Low Carbon Steel C10/C15/C22/C25 Round Bars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Low Carbon Steel C10/C15/C22/C25 Round Bars

Product Description

1, Diameter: 8mm-250mm rounds

5mm-9mm rods

2, Length: 2m, 3m, 5.8m, 6m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black, Polished, Galvanized

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

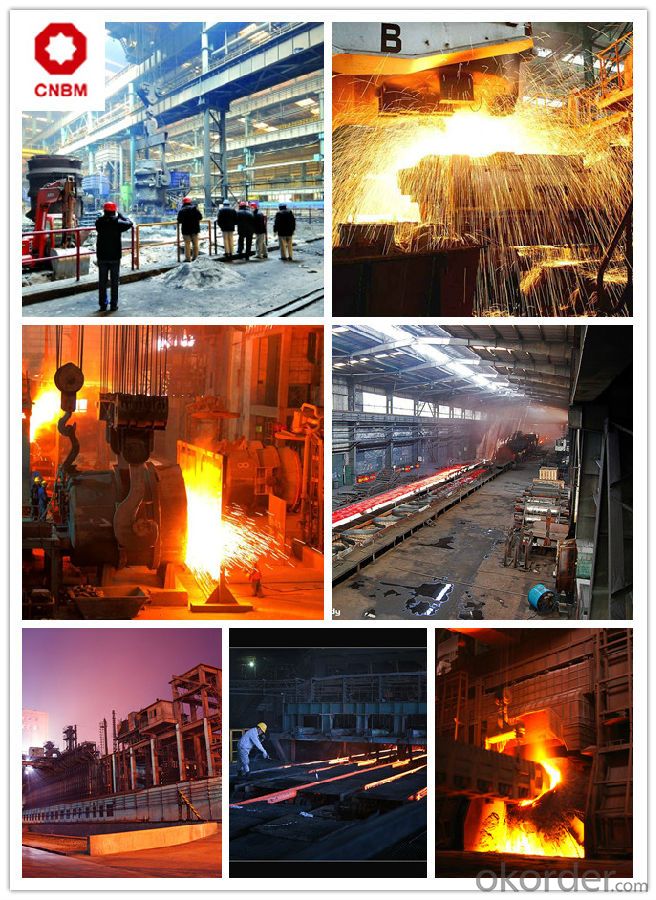

Products Show

Product Overviews

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 |

GB/SAE/JIS/DIN

|

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

Application

| Carbon Steel | Mold bottom, Plastic mold, Construction machinery parts Automobile parts, Security grills, Screens, Construction |

| Bearing Steel | Aerospace, Navigation, Nuclear energy, Chemical industry Electronic information, Petrochemical, Instrument and meter Transportation |

| Cr-Mo Steel | Mechanism & Fasteners gear, Stressed components for vehicles Engines and machines, Parts of larger cross-section |

| Gear Steel | All kinds of gears, Statically and dynamically stressed component for vehicles Engines and machine, Larger cross-section parts, Crankshafts |

Work Shop

Company Information

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: Are steel round bars suitable for high-pressure applications?

- Yes, steel round bars are often suitable for high-pressure applications. Steel is known for its strength and durability, making it an ideal material for withstanding high pressure. Round bars, in particular, offer excellent tensile strength and resistance to deformation, making them suitable for use in high-pressure environments such as hydraulic systems, oil and gas pipelines, and structural applications. Additionally, steel round bars can be manufactured to meet specific strength and hardness requirements, further enhancing their suitability for high-pressure applications. However, it is important to consider the specific requirements of the application and consult with an engineer or industry expert to ensure the appropriate grade and size of steel round bar is selected for optimal performance and safety.

- Q: Are steel round bars suitable for bearing applications?

- In general, steel round bars are suitable for bearing applications. Steel possesses qualities such as strength, durability, and resistance to wear and tear, which make it an ideal material for bearing purposes. Manufacturers often utilize steel round bars in the production of bearings because they have the ability to carry heavy loads and endure rotational forces. Furthermore, steel round bars can undergo heat treatment to increase their hardness and enhance their resistance to friction and corrosion, making them even more suitable for bearing applications. Nevertheless, it is crucial to take into account the specific requirements and conditions of the bearing application to ensure that the chosen steel round bars meet the necessary standards and specifications.

- Q: Can steel round bars be used for hydraulic applications?

- Yes, steel round bars can be used for hydraulic applications. Steel round bars offer high strength and durability, making them suitable for use in hydraulic systems that require robust components to handle high pressures and loads. Additionally, steel round bars can be easily machined and welded to meet specific hydraulic application requirements.

- Q: What is the difference between a cold-drawn and a centerless ground steel round bar?

- Both cold-drawn and centerless ground steel round bars are distinct types of steel bars that have undergone different manufacturing processes, leading to varied characteristics and properties. To produce cold-drawn steel round bars, a hot-rolled or annealed steel bar is pulled through a die, decreasing its diameter and increasing its length. This procedure enhances the steel's mechanical properties, making it stronger, more precise in dimensions, and possessing a smoother surface finish. Cold-drawn bars exhibit superior tensile strength, improved surface finish, and tighter dimensional tolerances compared to hot-rolled bars. They are frequently employed in applications that necessitate precision and strength, such as automotive components, machinery parts, and construction materials. On the contrary, centerless ground steel round bars are created by passing a cylindrical steel bar through a grinding machine without the need for centers or support. This grinding process eliminates surface imperfections and deviations in diameter, resulting in a precise and smooth finish. Centerless ground bars offer exceptional dimensional accuracy, surface finish, and roundness. They are commonly utilized in applications where precision and tight tolerances are crucial, such as in the production of bearings, shafts, and hydraulic cylinders. In conclusion, the primary distinction between a cold-drawn steel round bar and a centerless ground steel round bar lies in the manufacturing process and the resultant properties. Cold-drawn bars are formed by pulling the steel through a die, leading to enhanced mechanical properties, tighter tolerances, and a smoother surface finish. Centerless ground bars are produced by grinding the steel to enhance dimensional accuracy, roundness, and surface finish. Both types of bars possess their own advantages and are suitable for different applications based on the required precision, strength, and surface finish.

- Q: Can steel round bars be used in the production of electrical equipment?

- Steel round bars are capable of being utilized in the production of electrical equipment. Steel possesses a multitude of properties that render it suitable for various applications, including electrical equipment. Components such as shafts, connectors, and structural supports within electrical equipment can be manufactured using steel round bars. The reliability of steel is derived from its strength and durability, enabling it to withstand the mechanical stresses and environmental conditions that electrical equipment may encounter. Moreover, steel offers favorable electrical conductivity and magnetic properties, crucial characteristics for specific electrical components. Nevertheless, it is important to acknowledge that steel round bars may necessitate additional processes like machining, heat treatment, or surface finishing in order to meet specific requirements for the production of electrical equipment.

- Q: Can steel round bars be used for making gears or sprockets?

- Yes, steel round bars can be used for making gears or sprockets. Steel is a commonly used material in gear and sprocket manufacturing due to its high strength, durability, and resistance to wear and tear. Steel round bars can be machined or forged into the desired shape and then cut, drilled, or milled to create the necessary teeth or grooves required for gear or sprocket functionality. The specific type of steel and its heat treatment can be chosen based on the application requirements, such as load capacity, speed, and environmental conditions. Overall, steel round bars are a versatile and reliable choice for manufacturing gears and sprockets.

- Q: How do steel round bars compare to stainless steel round bars?

- Steel round bars and stainless steel round bars have some key differences that make them suitable for different applications. One of the main differences between steel and stainless steel round bars is their composition. Steel is primarily made of iron, with small amounts of carbon and other elements. Stainless steel, on the other hand, is an alloy composed of iron, chromium, and often other elements like nickel or molybdenum. This composition gives stainless steel its unique properties, such as corrosion resistance. In terms of strength, both steel and stainless steel round bars can be manufactured to have high tensile strength. However, stainless steel generally has higher tensile strength compared to regular steel, making it more suitable for applications that require additional strength and durability. Another important difference is their resistance to corrosion. Stainless steel round bars have excellent corrosion resistance due to the presence of chromium in their composition. This makes them ideal for applications where they will be exposed to moisture, chemicals, or other corrosive environments. Steel round bars, on the other hand, are more susceptible to rust and corrosion and may require additional protective coatings in such environments. In terms of cost, steel round bars are generally more affordable compared to stainless steel round bars. The higher cost of stainless steel is due to its unique properties and the additional alloying elements required in its production. Both steel and stainless steel round bars have their own advantages and applications. Steel round bars are commonly used in construction, manufacturing, and general-purpose applications where corrosion resistance is not a primary concern. Stainless steel round bars, on the other hand, find extensive use in industries such as food processing, chemical processing, medical equipment, and marine applications, where corrosion resistance is crucial. In summary, the choice between steel round bars and stainless steel round bars depends on the specific requirements of the application. Steel round bars are more affordable but may require additional corrosion protection, while stainless steel round bars offer superior corrosion resistance and strength.

- Q: What are the different types of steel round bars used in the manufacturing of cutting tools?

- There are several different types of steel round bars that are commonly used in the manufacturing of cutting tools. Some of the most commonly used types include: 1. High-Speed Steel (HSS): This type of steel is known for its excellent hardness, wear resistance, and ability to retain its cutting edge at high temperatures. HSS round bars are often used in the manufacturing of drills, end mills, and other cutting tools that are used for metalworking and high-speed applications. 2. Tool Steel: Tool steel round bars are widely used in the production of cutting tools due to their high strength, toughness, and resistance to wear and deformation. Different grades of tool steel, such as D2, A2, and O1, are chosen based on the specific application and requirements of the cutting tool. 3. Carbon Steel: Carbon steel round bars are commonly used in the manufacturing of cutting tools that are designed for softer materials, such as wood and plastics. Carbon steel offers good hardness and durability, making it suitable for a wide range of cutting applications. 4. Stainless Steel: Stainless steel round bars are often used in the manufacturing of cutting tools that require high corrosion resistance and strength. Stainless steel offers good durability, toughness, and edge retention, making it a popular choice for cutting tools used in the food industry, medical field, and other applications where cleanliness and hygiene are important. 5. Alloy Steel: Alloy steel round bars are made by adding various alloying elements, such as chromium, molybdenum, and vanadium, to improve the properties of the steel. Alloy steel offers enhanced hardness, strength, and wear resistance, making it suitable for cutting tools used in demanding applications, such as machining hardened materials and high-temperature cutting. It is important to choose the appropriate type of steel round bar based on the specific requirements of the cutting tool, including the material being cut, the desired cutting speed, and the expected operating conditions.

- Q: How do you determine the strength and hardness of a steel round bar?

- To determine the strength and hardness of a steel round bar, several tests and techniques can be employed. One of the most common methods is the tensile strength test. In this test, a sample of the steel round bar is subjected to a gradually increasing load until it reaches its breaking point. The maximum load it can withstand before breaking is recorded, which gives an indication of the bar's strength. Hardness testing is another crucial measure of steel round bar quality. The Rockwell hardness test is frequently used, where a diamond or tungsten carbide ball is pressed into the surface of the bar with a specific load. The depth of the indentation made by the ball is measured, and the hardness value is determined based on a standardized scale. Additionally, the Brinell hardness test can be utilized, where a hardened steel ball is pressed into the surface of the round bar with a specific load. The diameter of the indentation formed is measured, and the hardness is calculated based on the applied load and the size of the indentation. Furthermore, there are non-destructive techniques such as ultrasonic testing and magnetic particle inspection that can provide information about the internal structure, defects, and cracks within the steel round bar, thus indirectly indicating its strength and hardness. It is important to note that various factors, including the composition of the steel, its heat treatment, and the manufacturing process, can influence the strength and hardness of a round bar. Therefore, it is advisable to consult standards and specifications that define the expected properties for the specific type of steel round bar being tested.

- Q: What is the difference between gcr12 round bar and Cr12 round bar? Can it be used in general?

- The chromium content of the two is very different, and the range of application is different.

Send your message to us

Low Carbon Steel C10/C15/C22/C25 Round Bars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords