stainless steel round bar

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless Steel round Bar

Specifications

stainless steel round bar1.Specification:12-300mm

2.Material:304 316

3.Length:standard 6m

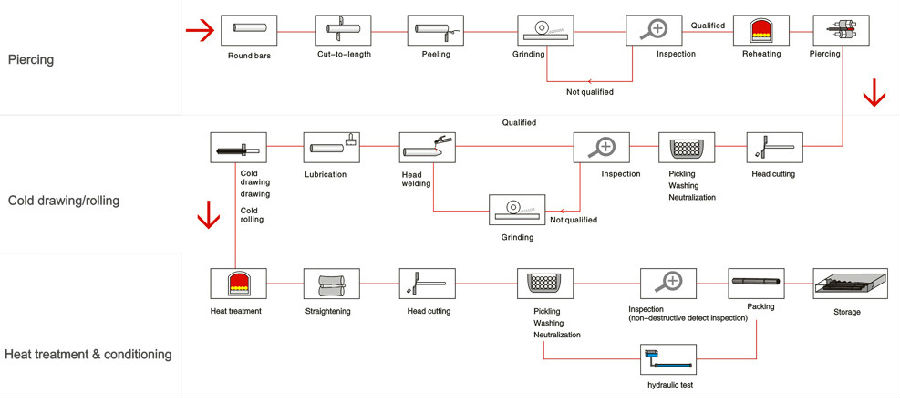

A series of pictures

- Q: Round stainless steel bar is formed after how to deal with customers?

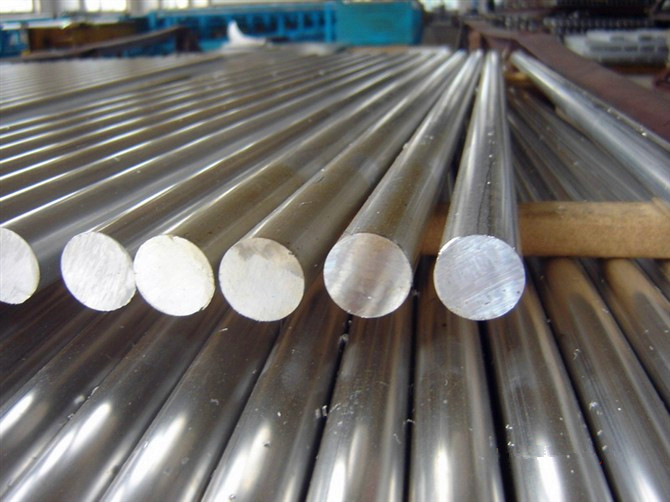

- Hello, stainless steel round surface is bright, is the hot rolled stainless steel rod after cold drawing of cold rolling mill, the surface layer of the black color to remove.

- Q: How do stainless steel bars compare to carbon steel bars?

- The composition, properties, and applications of stainless steel bars and carbon steel bars are distinctly different. Let's start with their composition. Stainless steel bars are primarily made of iron, with the addition of elements like chromium, nickel, and others. These added elements give stainless steel its unique corrosion-resistant properties, making it highly resistant to rust and stains. Conversely, carbon steel bars are mainly composed of iron and carbon, with small amounts of other elements. The absence of chromium and nickel in carbon steel makes it more susceptible to corrosion and rust compared to stainless steel. Moving on to properties, stainless steel bars offer superior strength and durability compared to carbon steel bars. They have a high tensile strength, enabling them to withstand heavy loads and resist deformation. Moreover, stainless steel bars have excellent heat and temperature resistance, making them ideal for high-temperature applications. On the other hand, carbon steel bars, while strong, generally have lower tensile strength and are more prone to deformation when subjected to heavy loads. Lastly, their applications differ significantly. Stainless steel bars are widely used in industries that require corrosion resistance, such as the production of kitchen utensils, medical equipment, and chemical processing plants. They are also commonly utilized in construction, automotive, and aerospace industries due to their strength and durability. In contrast, carbon steel bars find frequent use in applications that prioritize strength and cost-effectiveness over corrosion resistance. Examples include construction, manufacturing machinery, and infrastructure projects. To summarize, stainless steel bars and carbon steel bars exhibit differences in composition, properties, and applications. Stainless steel bars are renowned for their corrosion resistance, strength, and durability, making them suitable for various industries and applications. On the other hand, carbon steel bars, although less resistant to corrosion, offer strength and cost-effectiveness, making them ideal for applications that prioritize strength over corrosion resistance.

- Q: What is the hardness of 416 stainless steel bars after heat treatment?

- Martensitic stainless steel refers to the stainless steel that can be adjusted to its mechanical properties by overheating. It is, in general, a hardened stainless steel, typically of type Cr13. After quenching the hardness is higher, different tempering temperature has different strength and toughness combination, mainly used in steam turbine blades, tableware, surgical instruments.

- Q: What are the standard tolerances for stainless steel bars?

- The standard tolerances for stainless steel bars vary depending on the specific dimensions and requirements. However, common industry tolerances for stainless steel bars typically range within +/- 0.005 to 0.010 inches for diameter or thickness, and +/- 0.030 to 0.060 inches for length. It is important to note that these tolerances may vary depending on the specific grade and application of the stainless steel bars.

- Q: What are the different types of stainless steel bars used in musical instruments?

- There are several different types of stainless steel bars that are commonly used in musical instruments. One of the most commonly used types is 304 stainless steel, which is known for its excellent corrosion resistance and high strength. This type of stainless steel bar is often used in instruments such as drums, cymbals, and other percussion instruments. Another type of stainless steel bar commonly found in musical instruments is 316 stainless steel. This particular grade of stainless steel is highly resistant to corrosion and is often used in instruments that are exposed to moisture, such as brass instruments like trumpets and trombones. In addition to these two popular grades, there are also other types of stainless steel bars used in musical instruments. For instance, 430 stainless steel is often used in the construction of saxophones due to its high heat resistance and excellent durability. Furthermore, 17-4 PH stainless steel is another type that is commonly used in the construction of guitar strings due to its high tensile strength and resistance to wear. Overall, the choice of stainless steel bar used in musical instruments depends on the specific requirements of the instrument and the desired characteristics, such as corrosion resistance, strength, and durability. Each type of stainless steel offers its own unique set of qualities, ensuring that the instrument meets the necessary standards and delivers the desired sound quality.

- Q: Do stainless steel bars have good resistance to sulfuric acid?

- Yes, stainless steel bars have good resistance to sulfuric acid. Stainless steel is known for its corrosion-resistant properties and it is widely used in various industries due to its excellent resistance to many corrosive environments, including sulfuric acid. The high levels of chromium and nickel present in stainless steel help in forming a passive layer on the surface, which protects the material from the corrosive effects of sulfuric acid. Additionally, stainless steel has good mechanical strength and can withstand the high temperatures associated with sulfuric acid applications. However, it is important to note that the resistance of stainless steel to sulfuric acid depends on factors such as the concentration and temperature of the acid, so it is advisable to consult with experts or refer to the specific grade of stainless steel being used to determine its suitability for a particular sulfuric acid application.

- Q: Do stainless steel bars have good resistance to oxidation?

- Yes, stainless steel bars have excellent resistance to oxidation. This is mainly due to the presence of chromium in their composition, which forms a protective layer of chromium oxide on the surface of the bars. This oxide layer acts as a barrier, preventing oxygen from reaching the underlying metal and thus inhibiting the oxidation process. Additionally, stainless steel bars also contain other alloying elements like nickel and molybdenum which further enhance their resistance to oxidation in various environments, including high temperatures and corrosive conditions. Therefore, stainless steel bars are widely used in applications where resistance to oxidation is crucial, such as in the manufacturing of industrial equipment, automotive parts, and construction materials.

- Q: Are stainless steel bars suitable for the production of cutting tools?

- Yes, stainless steel bars are suitable for the production of cutting tools. Stainless steel is known for its high strength, durability, and resistance to corrosion, making it an excellent choice for cutting tools that require sharpness and longevity. Additionally, stainless steel can be hardened and tempered to enhance its cutting performance, making it a preferred material in the manufacturing of various cutting tools such as knives, scissors, and blades.

- Q: Can stainless steel bars be bent or formed?

- Yes, stainless steel bars can be bent or formed, although the process may be more challenging compared to other materials. Stainless steel has a higher strength and hardness compared to other metals, which makes it more resistant to deformation. However, with the use of specialized machinery and techniques such as cold bending or hydraulic bending, stainless steel bars can be bent or formed into various shapes and angles. It is important to note that the specific type and grade of stainless steel, as well as its thickness, will influence the ease and limitations of the bending process. Additionally, excessive bending or forming may cause the stainless steel to lose some of its corrosion resistance properties, so it is crucial to follow proper procedures and consult with experts when working with stainless steel bars.

- Q: Do stainless steel bars have good wear resistance?

- Yes, stainless steel bars have excellent wear resistance due to their unique composition and properties. The addition of chromium in stainless steel enhances its corrosion resistance and provides a protective layer, which also contributes to its wear resistance.

Send your message to us

stainless steel round bar

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords