Stainless steel round bar, angle bar, flat bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

1. Material: AISI 201, 202, 304, 304L, 316, 316L, 321, 310S, 410, 416, 420, 430, 431, 904L etc.

2. MOQ: 500 Kg

3. Mill test

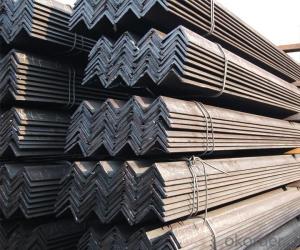

Stainless steel round bar, angle bar, flat bar, square bar, hexagon bar, triangle bar:

Products' basic information:

1. standard: ASTM 276

2. length: standard 5.8 meters-6 meters each piece of the bar or according to buyers' request

3. material: AISI 201, 202, 304, 304L, 316, 316L,316ti, 321, 310S, 410, 416, 420, 430, 431, 904L, UNS S32304, UNS S31803, UNS S32205, UNS S32750, UNS S32760, UNS S32550, etc

No.1: stainless steel round bar (two series:black surface& bright surface)

round bar (black surface):

No.2: stainless steel angle bar

No.3: stainless steel flat bar (two series:pickled white surface& polished bright surface)

-flat bar (pickled white surface):

No.4: stainless steel square bar

No.5: stainless steel hexagon bar

Know more about trade...

Payment term: 1. 30% T/T in advance, and the balance against B/L copy

2. 100% irrevocable LC at sight.

Shipment date: Within 15-20 days after advance payment or receipt of LC

Trade term: 1. FOB Shanghai port, China.

2. CIF Discharging port

Guarantee& Service: Mill Test Certificate is supplied with shipment, and Third Part Inspection is acceptable.

Packing: standard export packing (plastic package to prevent water or plywood case to strengthen package)

- Q: How do stainless steel bars resist scaling at high temperatures?

- Stainless steel bars resist scaling at high temperatures due to their unique composition and structure. Stainless steel is an alloy of iron, chromium, and other elements, which forms a protective layer of chromium oxide on the surface when exposed to air or moisture. This layer is extremely thin and tightly adheres to the steel, acting as a barrier against oxidation and scaling. The high chromium content in stainless steel bars, typically around 10-30%, is the key factor in their resistance to scaling. Chromium is highly reactive with oxygen and readily forms a stable oxide layer, even at elevated temperatures. This oxide layer prevents further oxidation of the underlying metal, effectively protecting the stainless steel from scaling. Additionally, stainless steel bars are often alloyed with other elements such as nickel, molybdenum, and titanium, which further enhance their high-temperature resistance. These alloying elements contribute to the formation of a more stable and dense oxide layer, making stainless steel bars even more resistant to scaling at extreme temperatures. Furthermore, stainless steel bars are typically manufactured with a fine-grained structure, which improves their resistance to scaling. The fine-grained structure provides a higher density of chromium oxide particles on the surface, increasing the protective effect against scaling. Overall, the combination of high chromium content, alloying elements, and fine-grained structure make stainless steel bars highly resistant to scaling at high temperatures. This resistance is crucial in various applications where the bars are exposed to extreme heat, such as in the construction of furnaces, boilers, and high-temperature processing equipment.

- Q: Are stainless steel bars suitable for the dairy industry?

- Stainless steel bars are an excellent choice for the dairy industry due to their hygienic properties, corrosion resistance, and durability. The dairy industry highly prefers stainless steel as it possesses these qualities. The ease of cleaning and maintenance of stainless steel bars makes them perfect for use in food processing and dairy production facilities where cleanliness and sanitation are crucial. Stainless steel's ability to resist corrosion ensures that it can withstand the tough chemicals and cleaning agents used in the dairy industry without rusting or deteriorating. Furthermore, stainless steel bars are sturdy and long-lasting, enabling them to bear heavy loads and provide structural support in various dairy applications. In summary, stainless steel bars offer a reliable and hygienic solution for the production and processing of dairy products, making them an exceptional choice for the dairy industry.

- Q: Can stainless steel bars be used in the transportation aftermarket?

- Yes, stainless steel bars can be used in the transportation aftermarket. Stainless steel is a durable and corrosion-resistant material, making it suitable for various applications in the transportation industry. It can be used in the production of components like handles, fasteners, and structural supports due to its strength and ability to withstand harsh conditions. Additionally, stainless steel's aesthetic appeal and low maintenance requirements make it a popular choice in the aftermarket, where quality and longevity are essential.

- Q: Are stainless steel bars suitable for bicycle frames?

- Yes, stainless steel bars are suitable for bicycle frames. Stainless steel is known for its corrosion resistance, which makes it ideal for cycling in various weather conditions, including wet and humid environments. Stainless steel frames also exhibit high durability and strength, providing a sturdy and reliable structure for the bicycle. Additionally, stainless steel has excellent fatigue resistance, meaning it can withstand repeated stress and strain without weakening or breaking. This makes it a suitable choice for riders who engage in intense or long-distance cycling. Moreover, stainless steel frames offer a smooth and comfortable ride due to their ability to dampen vibrations and absorb road shocks. Overall, stainless steel bars are a reliable and durable option for bicycle frames, ensuring longevity and performance for cyclists.

- Q: How are stainless steel bars priced?

- Stainless steel bars are priced based on various factors including the current market demand, size and dimensions, grade and quality of stainless steel, and any additional processing or finishing required. Additionally, factors like quantity ordered, delivery location, and prevailing market conditions can also influence the pricing of stainless steel bars.

- Q: What are the safety precautions when working with stainless steel bars?

- When working with stainless steel bars, it is important to follow several safety precautions. Firstly, always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots to protect against cuts, burns, and potential falling objects. Additionally, ensure the work area is well-ventilated, as stainless steel can produce fumes when heated or welded. Proper handling techniques should be employed to prevent injuries, such as using lifting equipment for heavy bars and avoiding sharp edges. It is also essential to be aware of the potential for fire hazards, as stainless steel can generate sparks when cutting or grinding. Therefore, keep flammable materials away from the work area and have fire extinguishers readily available. Finally, regularly inspect tools and equipment for any defects or damage to maintain a safe working environment.

- Q: Can stainless steel bars be used in the manufacturing of distillation columns?

- Stainless steel bars are capable of being utilized in the production of distillation columns. Owing to its remarkable resistance to corrosion and impressive strength, stainless steel is a favored material for distillation columns. These columns are employed in a range of industries, such as chemical, pharmaceutical, and petroleum, with the aim of segregating and purifying different elements within a mixture. The utilization of stainless steel bars guarantees that the distillation column can endure the severe conditions and corrosive environments typically encountered in these sectors. Furthermore, the ease with which stainless steel bars can be shaped and welded enables the customization and construction of distillation columns to satisfy specific requirements.

- Q: What are the different sizes available for stainless steel bars?

- To meet a variety of industrial and commercial needs, there is a wide selection of sizes for stainless steel bars. These sizes usually encompass diameter, width, and length measurements. Regarding diameter, stainless steel bars can range from as little as 1/16 inch (1.59 mm) to as large as 24 inches (609.6 mm) or even larger in certain cases. The primary application and load-bearing capacity of the bar are often determined by its diameter. Smaller diameter bars are commonly used for small-scale purposes such as jewelry making or precision engineering, while larger diameter bars are more suitable for heavy-duty applications such as construction or structural components. Width is another crucial aspect when it comes to stainless steel bars. Width refers to the thickness or breadth of the bar and can vary significantly depending on the specific type of bar. Typical widths for stainless steel bars range from 1/8 inch (3.18 mm) to 12 inches (304.8 mm) or more. The desired strength, stability, and intended use of the final product usually dictate the selection of the bar's width. Lastly, the length of stainless steel bars can also vary greatly. Standard lengths are often 12 feet (3.66 meters) or 20 feet (6.1 meters). However, custom lengths can be obtained to accommodate specific project requirements. Longer bars are commonly used in construction or industrial applications, while shorter bars may be suitable for smaller projects or specialized applications. In conclusion, stainless steel bars are available in a wide range of sizes, encompassing various diameters, widths, and lengths, in order to cater to diverse industries and applications. The choice of size depends on the intended use, load-bearing capacity, and specific requirements of the project or application at hand.

- Q: Are stainless steel bars suitable for heat exchangers?

- Yes, stainless steel bars are suitable for heat exchangers. Stainless steel is a popular material choice for heat exchangers due to its excellent corrosion resistance, high temperature resistance, and durability. The alloying elements in stainless steel, such as chromium and nickel, provide superior resistance to oxidation and scaling at high temperatures, making it ideal for applications that involve heat transfer. Stainless steel bars can be used in the construction of heat exchanger tubes, plates, or fins, providing efficient heat transfer and long-lasting performance. Additionally, stainless steel bars can withstand high pressure and temperature differentials, making them suitable for a wide range of heat exchanger applications in various industries, including chemical, petrochemical, food processing, and power generation.

- Q: Can stainless steel bars be used in food processing plants?

- Yes, stainless steel bars can be used in food processing plants. Stainless steel is a popular choice for the construction of equipment and fixtures in food processing plants due to its many desirable properties. Stainless steel is corrosion resistant, which is crucial in an environment where food products and cleaning agents are present. It is also easy to clean and maintain, making it hygienic for use in food processing plants. Additionally, stainless steel is non-reactive, meaning it does not interact with food, preserving its taste and quality. Overall, stainless steel bars are a suitable material for use in food processing plants due to their durability, corrosion resistance, and hygienic properties.

Send your message to us

Stainless steel round bar, angle bar, flat bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords