sheet 0.8mm thickness with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/310S/309S/316L/316Ti/316/321/410/420/430/444/443/409L,and 904L.

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

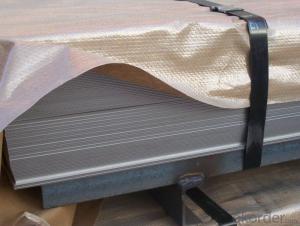

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Cold Rolled and Hot Rolled:

Packing and Loading:

FAQ:

1. What's the quality?

Very fine, we have been exported to more than 30 countries.

2. How long get reply?

Usually within 24 hours

If you have any question about stainless steel sheets, do not forget to send the email to us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Stainless steel without fingerprint processing how to get?

- Anti fingerprint (also known as non fingerprint) stainless steel plate is a protective layer treatment process is extremely thin and solid formed on the surface of stainless steel by nano coating technology, the stainless steel surface can not only achieve the anti fingerprint effect, also can improve the anti corrosion resistance;

- Q: What are the different types of stainless steel sheet surface coatings for outdoor applications?

- Outdoor applications commonly use various types of stainless steel sheet surface coatings. These coatings aim to enhance the stainless steel's durability and corrosion resistance, making it suitable for harsh outdoor environments. One commonly used coating for outdoor applications is powder coating. This involves applying a dry powder to the stainless steel surface and then curing it under heat to create a protective layer. Powder coating offers excellent resistance against corrosion, UV rays, and chemicals, making it perfect for outdoor use. Furthermore, it provides a wide range of color options, allowing for customization and aesthetic appeal. Another type of coating frequently employed for outdoor applications is PVD (Physical Vapor Deposition) coating. This process entails depositing a thin film of material onto the stainless steel surface using a vacuum chamber. PVD coatings offer outstanding adhesion, wear resistance, and corrosion resistance, making them suitable for outdoor use. They also provide various decorative finishes like gold, bronze, or black, which can enhance the stainless steel's appearance. In addition, stainless steel can be coated with ceramic for outdoor applications. Ceramic coatings are typically applied using a high-temperature spray process, resulting in a hard, protective layer on the stainless steel surface. These coatings offer superior resistance against abrasion, chemicals, and UV rays, making them ideal for highly durable outdoor applications. To summarize, stainless steel sheet surface coatings for outdoor applications include powder coating, PVD coatings, and ceramic coatings. Each of these coatings offers distinct benefits in terms of corrosion resistance, durability, and aesthetic appeal, enabling the use of stainless steel in a wide range of outdoor environments.

- Q: Are stainless steel sheets suitable for outdoor signage?

- Yes, stainless steel sheets are highly suitable for outdoor signage. They are durable, weather-resistant, and able to withstand harsh outdoor conditions such as rain, sun exposure, and extreme temperatures. Stainless steel sheets also offer a sleek and modern aesthetic, making them an ideal choice for outdoor signage that needs to be both functional and visually appealing.

- Q: Can stainless steel sheets be used for elevator door frames?

- Yes, stainless steel sheets can be used for elevator door frames. Stainless steel is a durable and corrosion-resistant material, making it suitable for such applications where strength and aesthetics are important.

- Q: Are stainless steel sheets suitable for heat transfer equipment?

- Stainless steel sheets are indeed a suitable option for heat transfer equipment. The reason lies in the remarkable thermal conductivity properties of stainless steel, enabling it to effectively transfer heat between different mediums. Its ability to endure high temperatures without warping or deforming makes it particularly well-suited for heat transfer applications. Moreover, stainless steel's resistance to corrosion guarantees the equipment's durability and longevity. Additionally, its hygienic qualities make it a fitting choice for industries such as food and pharmaceuticals, where cleanliness is of utmost importance. In conclusion, stainless steel sheets are a dependable and efficient selection for heat transfer equipment.

- Q: Can stainless steel sheets be etched or engraved?

- Yes, stainless steel sheets can be etched or engraved. Etching and engraving are common methods used to create designs, patterns, and text on stainless steel surfaces. These techniques involve removing a thin layer of the metal to create the desired design. Etching can be done using chemicals or by using a laser, while engraving is typically done using a mechanical tool or laser. The etching or engraving process can create intricate and detailed designs on the stainless steel sheets, making them suitable for a wide range of applications such as signage, decorative panels, nameplates, and more.

- Q: Can stainless steel sheets be used for marine propellers?

- Yes, stainless steel sheets can be used for marine propellers. Stainless steel is a popular choice for marine propellers due to its excellent corrosion resistance properties. The high levels of chromium in stainless steel make it resistant to rust and other forms of corrosion, even in saltwater environments. Additionally, stainless steel offers good strength and durability, making it suitable for withstanding the harsh conditions of marine environments. Stainless steel propellers are often preferred for boats and ships as they require less maintenance and have a longer lifespan compared to other materials. However, it is important to choose the appropriate grade of stainless steel for marine propellers to ensure optimal performance and longevity.

- Q: How do you calculate the weight of a stainless steel sheet?

- To calculate the weight of a stainless steel sheet, you need to know its dimensions (length, width, and thickness) and the specific gravity of stainless steel. First, determine the volume of the stainless steel sheet by multiplying the length, width, and thickness together. This will give you the volume in cubic units. Next, multiply the volume by the specific gravity of stainless steel, which is typically around 7.93 g/cm³ (grams per cubic centimeter). This will give you the weight of the stainless steel sheet in grams. To convert the weight to a different unit, such as kilograms or pounds, divide the weight in grams by the appropriate conversion factor. For example, to convert grams to kilograms, divide by 1000. To convert grams to pounds, divide by 453.59237. It is important to note that this calculation provides an estimate of the weight, as there may be slight variations in the specific gravity of stainless steel depending on the exact alloy and composition of the sheet.

- Q: What are the costs of stainless steel sheets compared to other materials?

- The costs of stainless steel sheets tend to be higher compared to other materials such as aluminum or carbon steel. This is primarily due to the higher production and fabrication costs associated with stainless steel, as well as its superior corrosion resistance and durability, which make it a popular choice for various applications. However, it's important to consider the long-term benefits and value that stainless steel offers, making it a worthwhile investment in many cases.

- Q: Can stainless steel sheets be used for medical implant devices?

- Medical implant devices can utilize stainless steel sheets, as they possess excellent mechanical properties, corrosion resistance, and biocompatibility. Stainless steel is widely employed in the medical field due to its strength, durability, and ability to endure sterilization processes. Various medical implant devices, including plates, screws, and pins used in orthopedic surgeries, dental implants, cardiovascular devices, and other procedures, can be fabricated from stainless steel sheets. The high strength-to-weight ratio of stainless steel makes it suitable for applications requiring load-bearing capabilities, while its resistance to corrosion ensures longevity within the body. Moreover, stainless steel is a biocompatible material, meaning it is well-tolerated by the human body and does not cause adverse reactions or allergies. Techniques like passivation or coating can enhance the biocompatibility of stainless steel surfaces. It is vital to emphasize that selecting the appropriate stainless steel grade and surface finish is essential for medical implant devices to ensure compatibility with specific body tissues and environments. Thorough testing and regulatory approval are also necessary to guarantee the safety and effectiveness of stainless steel medical implant devices. To summarize, stainless steel sheets can indeed be utilized for medical implant devices due to their mechanical properties, corrosion resistance, and biocompatibility. Ensuring the suitability and safety of stainless steel implants in medical applications necessitates proper selection, testing, and regulatory approval.

Send your message to us

Stainless Steel Sheet 0.8mm thickness with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords