SPU-B Single Component Polyurethane Waterproof Coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single Component Polyurethane Waterproof Coating Introduction

Single-component moisture-curing pure polyurethane waterproof coating is a kind of liquid polymer waterproof material,

suitable for dry and wet base surface construction, solidified into tough and elastic, non-toxic and tasteless waterproof

film after coating. It is a new type of environmental friendly waterproof material without solvent.

Single Component Polyurethane Waterproof Coating Application

•Building roof

•Concrete

•Wall

•Water Tank Structure

•Floor(kitchen floor, bathroom floor ect)

•Underground Tunnel

•Sewerage Structure

•Movement Joint

•Wet Area, Pipes, Sewer & etc.

Single Component Polyurethane Waterproof Coating Advantage

1.water based and solvent based

2.Solid content above 80%

3.Durable performance, UV resistant, ageing-resistant,resistant high and low temperature,antifatigue, withstand constant immersion in water

4.Good splicing performance

5.Operate conveniently, low viscosity

6.Can splicing with concrete and many kinds board stuff

7.Will not change color after used

8.Apply for Roof,Swimming Pool,Tank and more

Single Component Polyurethane Waterproof Coating Specifications

NO. | Items | Ⅰ | Ⅱ |

1 | Tensile Strength MPa≥ | 1.9 | 2.45 |

2 | Elongation at Break %≥ | 550 | 450 |

3 | Tearing Strength N/mm≥ | 12 | 14 |

4 | Bend at Low Temperature°C≤ | -40 | |

5 | Unpermeability0.3MPa 30min | Impermeable | |

6 | Solids Content%≥ | 80 | |

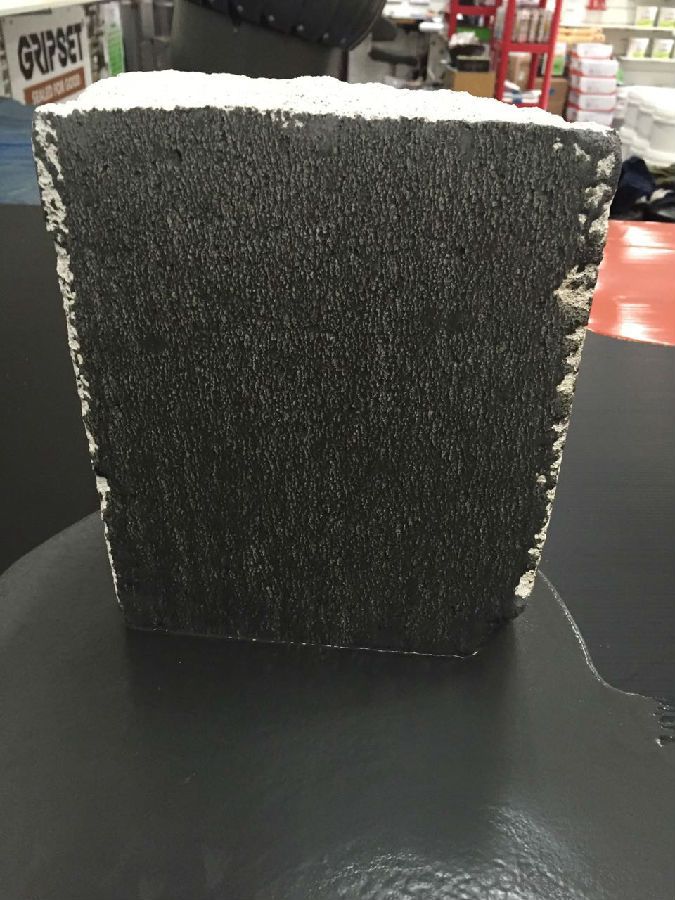

Single Component Polyurethane Waterproof Coating photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q: Cabinet is to buy finished products, or directly to the decoration company to do?

- Finished products to buy relatively easy to do some of the cabinet to do more solid material more assured because the plate is also a long-term environmental protection or woodworking directly do better feel that the company can quote their own under the woodworker comparison

- Q: What is the price of a waterproof window cover?

- 3, decorative panels Decorative panels are divided into paint-free panels and paint panels. Currently on the market, there are many window-free products, paint-free board is 5 mm density, the board pressure a layer of thin layer of color paper, due to the type of color paper, so there can be a lot of paint-free Color. Paint decorative panel is the surface of a layer of veneer plywood, there are many types, different wood has different colors. The benefits of window sets

- Q: Do you use the waterproof material on the building to be harmful to the human body?

- Your pores, the respiratory tract, the lungs, will be hurt, when young do not feel out, the consequences more powerful than smoking.

- Q: Oriental rain rain waterproof how to

- Strict selection and the pursuit of excellence in product performance of the East Rainbow waterproof coating long-term waterproof material in the market leading the main reason. In order to test product performance, the East Rainbow company to the product to the plateau, desert, alpine, high temperature and other areas for testing.

- Q: Can Henkel have water against him?

- Can ah ~ watered effect on the discount friends are high with the general are good, powder + pulp! Do not need to add water

- Q: Js waterproof coating without powder can brushing

- 2. Mixing and mixing: JS waterproof coating: cement = 1: 0.8 weight ratio of mixing, fully stirred to no particles, uniform mortar can be used; in the course of the application to adhere to intermittent mixing, to prevent layered deposition ;

- Q: Roof for the insulation, Master roof, using two waterproof construction program

- Fourth, the finished product protection 1, has been laid the membrane waterproof layer, should be taken to protect the facilities, is strictly prohibited in the waterproof layer on the construction operations and transportation, and should be timely to do the protective layer of the waterproof layer. 2, through the roof, wall waterproof layer at the pipeline, construction and after the completion of damage shall not damage. 3, deformation joints, water, etc., before the construction of waterproof layer, should be temporary closure, waterproof layer is completed, should be cleared to ensure that the tube, sewn smooth, to meet the use of function. 4, roof construction shall not pollute the walls, cornices and other finished products.

- Q: What is the car material so that the car can be waterproof, in the rain will not leak in?

- Engraving process car sticks A. knife engraving process: refers to the computer will be vector graphics input knife machine, the knife will be cut into a preset film shape, and then by hand will be different colors together Finished, and finally in the finished product posted on the surface of a layer of transparent transfer film, after the stickers to remove the stickers; due to knife car paste production process is complex, high cost of materials, currently only suitable for individual car and Che Youhui team Small customization

- Q: How can the toilet waterproof works fail?

- Can only do a new waterproof, and now have engaged in the base of the waterproof coating, the effect is very good. It is best to ask professionals to do their own difficult.

- Q: Roof sunscreen waterproof layer leakage, brush milk white plastic can solve it?

- Can not If the roof of a large area of ??leakage or a number of water leakage points, the first professional staff to check whether the cracks, the first to deal with leakage cracks in the roof covered with waterproof membrane, to enhance the waterproof effect, you can also shop On the insulation board, because the height of the insulation board in 20 cm or more, to achieve the protection of waterproof layer and thermal insulation of the double effect. Do not use the roof of the insulation board, you can consider the use of steel mesh mixed soil. Wall cracks caused by cracks in the water, under normal circumstances the professional construction team will use the basket, by the maintenance staff in the external wall construction. Large cracks can be used to plug the king, a small crack can be used to seal the glass glue, repair with a wall waterproofing agent, after spraying a few words on it.

Send your message to us

SPU-B Single Component Polyurethane Waterproof Coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords