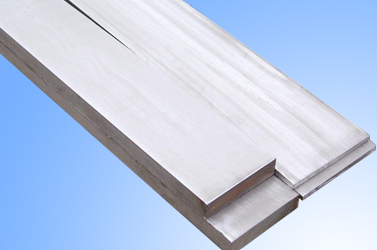

SS400 Q235B hot rolled steel flat bar Slitting flat bar galvanized flat bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 34000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

steel flat bar

steel flat bar thick : 2-20mm

steel flat bar wide : 10-870mm

steel flat bar length : 6m;9m;12m

Hot Rolled Flat Bar/ Slitting Flat Bar

1.We produce all the specifications of hot rolled flat steel and slitting flat bar

2.Lgare quantity in stock.

3.Best service.

flat bar

1.size: 20--150mm *2--20mm a36 flat bar

2.material:Q235 SS400 a36 flat bar

3.width:20-150mm

4.thickness:2--20mm

5.flat steel

1) Size: 2# - 150#

2) steel grade:Q195-Q235, ss400, s235 s275 s355 st37 st52.....

Packing:Suitable for export with hooks for easy unloading of material with bundle weightabout 2MT

Size | Width | Tolerance | Thickness | Tolerance |

20 | 20 | +0.5 -1 | 2--4 | +0.3 -0.5 |

22 | 22 | +0.5 -1 | 2--4 | +0.3 -0.5 |

25 | 25 | +0.5 -1 | 2--6 | +0.3 -0.5 |

28 | 28 | +0.5 -1 | 2--6 | +0.3 -0.5 |

30 | 30 | +0.5 -1 | 2--6 | +0.3 -0.5 |

32 | 32 | +0.5 -1 | 2--6 | +0.3 -0.5 |

35 | 35 | +0.5 -1 | 2--6 | +0.3 -0.5 |

40 | 40 | +0.5 -1 | 36 | +0.3 -0.5 |

45 | 45 | +0.5 -1 | 36 | +0.3 -0.5 |

50 | 50 | +0.5 -1 | 36 | +0.3 -0.5 |

55 | 55 | +0.6 -1.3 | 3--6 | +0.3 -0.5 |

60 | 60 | +0.6 -1.3 | 3--10 | +0.3 -0.5 |

65 | 65 | +0.6 -1.3 | 3--10 | +0.3 -0.5 |

70 | 70 | +0.6 -1.3 | 3--10 | +0.3 -0.5 |

75 | 75 | +0.6 -1.3 | 3--10 | +0.3 -0.5 |

80 | 80 | +0.9 -1.8 | 3--10 | +0.3 -0.5 |

85 | 85 | +0.9 -1.8 | 6--10 | +0.3 -0.5 |

90 | 90 | +0.9 -1.8 | 6--10 | +0.3 -0.5 |

95 | 95 | +0.9 -1.8 | 6--10 | +0.3 -0.5 |

100 | 100 | +0.9 -1.8 | 6--12 | +0.3 -0.5 |

105 | 105 | +1 -2 | 6--12 | +0.3 -0.5 |

110 | 110 | +1 -2 | 6--12 | +0.3 -0.5 |

120 | 120 | +1 -2 | 6--20 | +0.3 -0.5 |

125 | 125 | +1 -2 | 6--20 | +0.3 -0.5 |

130 | 130 | +1 -2 | 6--20 | +0.3 -0.5 |

140 | 140 | +1 -2 | 6--20 | +0.3 -0.5 |

150 | 150 | +1 -2 | 6--20 | +0.3 -0.5 |

- Q: What are the different packaging options available for steel flat bars?

- The different packaging options available for steel flat bars include bundled packaging, wooden crates, steel frames, or custom packaging based on specific customer requirements.

- Q: Can steel flat bars be used for making brackets or supports for audio/video equipment?

- Yes, steel flat bars can be used for making brackets or supports for audio/video equipment. Steel is a durable and strong material, making it suitable for supporting heavy equipment. The flat shape of the bars allows for easy attachment to walls, ceilings, or other surfaces. Additionally, steel flat bars can be easily cut and shaped to fit the specific dimensions and requirements of the equipment. They provide stability and can withstand the weight and stress of audio/video equipment, ensuring safe and secure mounting.

- Q: Can steel flat bars be used for making storage racks?

- Yes, steel flat bars can be used for making storage racks. Steel flat bars are strong and durable, making them suitable for supporting heavy loads in storage rack structures.

- Q: Are steel flat bars commonly used in the construction of government buildings?

- Yes, steel flat bars are commonly used in the construction of government buildings. Steel is a versatile and durable material that is widely used in the construction industry. Steel flat bars, specifically, are commonly used for structural support and reinforcement purposes. They are often used in the construction of columns, beams, and frames in government buildings, providing strength and stability to the overall structure. Additionally, steel flat bars are known for their resistance to fire, corrosion, and extreme weather conditions, making them a preferred choice for government buildings that require long-lasting and secure structures.

- Q: Construction of lightning protection ground galvanized flat steel approach, need to retest test? What's the test?

- Forged flat steel is a forged strip of steel with a rectangular cross section. Forging injustice can get certain shape and size and forgings, casting microstructure of the steel is remarkably improved, increase the density of steel; can change the distribution of the fiber structure, clear anisotropy, improve the mechanical properties of the metal, so that the strength and toughness of steel are improved; and it can be used to process the plastic lower high Shuogang and high alloy steel. Forged flat steel is mainly made of high quality alloy steel, mainly used as springs, tools and important mechanical parts.

- Q: What is the cost of steel flat bars?

- The price of steel flat bars may fluctuate due to several factors, including the steel grade, bar size, thickness, and the quantity being acquired. Typically, the cost of steel flat bars ranges between $10 and $50 per bar. Nevertheless, it is crucial to bear in mind that these figures are mere approximations and are subject to substantial variations depending on prevailing market conditions and individual suppliers. To obtain precise pricing information, it is advisable to reach out to local steel suppliers or consult online marketplaces for the latest updates.

- Q: Are steel flat bars suitable for making electrical machinery or equipment?

- Yes, steel flat bars can be suitable for making electrical machinery or equipment. Steel is a good conductor of electricity and has high strength and durability, making it a reliable material for various electrical applications. Additionally, steel can be easily shaped and fabricated to meet specific requirements, making it versatile for use in electrical machinery or equipment.

- Q: Are steel flat bars susceptible to warping or bending?

- Under certain conditions, steel flat bars may warp or bend. Although steel is a robust and long-lasting material, it is not entirely resistant to deformation. If exposed to excessive stress, heat, or mishandling, steel flat bars can undergo warping or bending. These instances can happen during manufacturing, transportation, or when subjected to heavy loads or extreme temperature fluctuations. To reduce the likelihood of warping or bending, it is essential to handle and store steel flat bars correctly, avoid excessive stress or heat, and adhere to the manufacturer's instructions for usage and maintenance.

- Q: What are the weight and load-bearing capacities of different steel flat bar sizes?

- Steel flat bars can have varying weight and load-bearing capacities depending on their size. Generally, the larger the flat bar, the greater its weight and load-bearing capacity. Below are some common sizes of steel flat bars and their approximate weight and load-bearing capacities: 1. For a thin flat bar that is 1/8 inch thick, it is typically used for lighter applications. Its weight can range from around 0.42 pounds per foot, and its load-bearing capacity is approximately 200 pounds per foot. 2. If the flat bar is slightly thicker at 1/4 inch, it can handle heavier loads. It typically weighs around 0.85 pounds per foot and has a load-bearing capacity of about 400 pounds per foot. 3. A thicker option is the 3/8 inch steel flat bar, which can support even greater loads. Its weight can range from around 1.27 pounds per foot, and its load-bearing capacity is approximately 600 pounds per foot. 4. Significantly thicker, the 1/2 inch steel flat bar is commonly used for heavy-duty applications. It weighs around 1.7 pounds per foot and has a load-bearing capacity of about 800 pounds per foot. 5. For extremely heavy loads, the 1 inch thick steel flat bar is suitable. It typically weighs around 3.4 pounds per foot and has a load-bearing capacity of approximately 1600 pounds per foot. It is important to note that these weight and load-bearing capacities are approximate and can vary based on the grade and quality of the steel used. Other factors such as the length and support conditions of the flat bar should also be considered when determining its maximum load-bearing capacity. It is advisable to consult professional engineers or refer to load tables provided by steel manufacturers for accurate and specific information on the weight and load-bearing capacities of steel flat bars.

- Q: What are the different types of corners available for steel flat bars?

- There are several different types of corners available for steel flat bars, including square corners, rounded corners, beveled corners, and chamfered corners. These variations in corner types provide different aesthetic and functional features, allowing for greater versatility in various applications.

Send your message to us

SS400 Q235B hot rolled steel flat bar Slitting flat bar galvanized flat bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 34000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords