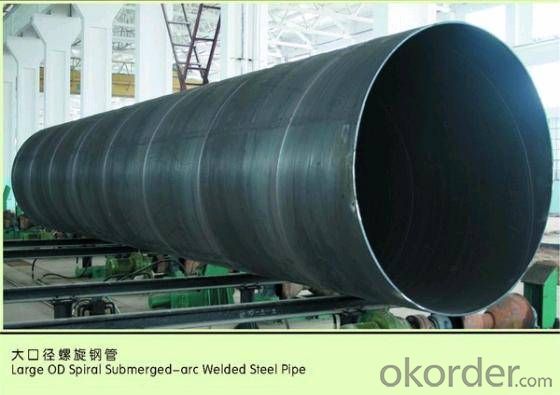

SPIRAL STEEL PIPE 60‘‘ ASTM API LARGE DIAMETER PIPE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail: | standard export packing or as customer's requirement |

Delivery Detail: | within 10 - 30 days |

Specifications

Spiral Welded Steel Pipes and Tubes

1.Material:Q195-Q235

2.Length:1-12m

3.WT:1.0-14mm

4.O.D.:20-273mm

Spiral Welded Steel Pipes and Tubes

Product Description:

1.Material : Q235,Q345,L245,L290,L360,L415,L450,L485,GrB,X42,46,X52,X56,X60,X65,X70,X80,X100

2,Standard: SY/T5037-2000,GB/T9711-2011,API Spec 5L PSL1/PSL2,ASTM A252\A53,ISO3183,DIN17172,EN10217,JIS G3457,AWWA C200,ASTM A139,ASTM A671,ASTM A672

3.Wall thickness: 3.0mm-30mm

4.Outer diameter: φ168mm-3020mm

5,Length: 5m-12m or as your requirement

6,Corrosion protection standard: DIN30670,DIN30671, AWWAC210, AWWA C203, SY/T0413-2002,SY/T0414-2002

7,Application: Oil, gas, natural gas, water pipe, thermal electricity pipe, steel structure engineering, etc

Q195-q345 Material Steel Pipe's Materials

Elements | Chemical Compsition% | Mechanical Property | ||||||

C% | Mn% | S% | P% | Si% | Yield Point (Mpa) | Tensile Strength(Mpa) | Elongation | |

Q195 | 0.06-0.12 | 0.25-0.50 | <0.050< span=""> | <0.045< span=""> | <0.030< span=""> | >195 | 315-430 | 32-33 |

Q215 | 0.09-0.15 | 0.25-0.55 | <0.05< span=""> | <0.045< span=""> | <0.030< span=""> | >215 | 335-450 | 26-31 |

Q235 | 0.12-0.20 | 0.30-0.70 | <0.045< span=""> | <0.045< span=""> | <0.030< span=""> | >235 | 375-500 | 24-26 |

Q345 | <0.20< span=""> | 1.0-1.6 | <0.040< span=""> | <0.040< span=""> | <0.55< span=""> | >345 | 470-630 | 21-22 |

- Q: Can steel pipes be used for underground gas distribution?

- Yes, steel pipes can be used for underground gas distribution. Steel pipes are commonly used for gas distribution as they are strong, durable, and can withstand high pressure. Additionally, steel pipes have excellent resistance to corrosion, which is crucial for underground installations. However, it is important to ensure proper coating and insulation to prevent any potential damage or leakage.

- Q: Can steel pipes be used for conveying sewage and wastewater?

- Yes, steel pipes can be used for conveying sewage and wastewater. Steel pipes are known for their strength, durability, and resistance to corrosion, making them suitable for transporting various types of fluids, including sewage and wastewater. Additionally, steel pipes can withstand high pressure and are capable of handling the abrasive and corrosive nature of sewage and wastewater, making them a reliable choice for such applications.

- Q: What materials are used in scaffolding pipes?

- Fastener warranty information should be complete, enter the site should be carried out after re sampling technology, performance shall be in accordance with provisions of the "GB15831" steel pipe scaffold fastener, before use should be individually selected, cracks, deformation, bolt slide wire is strictly prohibited.

- Q: What are the different types of steel pipe flanges?

- There are several types of steel pipe flanges, including slip-on flanges, weld neck flanges, socket weld flanges, threaded flanges, blind flanges, and lap joint flanges. Each type has unique features and is used in specific applications based on factors such as pressure ratings, pipe size, and end connections.

- Q: What are the different methods of pipe joining for steel pipes?

- The different methods of pipe joining for steel pipes include welding, threaded connections, flanged connections, and grooved connections. Welding involves melting the two ends of the pipes together to form a strong bond. Threaded connections involve screwing the pipes together using thread tape or sealants to create a tight seal. Flanged connections use flanges and bolts to join the pipes together, providing a secure and leak-proof connection. Grooved connections involve using grooved couplings and gaskets to connect the pipes, allowing for quick and easy installation.

- Q: What is the maximum temperature and pressure that steel pipes can withstand?

- The maximum temperature and pressure that steel pipes can handle differ based on the specific grade and type of steel utilized. Nevertheless, steel pipes generally have the ability to withstand high temperatures and pressures due to their robust and long-lasting nature. In applications where high temperatures are involved, like in steam or heat transfer systems, steel pipes can typically endure temperatures up to 1000 degrees Celsius (1832 degrees Fahrenheit) or even higher. It is important to note that the exact temperature limit may fluctuate depending on the steel's alloy composition and heat treatment. In terms of pressure, steel pipes are renowned for their exceptional strength and ability to resist internal and external pressure. The maximum pressure that steel pipes can handle will depend on factors such as pipe diameter, wall thickness, and material strength. In industrial applications, steel pipes can handle pressures ranging from a few hundred psi (pounds per square inch) to several thousand psi. To ensure the safe operation of steel pipes under high temperatures and pressures, it is vital to adhere to industry standards and guidelines, as well as conduct regular inspections and maintenance. Seeking advice from engineers and professionals experienced in steel pipe systems can provide more specific information regarding the maximum temperature and pressure limits for a particular steel pipe application.

- Q: How are steel pipes used in the telecommunications infrastructure?

- Steel pipes are used in the telecommunications infrastructure for various purposes such as underground cable installation, mounting antennas, and supporting communication towers. They provide durability, strength, and protection for the cables and equipment, ensuring reliable and efficient communication networks.

- Q: Can steel pipes be painted or coated?

- Certainly, steel pipes have the capability to undergo painting or coating procedures. It is a prevalent method employed to safeguard them against corrosion, enhance their visual appeal, or comply with particular industry standards. The process consists of an initial step of diligently cleaning the pipes to eliminate any dirt, grease, or rust. Subsequently, a primer is applied, followed by the desired paint or coating. The selection of paint or coating is contingent upon the envisioned purpose of the pipes. For instance, epoxy coatings are frequently utilized for water or wastewater pipelines, while high-temperature resistant coatings are employed for pipes utilized in industrial environments. In conclusion, the act of painting or coating steel pipes has the potential to augment their resilience and overall performance.

- Q: How can seamless steel tubes be produced?

- The material of rolling seamless tube is round tube blank, and the billet is processed by cutting machine to grow about 1 meters, and sent to the furnace by conveyor belt. The billets are heated into a furnace and the temperature is about 1200 degrees celsius. The fuel is hydrogen or acetylene. The temperature control in the furnace is a key problem. When the round billet is released, it should be punched through the pressure piercer. The most common punching machine is a cone roll piercer, which has high production efficiency, good product quality, large perforation and expanding diameter, and can be used in various steel grades. After the perforation, the round tube blank has been successively rolled, rolled or squeezed by three rollers.

- Q: How do you calculate the weight of a steel pipe?

- In order to determine the weight of a steel pipe, one must possess knowledge of the pipe's dimensions, specifically the outer diameter (OD), wall thickness, and length. Initially, one must ascertain the cross-sectional area of the pipe. This can be accomplished by subtracting the inner diameter (ID) from the outer diameter (OD) and dividing the outcome by 2 to acquire the radius. Subsequently, the formula A = πr^2 can be employed to compute the area. Following this, it is necessary to multiply the cross-sectional area by the length of the pipe to obtain the volume. The formula for volume is V = A * L, where A denotes the cross-sectional area and L signifies the length. Lastly, to determine the weight of the steel pipe, one must multiply the volume by the density of steel. The density of steel generally falls around 7850 kilograms per cubic meter (kg/m^3) or 0.2836 pounds per cubic inch (lb/in^3). The formula for weight is W = V * ρ, where V represents the volume and ρ denotes the density of steel. It is crucial to note that if one is employing different units, a conversion is imperative to match the units of the density. For instance, if the length is in feet and the density is in pounds per cubic inch, the length must be converted to inches prior to conducting the calculations. Always remember to thoroughly verify your measurements and calculations to ensure precision.

Send your message to us

SPIRAL STEEL PIPE 60‘‘ ASTM API LARGE DIAMETER PIPE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords