stainless steel ; round bar steel ;steel rod

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

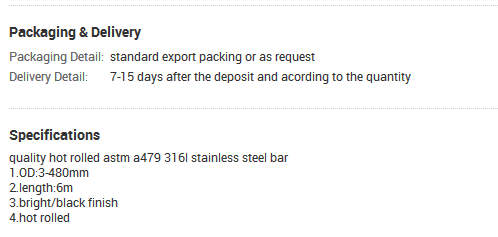

Product Description:

Stainless Steel Bar

Stainless Steel Round Bright Bar

Hot-rolled Stainless Steel Black Bar

Grades:201、202、301、302、303、304、316、316L、321 etc

Diameter (mm) | weight (kg/m) | Diameter (mm) | weight (kg/m) | Diameter (mm) | weight (kg/m) | Diameter (mm) | weight (kg/m) |

2 | 0.025 | 14 | 1.221 | 30 | 5.607 | 50 | 15.575 |

3 | 0.056 | 15 | 1.402 | 32 | 6.38 | 55 | 18.846 |

4 | 0.1 | 16 | 1.595 | 34 | 7.202 | 60 | 22.428 |

5 | 0.156 | 18 | 2.019 | 35 | 7.632 | 65 | 26.322 |

6 | 0.224 | 19 | 2.249 | 36 | 8.074 | 70 | 30.527 |

7 | 0.305 | 20 | 2.492 | 38 | 8.996 | 75 | 35.044 |

8 | 0.399 | 22 | 3.015 | 40 | 9.968 | 80 | 39.872 |

9 | 0.505 | 24 | 3.588 | 42 | 10.99 | 85 | 45.012 |

10 | 0.623 | 25 | 3.894 | 45 | 12.616 | 90 | 50.463 |

11 | 0.754 | 27 | 4.542 | 46 | 13.183 | 95 | 56.226 |

12 | 0.897 | 28 | 4.884 | 48 | 14.354 | 100 | 62.3 |

- Q: What is the modulus of elasticity of a steel round bar?

- The modulus of elasticity of a steel round bar typically ranges from 190 to 210 gigapascals (GPa).

- Q: What is the cost of steel round bars compared to other materials?

- The cost of steel round bars can vary depending on the specific type of steel and current market conditions. Generally, steel round bars tend to be more cost-effective compared to other materials such as aluminum or titanium, especially when considering their strength and durability. However, it is always recommended to compare prices and quality from different suppliers to get a more accurate understanding of the cost differences.

- Q: Can steel round bars be heat treated to enhance their properties?

- Steel round bars can undergo heat treatment to improve their properties. This process involves controlled heating and cooling to modify the microstructure of the steel, ultimately enhancing its mechanical properties like strength, hardness, toughness, and ductility. Various heat treatment methods can be employed based on the desired outcome. One commonly used method is quenching and tempering. This involves heating the steel to high temperatures, forming a uniform austenitic structure, then rapidly cooling it in oil or water to transform the austenite into a stronger structure called martensite. However, martensite can be brittle, so the steel is subsequently tempered by reheating it at lower temperatures to reduce brittleness while maintaining the desired hardness. Another method is annealing, where the steel is heated to a specific temperature and slowly cooled to relieve internal stresses and enhance ductility. This process also refines the grain structure of the steel, improving machinability and formability. Furthermore, there are other heat treatment methods like normalizing, stress relieving, and case hardening, each tailored to enhance specific properties of steel round bars. Overall, heat treatment is a versatile and effective technique for enhancing the properties of steel round bars, enabling them to meet specific requirements in industries such as manufacturing, construction, automotive, and aerospace.

- Q: Are steel round bars available in different diameters?

- Yes, steel round bars are available in a variety of diameters to suit different applications and requirements.

- Q: What is the hardness of a steel round bar?

- The hardness of a steel round bar can vary depending on the specific type of steel and the manufacturing process used. Steel is typically measured for hardness using the Rockwell hardness scale, which measures the depth of indentation caused by a specific load on a diamond or steel ball. Common hardness values for steel round bars can range from around 20 to 60 Rockwell C (HRC), with higher numbers indicating a harder material. However, it is important to note that the hardness of a steel round bar can also be influenced by factors such as heat treatment, alloying elements, and any surface treatments applied. Therefore, it is essential to consult the specific hardness specifications provided by the manufacturer or supplier to accurately determine the hardness of a steel round bar.

- Q: Are steel round bars suitable for marine applications?

- Yes, steel round bars are suitable for marine applications. Steel is known for its strength, durability, and corrosion resistance, making it a popular choice for various marine applications. Steel round bars are commonly used in the construction of marine structures, such as shipbuilding, offshore platforms, and marine equipment. The high tensile strength of steel allows it to withstand the harsh conditions of the marine environment, including the corrosive effects of saltwater. Additionally, steel can be easily fabricated and welded, making it a versatile material for marine applications. However, it is important to consider the specific requirements of the marine application and choose the appropriate type of steel round bar. Duplex stainless steel, for example, offers superior corrosion resistance compared to standard carbon steels and is often preferred for marine applications. It is also crucial to apply proper maintenance and protective coatings to ensure the longevity and performance of steel round bars in marine environments. Overall, steel round bars are a suitable choice for marine applications due to their strength, durability, and corrosion resistance. However, it is essential to select the right type of steel and implement proper maintenance practices to ensure optimal performance in the marine environment.

- Q: Are steel round bars resistant to impact?

- In general, steel round bars exhibit resistance against impacts. Steel is renowned for its remarkable strength and durability, rendering it highly impervious to forces and impacts. Additionally, the circular configuration of these bars aids in evenly dispersing the impact, thereby diminishing the likelihood of deformation or fracture. Nevertheless, it is crucial to acknowledge that the steel's resistance to impact may vary depending on the grade and quality, as well as the magnitude and characteristics of the impact force.

- Q: Can steel round bars be used for making mining equipment?

- Certainly! Mining equipment can indeed be made using steel round bars. These bars, owing to their exceptional strength, durability, and resistance to wear and tear, are widely utilized in the manufacturing process of various mining equipment. They are particularly suitable for applications that demand robust and heavy-duty machinery, such as drilling rigs, excavators, crushers, and conveyor systems employed in the mining industry. The adaptability of steel round bars enables them to be machined, welded, and shaped into diverse forms and sizes, thus facilitating the customization of mining equipment to cater to specific requirements. Moreover, steel round bars exhibit remarkable resilience in mining environments, enduring exposure to abrasive substances, extreme temperatures, and substantial loads.

- Q: What are the different grades of steel used for round bars?

- There are several different grades of steel that are commonly used for round bars. These grades vary in their composition and properties, making them suitable for different applications. Some of the most common grades of steel used for round bars include: 1. Mild Steel (Low Carbon Steel): This is the most basic and widely used grade of steel. It has a low carbon content, which makes it easy to work with and relatively inexpensive. Mild steel round bars are commonly used in construction, automotive, and general engineering applications. 2. Carbon Steel: This grade of steel contains higher levels of carbon than mild steel, giving it improved strength and hardness. Carbon steel round bars are often used in high-stress applications, such as structural components, axles, and shafts. 3. Alloy Steel: Alloy steel round bars are made by adding various alloying elements, such as chromium, nickel, or molybdenum, to the base steel. This enhances the strength, toughness, and corrosion resistance of the material. Alloy steel round bars are commonly used in aerospace, automotive, and machinery industries. 4. Stainless Steel: Stainless steel is a corrosion-resistant grade of steel that contains high levels of chromium. It is known for its excellent strength, durability, and resistance to rust and staining. Stainless steel round bars are widely used in the food industry, marine applications, and architectural components. 5. Tool Steel: Tool steel round bars are specifically designed to have high hardness, wear resistance, and heat resistance. They are commonly used in the manufacturing of cutting tools, dies, and molds. These are just a few examples of the different grades of steel used for round bars. Each grade offers unique properties and characteristics, allowing for a wide range of applications across various industries.

- Q: The diameter of 20 solid round steel bend into a circle, what machine bending?

- Gear type steel bar benderStructure: gear type steel bending machine mainly consists of several motors, gear reducer, work mechanism and electrical control system. It changed the traditional worm gear drive, and increased the angle automatic control mechanism and brake device.Operation principle: the gear type steel bar bender is driven by a motor with braking, which drives the working disc to rotate. The two inserting seats on the left and right of the working mechanism can be adjusted by the hand wheel without bending, and can be bent and bent with different specifications of the steel bar. The angle is controlled by several different institutions and primary angle limit pin with each other and realize. When the steel bar is bent to the preselected angle, the limit pin touches the travel switch, causes the motor to stop and reverse, recover to the original position, and complete the bending process of the steel bar. In addition, the electric control system also has the characteristics of inching, automatic state, two-way control, instantaneous braking, emergency stop, rapid system short circuit protection, motor overheat protection, etc..

Send your message to us

stainless steel ; round bar steel ;steel rod

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords