Square Bars with Firm Sides for Middle Sizes in Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Square Bars with Firm Sides Description:

Square bars with firm sides is a bar with square shaped cross-section. It is special case of equal sides. Before steel products are sold on the market, the steel must first be processed into more functional pieces. Raw steel cannot be of use while in its pure form, thus it has to be cast into shape. The freshly made steel, square bars with firm sides is still in the form of a metal bar or rectangle. Small sizes of square bars with firm sides are used in ship building.

2. Main Features of Square Bars with Firm Sides:

• Grade: Q235

• Type: Mild carbon steel

• A quadrilateral with four equal sides and four right angles.

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

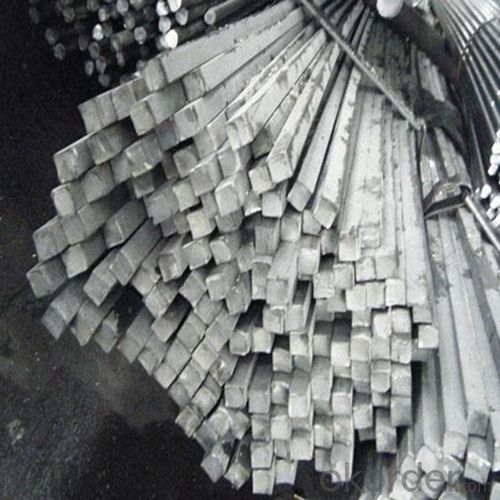

3. Square Bars with Firm Sides Images:

4. Square Bars with Firm Sides Specification:

Mechanical Properties | Grade | Steel diameter(mm) | |||

≤16 | 16~40 | 40~60 | 60~100 | ||

Yield Point Δs/MPa | Q195 | ≥195 | ≥185 | - | - |

Q235 | 235 | 225 | 215 | 205 | |

Tensile Strength | Q195 | 315~390 | |||

Q235 | 375~500 | ||||

Elongation δ5% | Q195 | ≥33 | ≥32 | - | - |

Q235 | 26 | 25 | 24 | 23 | |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①What is the main material?

There are two types of Square Bar, one is hot rolled square bar and other one is cold drawn square bar. Our principal products is hot rolled square bar. We dedicate to products with material Q195 and Q235. We offer products with high quality and low price.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: How do you use a steel square for leveling tasks?

- A steel square can be used for leveling tasks by placing it on a surface and checking if it is perfectly horizontal or vertical. This can be done by aligning the square's edges with the surface and using a bubble level or a plumb line to ensure accuracy. The steel square's straight edges and right angles make it a reliable tool for achieving level measurements.

- Q: Can a steel square be used for checking the levelness of a ceiling?

- No, a steel square is not suitable for checking the levelness of a ceiling. A level or a laser level would be a more appropriate tool for this purpose.

- Q: How do you use a steel square to mark out 30-degree angles?

- To use a steel square to mark out a 30-degree angle, first, align one edge of the square with the line you want to mark. Next, rotate the square until the 30-degree graduation on the scale aligns with the edge of the square. Finally, use a pencil or marking tool to trace along the other edge of the square, marking the desired 30-degree angle on your workpiece.

- Q: Are steel squares rust-resistant?

- Yes, steel squares are typically rust-resistant due to the protective coating or alloy composition used in their construction.

- Q: How do you use a steel square to determine the angle of a compound bevel and miter cut?

- To determine the angle of a compound bevel and miter cut using a steel square, the following steps can be followed: 1. Place the steel square on the edge of the material being cut, with the longer leg against the material surface and the shorter leg pointing upwards. 2. Adjust the position of the steel square so that the longer leg aligns with the material edge. 3. Once aligned, mark a line along the shorter leg of the square onto the material surface using a pencil or scribe. 4. Rotate the steel square to the desired angle for the compound bevel cut. This can be achieved by loosening the square's locking mechanism and pivoting it on the longer leg. 5. Align the longer leg with the previously marked line on the material when the square reaches the desired angle. 6. Mark a line along the longer leg of the square onto the material surface using a pencil or scribe. 7. The intersection of the two marked lines will indicate the angle of the compound bevel cut. 8. To determine the miter cut angle, measure the angle between the marked line along the longer leg of the square and the material edge. This measurement will guide the setting of your miter saw or miter gauge. By adhering to these steps, the angle of a compound bevel and miter cut can be accurately determined using a steel square, ensuring precise and exact cuts in woodworking or construction projects.

- Q: How do you make precise measurements with a steel square?

- To make precise measurements with a steel square, there are a few important steps to follow. First, ensure that the steel square is clean and free from any debris or rust that could affect its accuracy. Next, place the square on the surface or object you want to measure, making sure it sits flat and is aligned properly. To measure angles, use the 90-degree corner of the square as a reference point. Align one side of the square with the edge you want to measure, and read the angle measurement on the scale or protractor located on the other side of the square. Ensure that the square is perfectly aligned and there are no gaps or overlaps between the square and the edges. For measuring lengths, you can use the longer side of the square as a ruler. Align one end of the square with the starting point of the length you want to measure, and read the measurement on the scale or ruler located on the longer side. Again, ensure that the square is aligned correctly and there are no gaps or overlaps. To make more precise measurements, you can use a marking tool, such as a pencil or scribe, to mark the desired measurement directly on the object. This will help you maintain accuracy when transferring the measurement to other surfaces or during cutting or shaping processes. Overall, the key to making precise measurements with a steel square is to ensure proper alignment, eliminate any gaps or overlaps, and double-check all measurements before proceeding with any further steps.

- Q: Can a steel square be used for checking the squareness of window frames?

- Yes, a steel square can be used for checking the squareness of window frames. A steel square is a versatile tool commonly used in woodworking and construction to ensure accuracy and squareness. It consists of a steel blade with a 90-degree angle at one end and a handle at the other. By placing the steel square against the window frame, one can check if the corners are perfectly perpendicular or if there is any deviation from a right angle. If the steel square does not align properly with the corners, adjustments can be made to ensure the window frame is square before installation.

- Q: What are some common techniques for using a steel square in furniture making?

- Some common techniques for using a steel square in furniture making include checking for squareness and ensuring accurate angles when cutting and joining wood pieces. The steel square is often used as a guide for marking and measuring right angles, as well as for creating precise miter cuts. It can also be used to ensure accurate placement of hardware and components during assembly. Overall, the steel square is an essential tool for maintaining accuracy and precision in furniture making.

- Q: Are there any alternative tools to a steel square?

- Yes, there are several alternative tools to a steel square. Some commonly used alternatives include: 1. Speed Square: Also known as a rafter square, this tool has a triangular shape and is usually made of aluminum. It is specifically designed for measuring and marking angles, making it useful for carpentry and other construction projects. 2. Combination Square: This tool consists of a ruler and a pivoting head that can be set at any angle. It is widely used in woodworking and metalworking for measuring and marking straight lines, right angles, and various angles. 3. Framing Square: This square is larger than a steel square and is typically made of aluminum or steel. It is commonly used in construction for measuring and marking right angles, laying out stairs, and checking roof pitches. 4. Bevel Gauge: This tool is used for measuring and transferring angles. It consists of an adjustable blade and a handle, allowing it to be set at various angles. It is commonly used in woodworking and metalworking for creating precise angles. 5. Angle Finder: Also known as a protractor or angle gauge, this tool is used for measuring and transferring angles accurately. It typically consists of a round disc with a scale and a pivoting arm or blade. These alternative tools provide different functionalities and features, catering to specific needs in various industries. While a steel square is versatile and widely used, these alternatives offer additional options for specific tasks and angles.

- Q: Can a steel square be used for plumbing tasks?

- Yes, a steel square can be used for plumbing tasks. While a steel square is primarily used in carpentry for measuring and marking right angles, it can also be helpful in plumbing tasks. For example, it can be used to ensure that pipes are properly aligned and perpendicular to walls or floors. Additionally, it can be used to measure and mark cuts on pipes or other plumbing materials. However, it is important to note that there are specific tools designed for plumbing tasks, such as pipe wrenches and pipe cutters, which may be more suitable and efficient for certain plumbing jobs.

Send your message to us

Square Bars with Firm Sides for Middle Sizes in Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords