Stainless Accessories System For Ceiling

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Suspension System) Description

Steel keel system:

Stud (vertical keel) :QC 70X40X0.60MM, 75X40X0.60MM

Track :QU 70x35x0.60MM

Steel keel system:

Include two parts: Accessories System for Ceiling and Accessories

Stainless Accessories system for wall partition:

1. Track ( Keep along the top(floor)): Style: QU75

Quantity or per M2(Square meters): 0.8m/M2

2. Stud ( Vertical Keel ) : Style: QC75

Quantity or per M2(Square meters): 2.5m/M2

3. Link-up keel: Style: DU38x12x1.00mm

Quantity or per M2(Square meters): 0.8m/M2, 3m/PC

4. Supporting block: Style: 75

Quantity or per M2(Square meters): 2pcs/M2

5. Paper Tape : B50XL45 45M/ROLL , WIDTH 50MM

Quantity or per M2(Square meters): 2m/M2

2,Main Features of the (Suspension System)

Stainless Accessories System for ceiling:

1. Main keel: Stype: DU38x12x1.00mm

Quantity or per M2(Square meters): 1.0m/M2, 3m/PC

2 Secondary keel: Style: DC50

Quantity or per M2(Square meters): 3.30m/M2

3. Second juncture: Style: DC50

Quantity or per M2(Square meters): 0.5pc/M2

4. Level fitting: Style: 50

Quantity or per M2(Square meters): 0.8pc/M2

5. Second rail: Style: 38back50

Quantity or per M2(Square meters): 2.5pcs/M2

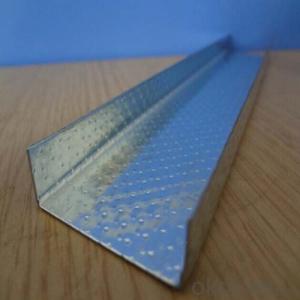

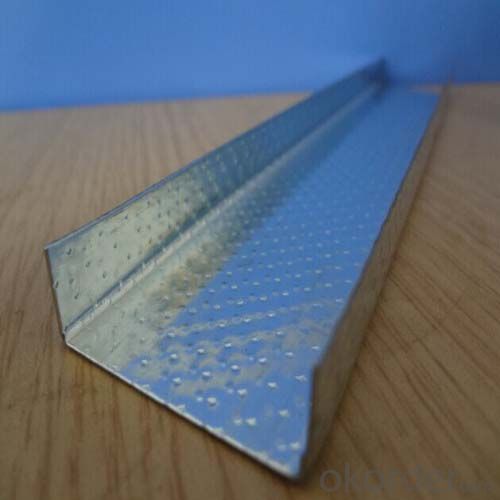

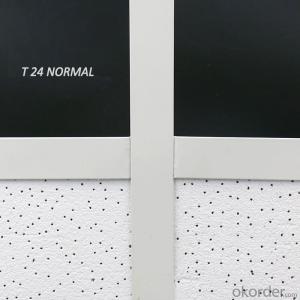

3,(Suspension System) Images

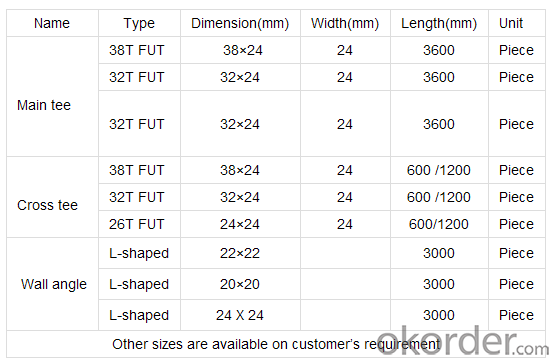

4,(Suspension System) Specification

5,FAQ of (Suspension System)

6. Light steel chief juncture: Style: DU38

Quantity or per M2(Square meters): 0.99pc/M2

7. Hanging rod: Stple: 8mm

Quantity or per M2(Square meters): 0.75m/M2, 3m/PC

8. Expansion bolt: Style: 8mm

Quantity or per M2(Square meters): 1pc/M2

9. Chief rail: Style: 38

Quantity or per M2(Square meters): 1pc/M2

10. Angle: Style: 15x20x30x0.50mm

Quantity or per M2(Square meters): 0.5m/M2

14. Connecting nut: Style: 6mm

Quantity or per M2(Square meters): 1pc/M2

- Q: Light steel keel to do a layer of gypsum board layer of nine layers of the wall how much money a square, the price is simple or double-sided?

- Home improvement living room ceiling works, gypsum board force does not need to add nine per cent board. Recommendation: direct use of light steel keel or wood keel and then add gypsum board just fine. Tip: If the shape is complex, available blockboard to take advantage of the keel on it

- Q: Light steel keel wall to withstand the number of wind load

- Light steel keel is a new type of building materials, with the development of China's modernization, in recent years has been widely used in hotels, terminals, passenger stations, stations, theaters, shopping malls, factories, office buildings, Interior decoration, ceiling and other places.

- Q: Light steel keel wall Why use gypsum board to do grass-roots level?

- Longgang wall: light steel keel is a new type of building materials, with the development of China's modernization, in recent years has been widely used in hotels, terminals, passenger stations, stations, theaters, shopping malls, factories, office buildings, old buildings Building renovation, interior decoration, roof and other places. Light steel keel wall with light weight, high strength, good fire resistance, versatility and easy installation characteristics, to adapt to shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, Easy to deformation and so on.

- Q: Can my light steel keel ceiling withstand the weight?

- According to your argument is no problem. Please feel free to use it

- Q: House decoration, the designer said the wall with light steel keel good, but the construction told me that this low efficiency can only be maintained for 4,5 years so I do not know in the end listen to who

- Mainly to see the use of the environment, if used in a humid environment, the life must be short, so the bathroom wall is best not to use light steel keel search.

- Q: How to fix the middle of the light steel keel to the roof and the ground, the keel has a joint?

- Keel fixation requires the use of expansion bolts fixed, but now many practices are directly linked with steel nails, so more convenient, the effect is almost, of course, is not good with expansion bolts. Top and bottom with 75 days keel. Then there are 75 vertical keels.

- Q: Light steel keel gypsum board partition wall construction practices and construction process What is the difference?

- The practice is to first play on the ground and shed on the corner keel must be vertical after the installation of the main keel times the keel installed in the plaster board plaster brush latex paint difference is stronger than the keel cost is higher than the wood keel

- Q: Light steel keel + gypsum board + surface brush latex paint partition wall per square meter offer is how much?

- Light steel keel about 12-13 yuan, enough to do a square, gypsum board per square 16 yuan (double) or so, paint workers wages about 25 yuan. / Square (package workers package material); Labor costs about 18 yuan, all offer for 75 yuan or so.

- Q: Light steel keel wall how much money a square

- Labor costs: light steel keel: 9 yuan / square, gypsum board 3 yuan / square (single) material costs: light steel keel (vertical spacing 400mm, three meters or less two feet through the heart): 20 yuan / square, 9.5 Mm thick plaster board: 7.5 yuan / square.

- Q: How much does it cost to use a light steel keel gypsum board?

- 15 square meters of the wall 15 * 65 = 925 + ordinary door 300 - 400 + installation door hand fee 120 = 1345-1445. But the square is too small, the general companies do not want to do, the fare back and forth have much money.

Send your message to us

Stainless Accessories System For Ceiling

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords