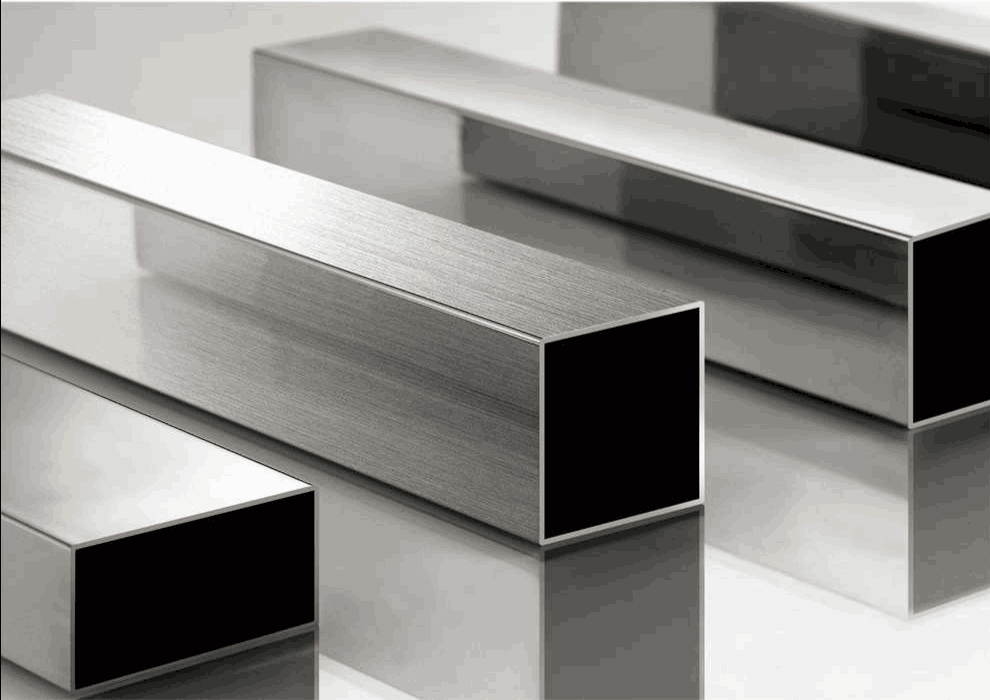

Stainless Steel Pipe Manufacturers in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

stainless steel pipe manufacturers

Material | 304:0cr18ni9, 0cr17ni8 201:1cr17mn6ni5n,1cr13mn9ni1n 316:0cr17ni12 or as customer’s request |

Size(round pipe) | 9.5, 12.7, 15.9, 17, 18, 19.1, 20, 21, 22.2, 23, 25.4, 28, 318, 35, 60, 63.5, 73, 76.2, 88.9, 101.6, 114.3, 127, 133, 59, 168, 219 mm or customized |

Size (square pipe) | 10×10,12×12,18×18,23×23,38×38,50×50,70×70,100×100,20×10,23×10,24×12,25×13,36×23, 40×20,50×20,60×15,75×45,80×60,95×45,100×60,150×100 mm or customized |

Size (oval pipe) | 30×15,80×40 mm os customized |

Thickness | 0.24-3 mm |

Length | 6m or according to customer’s request |

Outer diameter | 6.35-219mm |

Tolerance | Outer diameter :±0.2mm |

Thickness :±0.02mm | |

Length :±0.5mm | |

Process method | Code drawn, annealed with nitrogen protection, ultrasonic,automatic shape, polished |

Finishing | A: sanded B: 400#-600# mirror C: hairline brushed D: TIN titanlum E : HL brushed & mirror (two kinds of finishing for one pipe) |

Chemical Composition | |||||||

Material | C | Si | Mn | P | S | Cr | Ni |

201 | ≤0.12 | ≤0.75 | 9.5-12.5 | ≤0.045 | ≤0.03 | 13-16 | 0.8-1.5 |

304 | ≤0.08 | ≤0.75 | ≤2.0 | ≤0.045 | ≤0.03 | 18-19 | 8-10 |

316 | ≤0.08 | ≤1.00 | ≤2.0 | ≤0.035 | ≤0.03 | 10-14 | 16.0-18.5 |

430 | ≤0.12 | ≤0.75 | ≤2.0 | ≤0.04 | ≤0.03 | 16-18 | ≤0.6 |

Square pipe and rectangle pipe

round pipe

PACK & DELIVERY

Packaging & Delivery of stainless steel pipe manufacturers

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

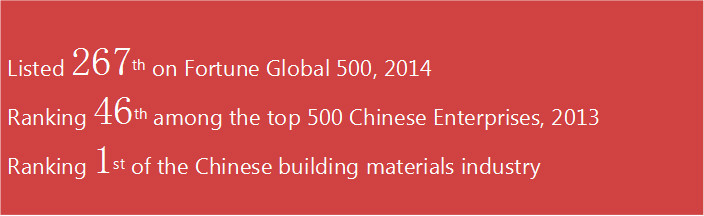

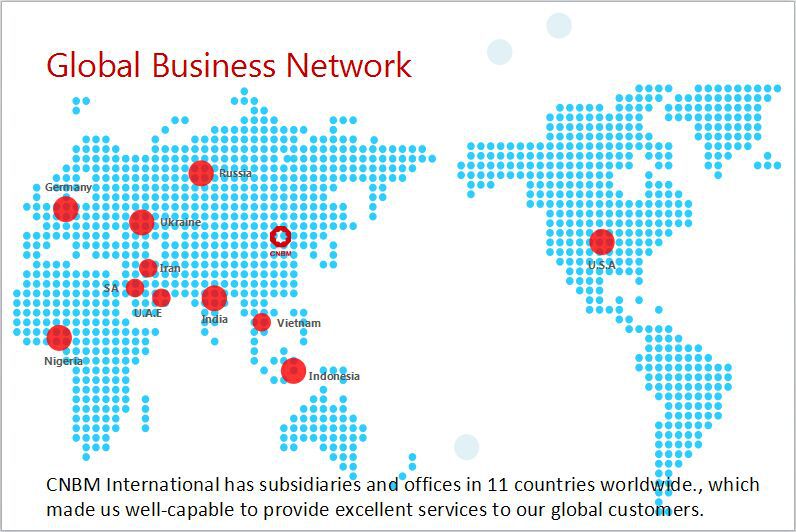

COMPANY INFORMATION

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

Client

Export Markets Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

F A Q

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories

- Q: Are stainless steel bars suitable for marine environments?

- Stainless steel bars are a perfect fit for marine environments due to their exceptional resistance to corrosion. This makes them an optimal selection for use in marine settings, where exposure to saltwater and high humidity levels can lead to corrosion and rusting in alternative materials. In marine environments, stainless steel bars exhibit exceptional resistance to pitting and crevice corrosion. Moreover, they possess high strength and durability, enabling them to withstand the demanding conditions and extreme weather typically found in marine applications. Consequently, stainless steel bars are extensively employed in the fabrication of marine vessels, offshore platforms, and a variety of marine equipment.

- Q: Can stainless steel bars be passivated?

- Yes, stainless steel bars can be passivated. Passivation is a process that is commonly used to improve the corrosion resistance of stainless steel. It involves removing any contaminants, such as free iron or other impurities, from the surface of the stainless steel and then forming a protective oxide layer. This oxide layer acts as a barrier, preventing further corrosion and enhancing the overall durability of the stainless steel. Passivation is typically done using a chemical treatment or an electrochemical process, and it is commonly used in various industries, including construction, automotive, and medical.

- Q: Are stainless steel bars suitable for manufacturing valves?

- Yes, stainless steel bars are suitable for manufacturing valves. Stainless steel offers excellent corrosion resistance, durability, and strength, making it a preferred material for valve production. It can withstand high temperatures, pressure, and harsh environments commonly found in industrial applications. Additionally, stainless steel's hygienic properties make it ideal for use in the food and beverage, pharmaceutical, and chemical industries.

- Q: Are stainless steel bars suitable for the marine industry?

- Stainless steel bars are a perfect fit for the marine industry. Their exceptional corrosion resistance properties make them ideal for use in marine environments, where exposure to saltwater and harsh weather conditions is common. The presence of chromium in stainless steel creates a protective film on its surface, preventing corrosion. This reduces the need for frequent maintenance and replacement, making stainless steel bars a cost-effective option for the marine industry. Moreover, stainless steel bars possess high strength and durability, which are crucial requirements for marine applications. They can withstand extreme temperatures, pressure, and mechanical stress, making them suitable for various marine structures like shipbuilding, offshore platforms, and marine equipment. Stainless steel bars also have an appealing aesthetic, making them popular in marine architectural designs. They can be easily polished, creating a sleek and visually pleasing appearance that enhances the overall look of marine structures and vessels. Furthermore, stainless steel bars require minimal maintenance. They do not need to be painted or coated to protect against corrosion, unlike other materials commonly used in the marine industry. This reduces the need for frequent inspections and touch-ups, saving time and resources. In conclusion, stainless steel bars are highly suitable for the marine industry due to their corrosion resistance, high strength, durability, aesthetic appeal, and low maintenance requirements. Their ability to withstand harsh marine environments and provide long-term performance makes them an excellent choice for various marine applications.

- Q: What are the different shapes and sizes of stainless steel bars available?

- Stainless steel bars are available in various shapes and sizes, including round, square, hexagonal, and flat bars. The round bars typically range from 1/4 inch to 12 inches in diameter, while the square and hexagonal bars can vary from 1/4 inch to 4 inches. Flat bars come in different widths and thicknesses, ranging from 1/8 inch to 6 inches. These diverse shapes and sizes allow stainless steel bars to be used in a wide range of applications across industries.

- Q: What are the different types of surface finishes for stainless steel bars?

- There are several types of surface finishes for stainless steel bars, including mill finish, brushed finish, polished finish, and satin finish. The mill finish is the standard finish and has a dull appearance. Brushed finish creates a textured look with parallel lines. Polished finish provides a mirror-like shine, while satin finish offers a smooth, matte appearance.

- Q: What are the different surface treatments available for stainless steel square bars?

- Stainless steel square bars can undergo various surface treatments, each offering unique advantages and enhancing the overall look and durability of the material. 1. Achieving a polished finish involves using abrasive materials to create a smooth and reflective surface on the stainless steel square bar. This treatment not only provides a high level of shine but also enhances the material's aesthetic appeal. Moreover, polished finishes offer improved corrosion resistance and ease of cleaning. 2. A brushed finish, on the other hand, creates a textured appearance by brushing the surface of the stainless steel square bar. This treatment involves using a wire brush or abrasive material to create parallel lines on the surface. The brushed finish offers a more matte appearance compared to polished finishes and helps to conceal any minor scratches or imperfections that may occur over time. 3. Bead blast finish involves propelling small glass beads or other abrasive materials onto the surface of the stainless steel square bar at high speed. This treatment creates a uniform matte appearance and helps to eliminate any surface contaminants or oxidation. Bead blast finishes are commonly applied in architectural or industrial settings where a non-reflective surface is desired. 4. PVD coating is a technique in which a thin layer of material is deposited onto the stainless steel square bar through a vacuum process. This coating enhances the material's appearance by offering a wide range of colors and finishes, such as gold, black, or bronze. PVD coatings also provide additional protection against wear, corrosion, and scratching. 5. Passivation is a chemical treatment used to remove any free iron or iron oxide from the surface of the stainless steel square bar. This process helps to enhance the material's corrosion resistance by creating a protective oxide layer on the surface. Passivation is typically carried out using nitric acid or citric acid solutions. In conclusion, the choice of surface treatment for stainless steel square bars depends on specific application requirements, desired appearance, and level of corrosion resistance needed. It is crucial to consider factors like durability, maintenance, and cost when selecting the appropriate surface treatment for stainless steel square bars.

- Q: Can stainless steel bars be used in storage tanks?

- Yes, stainless steel bars can be used in storage tanks. Stainless steel offers excellent corrosion resistance, durability, and strength, making it a suitable material for constructing storage tanks that need to store various substances, including liquids and gases.

- Q: What are the different surface coating techniques for stainless steel bars?

- There are several surface coating techniques available for stainless steel bars, depending on the desired outcome and application. Some of the commonly used techniques include: 1. Passivation: This technique involves treating the stainless steel surface with a chemical solution to remove any impurities or contaminants that may have been introduced during fabrication. Passivation helps to enhance the corrosion resistance of the stainless steel bars and improve their appearance. 2. Electroplating: Electroplating is a process that involves immersing the stainless steel bars in an electrolyte solution and applying an electric current to deposit a layer of metal onto the surface. This technique is commonly used to add a layer of chrome, nickel, or other metals to enhance the appearance, increase corrosion resistance, or improve wear resistance. 3. PVD (Physical Vapor Deposition) Coating: PVD coating is a vacuum deposition technique that involves vaporizing a solid metal or alloy and depositing it onto the stainless steel surface. This technique can produce thin films of various colors and finishes, such as gold, black, or bronze, providing decorative and functional benefits like improved hardness, wear resistance, and reduced friction. 4. Powder Coating: Powder coating involves applying a dry powder onto the stainless steel surface and then heating it to form a durable, protective layer. This technique offers a wide range of colors and finishes, as well as excellent corrosion and weather resistance. Powder coating is often used for outdoor applications where durability and aesthetics are paramount. 5. Anodizing: Anodizing is a process commonly used on aluminum, but it can also be applied to stainless steel. It involves creating an oxide layer on the surface through an electrochemical reaction. The resulting layer provides enhanced corrosion resistance, improved hardness, and can be dyed to achieve various colors. 6. Organic Coatings: Organic coatings, such as paint or lacquer, can also be applied to stainless steel bars. These coatings provide aesthetic enhancement, corrosion protection, and resistance to chemicals, abrasion, and UV radiation. However, organic coatings may not be as durable as other techniques and may require periodic maintenance. These are just a few of the surface coating techniques available for stainless steel bars. Each technique has its own advantages and limitations, and the choice depends on the specific requirements of the application, such as corrosion resistance, aesthetics, durability, and cost-effectiveness.

- Q: What are the different types of stress corrosion cracking in stainless steel bars?

- There are several types of stress corrosion cracking (SCC) that can occur in stainless steel bars, each with its own distinct characteristics and mechanisms. 1. Chloride stress corrosion cracking (CSCC): This is the most common form of SCC in stainless steel bars. It occurs when the stainless steel is exposed to an environment containing chlorides, such as seawater or other corrosive solutions. Chlorides can penetrate the passive oxide layer on the stainless steel surface, leading to localized corrosion and cracking. 2. Hydrogen-induced stress corrosion cracking (HISCC): Hydrogen can cause SCC in stainless steel bars, especially in environments with high hydrogen concentration or when hydrogen is absorbed during processing or service. The presence of hydrogen can lead to the formation of internal cracks, which can propagate and cause failure of the material. 3. Sulfide stress corrosion cracking (SSC): This type of SCC occurs in environments rich in sulfides, such as sour oil and gas environments. Sulfides can react with the stainless steel, causing localized corrosion and cracking. SSC is particularly problematic in high-strength stainless steels used in the oil and gas industry. 4. Ammonia stress corrosion cracking (ASCC): Stainless steel bars exposed to ammonia-containing environments, such as fertilizers or refrigeration systems, can experience ASCC. The combination of ammonia and tensile stress can lead to cracking and failure of the material. 5. Acid stress corrosion cracking (ASCC): Certain acids, such as concentrated sulfuric acid or hydrochloric acid, can cause SCC in stainless steel bars. Acidic environments can attack the passive oxide layer on the stainless steel surface, leading to localized corrosion and cracking. It is important to note that the susceptibility to SCC varies depending on the specific grade and composition of the stainless steel as well as the environmental conditions. Proper material selection, design considerations, and preventive measures, such as corrosion-resistant coatings or inhibitors, can help mitigate the risk of SCC in stainless steel bars.

Send your message to us

Stainless Steel Pipe Manufacturers in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords