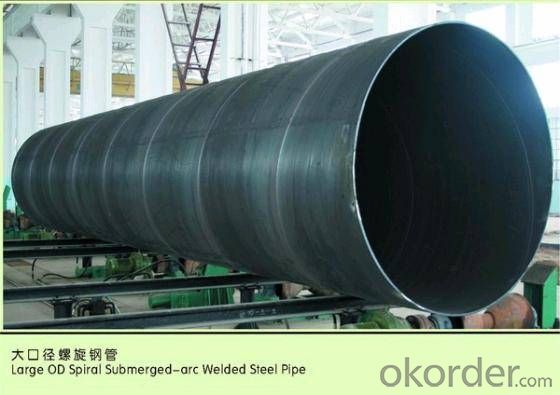

SPIRAL WELDED STEEL PIPE 32‘’ 48‘’CARBON

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail: | standard export packing or as customer's requirement |

Delivery Detail: | within 10 - 30 days |

Specifications

Spiral Welded Steel Pipes and Tubes

1.Material:Q195-Q235

2.Length:1-12m

3.WT:1.0-14mm

4.O.D.:20-273mm

Spiral Welded Steel Pipes and Tubes

Product Description:

1.Material : Q235,Q345,L245,L290,L360,L415,L450,L485,GrB,X42,46,X52,X56,X60,X65,X70,X80,X100

2,Standard: SY/T5037-2000,GB/T9711-2011,API Spec 5L PSL1/PSL2,ASTM A252\A53,ISO3183,DIN17172,EN10217,JIS G3457,AWWA C200,ASTM A139,ASTM A671,ASTM A672

3.Wall thickness: 3.0mm-30mm

4.Outer diameter: φ168mm-3020mm

5,Length: 5m-12m or as your requirement

6,Corrosion protection standard: DIN30670,DIN30671, AWWAC210, AWWA C203, SY/T0413-2002,SY/T0414-2002

7,Application: Oil, gas, natural gas, water pipe, thermal electricity pipe, steel structure engineering, etc

Q195-q345 Material Steel Pipe's Materials

Elements | Chemical Compsition% | Mechanical Property | ||||||

C% | Mn% | S% | P% | Si% | Yield Point (Mpa) | Tensile Strength(Mpa) | Elongation | |

Q195 | 0.06-0.12 | 0.25-0.50 | <0.050< span=""> | <0.045< span=""> | <0.030< span=""> | >195 | 315-430 | 32-33 |

Q215 | 0.09-0.15 | 0.25-0.55 | <0.05< span=""> | <0.045< span=""> | <0.030< span=""> | >215 | 335-450 | 26-31 |

Q235 | 0.12-0.20 | 0.30-0.70 | <0.045< span=""> | <0.045< span=""> | <0.030< span=""> | >235 | 375-500 | 24-26 |

Q345 | <0.20< span=""> | 1.0-1.6 | <0.040< span=""> | <0.040< span=""> | <0.55< span=""> | >345 | 470-630 | 21-22 |

Packaging & Delivery

Packaging Detail: | Normal exporting packing,in container or bulk vessel or as per clients' request |

Delivery Detail: | 2 months after confimed contract |

Specifications

Large Diameter API 5L X70 PSL2 LSAW Steel Pipe

Grade: X42, X46, X50, X52, X60, B, C

OD: 1.5"-28"

WT: SCH10-SCH160

Brand:TPCO

Large Diameter API 5L X70 PSL2 LSAW Steel Pipe

Specifications:

u Standard: API 5L

u Grade: B, C, X42, X46, X50, X52, X56, X60, X65, X70, X80

u OD: 1.5"-28"

u WT: SCH10-SCH160

u Length: 5-12m

u Ends Finish: plain end, bevel end, grooved end

u Surface Treatment: bare, black varnished, oiled finish, red color, anti-corrosion, 3PE, FBE or epoxy coating

u Technique: hot rolled or cold drawn

u Application: api 5l steel pipe for conveying oil, water, gas

u Invoicing: based on theoretical weight or actual weight

u Payment Terms: L/C at sight, T/T or Western Union

u Trade Terms: FOB, CFR, CIF

u Certification: ABS manufacturing assessment, ABS design assessment, API 5CT, API 5L, DNV manufacturer certificate, ISO9001 quality management system certificate, ISO14001 environment management system certificate, GB/T28001 occupational health and safety management system certificate, A1 class manufacturing license of special equipment certificate, CCS, GL, LR, SGS, TüV, PDE

- Q: Can steel pipes be used for water wells?

- Yes, steel pipes can be used for water wells. Steel pipes are commonly used for constructing water wells due to their durability, strength, and resistance to corrosion. They can withstand high water pressure and provide a reliable and long-lasting solution for accessing underground water sources.

- Q: Can steel pipes be used for wastewater disposal?

- Indeed, wastewater disposal can be accomplished using steel pipes. Owing to their robustness, strength, and corrosion resistance, steel pipes find widespread application in wastewater systems. They are capable of withstanding the substantial pressure and flow rates commonly encountered in wastewater scenarios, efficiently conveying it to treatment plants or other disposal sites. Moreover, steel pipes can be enhanced with coatings or linings that offer additional safeguard against corrosion or chemical reactions with the wastewater, further enhancing their durability and efficacy in wastewater disposal.

- Q: How are steel pipes used in offshore drilling platforms?

- Steel pipes are used in offshore drilling platforms to transport drilling fluids, such as mud and cement, from the drilling rig to the wellbore. These pipes are also used to extract oil and gas from the well by connecting the drilling rig to the subsea wellhead. Additionally, steel pipes provide structural support and stability to the drilling platform, ensuring safe and efficient operations in harsh offshore environments.

- Q: What does the diameter of a steel pipe project mean?

- Nominal surface meaning can be understood as a public address. It's as if everyone agreed to call something as a "devil", and he was the devil.Don't be confused by the numbers behind the nominal diameter. For example, DN50, this 50 is really close to the outer diameter or inside diameter of the steel tube, but DN50 is only a general model of the caliber of the national standard.

- Q: What is the outer diameter of the steel tube?

- The outer diameter refers to the maximum diameter including the thickness of the steel tube, the inner diameter is the length of the hollow part inside, and the outer diameter minus the inside diameter is the thickness of the steel pipe

- Q: How do you protect steel pipes from rusting?

- Steel pipes can be protected from rusting by applying a protective coating such as paint or zinc coating. Additionally, using corrosion inhibitors, maintaining proper drainage, and keeping the pipes dry can help prevent rust formation. Regular inspection and maintenance are also crucial to identify and address any potential issues before they escalate.

- Q: What are the different types of steel pipe supports?

- There are several types of steel pipe supports, including pipe hangers, pipe clamps, pipe saddles, pipe brackets, and pipe supports with rollers.

- Q: Galvanized steel pipe, PPR pipe, PE pipe, U-PVC pipe and HDPE double wall corrugated pipe and what is the difference between the characteristics of

- U-PVC tubes are hard poly vinyl pipes, because they contain chlorine, so they are mainly used in sewer pipes or electrical wiring;HDPE double wall corrugated pipe is a high-density polyethylene pipe, because of its excellent electrical insulation performance, now mainly used for distribution line arrangement.

- Q: What are the different types of valves used with steel pipes?

- There are several types of valves used with steel pipes, including ball valves, gate valves, globe valves, check valves, and butterfly valves.

- Q: Are steel pipes suitable for transporting chemicals?

- Yes, steel pipes are suitable for transporting chemicals. They are known for their durability, corrosion resistance, and high strength, which makes them ideal for carrying various chemicals safely and efficiently. Additionally, steel pipes can withstand high pressure and extreme temperatures, making them a reliable choice for transporting chemicals in industries such as oil and gas, petrochemicals, and manufacturing.

Send your message to us

SPIRAL WELDED STEEL PIPE 32‘’ 48‘’CARBON

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords