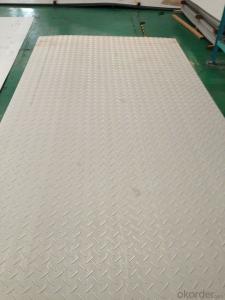

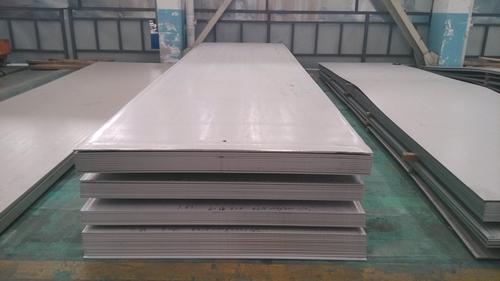

Stainless Steel 304 sheet with China manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless steel 304 sheet

Company advantage of stainless steel:

-Top Equipments, Leading In The Industry.

- Professional Team, Leading Innovation.

- Huge Supply Capacity Advantage, Timely and Effective Delivery.

- Modern Logistic, Fact and Convenient.

- Precise Manufacturing, Exquisite Products.

- Serve People, Create Value.

- Dimensional Network, Powerful Expansion.

Product Information of stainless steel sheet:

- Q: What is stainless steel pipe?

- Stainless steel pipe is a type of pipe made from an alloy of steel and chromium, with a high resistance to corrosion and staining. It is commonly used in various industries, including construction, automotive, and manufacturing, due to its durability and ability to withstand harsh environments.

- Q: Can stainless steel pipes be used for sewage systems?

- Yes, stainless steel pipes can be used for sewage systems. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for various applications, including sewage systems. Stainless steel pipes are capable of withstanding the harsh elements found in sewage, such as corrosive chemicals, high temperatures, and abrasive solids. Additionally, stainless steel pipes have a smooth surface, which minimizes the risk of clogs and blockages in the sewage system. This makes stainless steel pipes a reliable and long-lasting choice for sewage systems, ensuring efficient and effective waste disposal.

- Q: What is the difference between 304F and 316F stainless steel pipes?

- The main difference between 304F and 316F stainless steel pipes lies in their composition and characteristics. 304F stainless steel is an austenitic stainless steel, which means it contains high levels of chromium and nickel. It is known for its excellent corrosion resistance, weldability, and formability. This makes it a popular choice for various applications, including pipes used in industries such as food processing, chemical processing, and construction. However, 304F stainless steel is not as resistant to chloride corrosion as 316F stainless steel. On the other hand, 316F stainless steel is also an austenitic stainless steel, but it contains higher levels of chromium, nickel, and molybdenum compared to 304F stainless steel. The addition of molybdenum provides enhanced corrosion resistance, particularly against chlorides and other aggressive chemicals. This makes 316F stainless steel pipes suitable for more demanding applications, such as marine environments, where exposure to saltwater and corrosive chemicals is common. In summary, the main difference between 304F and 316F stainless steel pipes is their corrosion resistance. While both are austenitic stainless steels, 316F stainless steel offers superior resistance to chloride corrosion, making it a better choice for applications where corrosion resistance is critical.

- Q: Can stainless steel pipes be used for gas or oil transportation?

- Stainless steel pipes prove to be a viable option for transporting gas or oil due to their exceptional resistance to corrosion. Their ability to withstand corrosive fluids makes them highly suitable for this purpose. The pipes' resistance to rust, oxidation, and various types of corrosion ensures the pipes' longevity and integrity. Moreover, stainless steel pipes exhibit remarkable strength and durability, enabling them to endure high-pressure scenarios commonly encountered in gas or oil transportation. Additionally, the pipes' smooth inner surface guarantees low frictional resistance, facilitating efficient fluid flow. Nonetheless, when selecting stainless steel pipes for gas or oil transportation, it is crucial to consider factors like the stainless steel grade, compatibility with the specific gas or oil being transported, and adherence to relevant industry standards and regulations.

- Q: Are stainless steel pipes suitable for oil refineries?

- Yes, stainless steel pipes are suitable for use in oil refineries. Stainless steel is highly corrosion resistant, which is essential in an environment with high levels of corrosive substances such as crude oil and various chemicals used in refining processes. Stainless steel pipes are capable of withstanding high temperatures and pressures, making them ideal for transporting oil and gas within the refinery. Additionally, stainless steel pipes have low maintenance requirements and a long lifespan, reducing the need for frequent replacements and minimizing downtime. Overall, stainless steel pipes provide the durability, reliability, and resistance to corrosion necessary for the demanding conditions of oil refineries.

- Q: How much is one ton of stainless steel pipe?

- First of all, to determine the use of your stainless steel pipe, and now mainly with 304 stainless steel and 316L stainless steel,304 moderate price, good rust resistance, suitable for daily home decoration.

- Q: How do you prevent galling in stainless steel pipes?

- Galling, also known as cold welding, is a common issue in stainless steel pipes that can lead to damage and failure if not properly addressed. There are several steps that can be taken to prevent galling in stainless steel pipes: 1. Lubrication: Applying a suitable lubricant to the threaded connections can significantly reduce the risk of galling. Lubricants create a barrier between the mating surfaces, reducing friction and preventing the metal-to-metal contact that can lead to galling. It is important to use a lubricant specifically designed for stainless steel to ensure compatibility and effectiveness. 2. Proper pipe installation: Correct installation techniques play a crucial role in preventing galling. It is important to avoid over-tightening the connections as this can increase the risk of galling. Following the manufacturer's recommended torque specifications and using a calibrated torque wrench can help ensure proper installation without causing excessive stress on the threads. 3. Avoiding dissimilar metals: When connecting stainless steel pipes, it is important to avoid using dissimilar metals in the joint. Galvanic corrosion can occur when dissimilar metals come into contact, leading to galling. If dissimilar metals must be used, isolating gaskets or other insulating materials can be employed to prevent direct contact between the metals. 4. Surface finish: Maintaining a smooth surface finish on the threads can help reduce the risk of galling. Rough or damaged threads can create areas of high friction, increasing the likelihood of galling. Thoroughly inspecting and cleaning the threads before installation can help identify any imperfections that need to be addressed. 5. Material selection: Choosing the right grade of stainless steel is essential in preventing galling. Certain stainless steel alloys, such as 304 and 316, are more resistant to galling due to their higher nickel content. Consulting with a materials expert or referring to industry standards can help determine the most suitable stainless steel grade for a specific application. By implementing these preventive measures, the risk of galling in stainless steel pipes can be significantly reduced, ensuring the longevity and reliability of the piping system.

- Q: Can stainless steel pipes be bent or curved?

- Yes, stainless steel pipes can be bent or curved. Stainless steel is a versatile material that can be easily formed into various shapes, including bends and curves. This flexibility is due to its excellent ductility and high tensile strength. Stainless steel pipes are commonly bent or curved to fit specific design requirements in industries such as construction, automotive, and manufacturing. The bending process can be achieved through various methods, including hot bending, cold bending, and mandrel bending, depending on the desired shape and specifications. It is important to note that the bending or curving of stainless steel pipes should be done with proper equipment and expertise to ensure the integrity and quality of the pipe.

- Q: Can stainless steel pipes be used for gas pipelines?

- Yes, stainless steel pipes can be used for gas pipelines. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for transporting various types of gases, including natural gas and propane. Stainless steel pipes also have high tensile strength, which allows them to withstand high pressure and temperature conditions that are often encountered in gas pipelines. Additionally, stainless steel is non-reactive, meaning it does not react with the gases being transported, ensuring the integrity and safety of the pipeline system. Overall, stainless steel pipes are a reliable choice for gas pipelines due to their strength, corrosion resistance, and ability to handle high-pressure environments.

- Q: Are stainless steel pipes suitable for underground sewage systems?

- Certainly, underground sewage systems benefit greatly from the use of stainless steel pipes. Renowned for their resilience, robustness, and resistance to corrosion, stainless steel pipes prove to be an optimal selection for subterranean applications. With an extended lifespan, they can endure the demanding circumstances commonly encountered in sewage systems, such as exposure to moisture, chemicals, and fluctuating temperatures. Furthermore, the smooth interior surface of stainless steel pipes serves to prevent the accumulation of debris or waste, effectively decreasing the likelihood of clogs or obstructions. In summary, stainless steel pipes present a dependable and enduring solution for underground sewage systems.

Send your message to us

Stainless Steel 304 sheet with China manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords