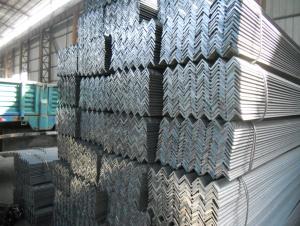

GB Standard Steel Round Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Steel Round Bar:

1. Standard: GB

2. Grade: Q345

3. Invoicing on theoretical weight or actual weight as customer’s request

4. Shape: Round bar, solid bar of steel with circular section

5. Technique: Hot rolled

Size:

| Size (mm) | Section Area (cm2) | Mass (Kg/m) |

| 13 | 132.665 | 1.04 |

| 14 | 153.86 | 1.21 |

Packaging & Delivery of Steel Round Bar:

Packaging Detail: Standard seaworthy packing or as customer required; all goods are packed in bundle with steel strips and shipped by break bulk vessel or container

Delivery Detail: 45 days

Trade terms: FOB, CFR, CIF or as customer required

MOQ: 25 tons per specification; we can negotiate the quantity if the specification is normal or we have stock of one specification.

Weight: The price invoicing on theoretical weight basis or actual weight basis depends on customer’s request.

Shipment: The shipment of bulk break or container is depends on customer’s request.

Documents given: Full set (3/3) of original clean on board bill of lading; Original signed commercial invoice, in 3 originals and 3 copies; Original packing list in 3 originals and 3 copies; Policy of insurance; Certificate of origin and what the target market needs.

* If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: Can steel round bars be used in the manufacturing of shafts?

- Yes, steel round bars can be used in the manufacturing of shafts. Steel round bars are often used as raw materials for shaft manufacturing due to their high strength, durability, and excellent mechanical properties. The round shape of the bar allows for easier machining and forming processes, making it suitable for creating shafts of various sizes and lengths. Additionally, steel round bars can be heat treated to enhance their hardness, strength, and wear resistance, further improving their suitability for shaft applications.

- Q: What are the different types of steel round bars used in the automotive drivetrain systems?

- There are several types of steel round bars commonly used in automotive drivetrain systems, including alloy steel, carbon steel, and stainless steel. These bars are chosen based on their specific properties and characteristics, such as strength, durability, and resistance to corrosion. The selection of the type of steel round bar depends on the specific application and requirements of the drivetrain system.

- Q: Are steel round bars suitable for the manufacturing of shafts?

- Yes, steel round bars are suitable for the manufacturing of shafts. Steel round bars are known for their strength, durability, and ability to withstand heavy loads and high rotational speeds, making them ideal for shaft applications. The round shape of the bar promotes uniform stress distribution, reducing the risk of failure or deformation. Additionally, steel round bars can be easily machined and heat-treated to achieve desired mechanical properties, such as hardness and toughness, further enhancing their suitability for shaft manufacturing. Overall, steel round bars offer the necessary characteristics required for shafts, making them a reliable and commonly used material in various industries.

- Q: Can steel round bars be used in the production of gears?

- Yes, steel round bars can be used in the production of gears. Steel round bars are commonly used as raw material for manufacturing gears due to their high strength, durability, and excellent mechanical properties. They can be machined, heat treated, and shaped into the desired gear profiles, making them suitable for various applications in industries such as automotive, machinery, and manufacturing.

- Q: Can steel round bars be used for making shock absorber components?

- Yes, steel round bars can be used for making shock absorber components. Steel is a common material choice for shock absorber components due to its strength, durability, and ability to withstand high levels of stress and impact. The round shape of the bars also allows for easy machining and fabrication of the necessary components.

- Q: Are steel round bars suitable for electrical conductivity?

- Steel round bars are not typically known for their electrical conductivity. Steel is a good conductor of heat but has relatively poor electrical conductivity compared to other metals such as copper or aluminum. This is because steel is primarily composed of iron, which is a poor conductor of electricity. However, the electrical conductivity of steel can be improved by adding certain alloying elements such as chromium or nickel. These alloying elements can enhance the electrical conductivity of steel, making it more suitable for specific applications where electrical conductivity is required. Nonetheless, if high electrical conductivity is a critical requirement, other materials like copper or aluminum are usually preferred over steel round bars.

- Q: What are the advantages of using precipitation-hardening steel round bars?

- Using precipitation-hardening steel round bars in various applications has several advantages. Firstly, these bars provide exceptional strength and hardness, making them suitable for industries that require robust and durable materials. The precipitation-hardening process involves heat treatment, which enhances the steel's strength and resistance to wear, deformation, and fatigue. Secondly, precipitation-hardening steel round bars exhibit excellent corrosion resistance. This makes them ideal for applications in marine environments or industries where exposure to harsh chemicals or corrosive substances is common. The steel's resistance to corrosion ensures the longevity and reliability of components or structures made from it. Another advantage is the versatility of these bars. They can be easily machined, welded, and forged, allowing for flexibility in design and fabrication processes. This makes them suitable for a wide range of applications, including aerospace, automotive, construction, and oil and gas industries. Furthermore, precipitation-hardening steel round bars offer good dimensional stability. Their low rates of thermal expansion mean they retain their shape and size even under extreme temperature variations. This characteristic is particularly important in precision engineering or tool manufacturing, where dimensional accuracy and stability are crucial. Lastly, the availability of a wide range of grades and sizes of precipitation-hardening steel round bars makes it easier to find the most suitable option for specific requirements. Different grades offer varying levels of strength, toughness, and corrosion resistance, allowing for tailored solutions to meet different application needs. Overall, the advantages of using precipitation-hardening steel round bars include exceptional strength, corrosion resistance, versatility, dimensional stability, and availability in various grades. These advantages make them the preferred choice for many industries requiring high-performance and durable materials.

- Q: How are steel round bars measured?

- The measurement of steel round bars is typically based on their diameter. The diameter is determined by measuring the distance across the widest part of the bar, usually in millimeters or inches. It should be emphasized that the diameter measurement is taken at the round bar's greatest cross-section, which is the distance across its center point. This measurement plays a crucial role in different applications as it assists in determining the strength, stability, and load-bearing capacity of the steel round bar.

- Q: Can steel round bars be used for decorative purposes?

- Indeed, decorative purposes can be served by steel round bars. When utilized in diverse architectural and interior design ventures, they contribute a contemporary and industrial appeal. By shaping, bending, and welding steel round bars, one can fashion exclusive and attention-grabbing items like furniture, sculptures, railings, and decorative accents. Their polished and metallic look harmonizes with various styles and design motifs, rendering them a versatile option for embellishment. Moreover, the durability and longevity of steel round bars guarantee that these decorative elements will endure the passage of time.

- Q: What are the different types of steel used to make round bars?

- The production of round bars involves the utilization of various types of steel. The selection of steel depends on the desired characteristics and applications of the round bars. Carbon steel is a commonly utilized steel for round bars due to its remarkable strength and durability. It finds extensive use in construction, machinery, and automotive components, where a sturdy and inflexible material is required. Stainless steel is another type of steel employed for round bars. It is renowned for its ability to resist corrosion and withstand high temperatures. Applications that necessitate resistance to moisture, chemicals, and heat, such as food processing equipment, medical devices, and architectural structures, often employ stainless steel. Alloy steel, which is formed by combining iron with other elements like manganese, chromium, and nickel, is also used for round bars. This blending enhances its properties, resulting in improved strength, hardness, and resistance to wear and tear. Aerospace components, automotive parts, and machinery often employ alloy steel round bars due to their high strength and toughness. Tool steel, designed specifically for the production of tools and dies, is another type of steel used for round bars. It is renowned for its high hardness, wear resistance, and ability to maintain a sharp cutting edge. Tool steel round bars are commonly employed in applications involving cutting, shaping, and forming, such as drills, punches, and molds. In conclusion, the choice of steel for round bars is determined by specific application requirements, including factors such as strength, corrosion resistance, heat resistance, and wear resistance.

Send your message to us

GB Standard Steel Round Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords