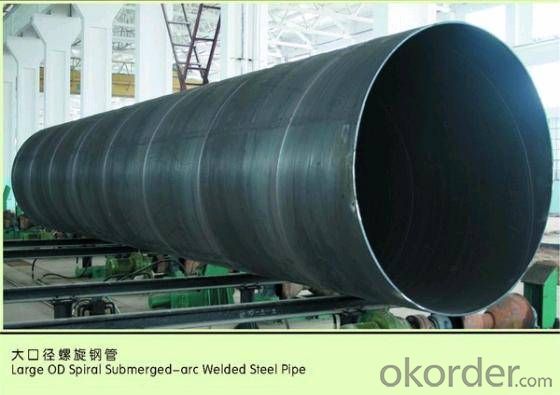

SPIRAL STEEL PIPE 56‘‘ ASTM API LARGE DIAMETER PIPE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail: | standard export packing or as customer's requirement |

Delivery Detail: | within 10 - 30 days |

Specifications

Spiral Welded Steel Pipes and Tubes

1.Material:Q195-Q235

2.Length:1-12m

3.WT:1.0-14mm

4.O.D.:20-273mm

Spiral Welded Steel Pipes and Tubes

Product Description:

1.Material : Q235,Q345,L245,L290,L360,L415,L450,L485,GrB,X42,46,X52,X56,X60,X65,X70,X80,X100

2,Standard: SY/T5037-2000,GB/T9711-2011,API Spec 5L PSL1/PSL2,ASTM A252\A53,ISO3183,DIN17172,EN10217,JIS G3457,AWWA C200,ASTM A139,ASTM A671,ASTM A672

3.Wall thickness: 3.0mm-30mm

4.Outer diameter: φ168mm-3020mm

5,Length: 5m-12m or as your requirement

6,Corrosion protection standard: DIN30670,DIN30671, AWWAC210, AWWA C203, SY/T0413-2002,SY/T0414-2002

7,Application: Oil, gas, natural gas, water pipe, thermal electricity pipe, steel structure engineering, etc

Q195-q345 Material Steel Pipe's Materials

Elements | Chemical Compsition% | Mechanical Property | ||||||

C% | Mn% | S% | P% | Si% | Yield Point (Mpa) | Tensile Strength(Mpa) | Elongation | |

Q195 | 0.06-0.12 | 0.25-0.50 | <0.050< span=""> | <0.045< span=""> | <0.030< span=""> | >195 | 315-430 | 32-33 |

Q215 | 0.09-0.15 | 0.25-0.55 | <0.05< span=""> | <0.045< span=""> | <0.030< span=""> | >215 | 335-450 | 26-31 |

Q235 | 0.12-0.20 | 0.30-0.70 | <0.045< span=""> | <0.045< span=""> | <0.030< span=""> | >235 | 375-500 | 24-26 |

Q345 | <0.20< span=""> | 1.0-1.6 | <0.040< span=""> | <0.040< span=""> | <0.55< span=""> | >345 | 470-630 | 21-22 |

- Q: How do you determine the maximum allowable stress for a steel pipe?

- Several factors need to be taken into account in order to determine the maximum stress that a steel pipe can withstand. The type of steel used in the pipe is of utmost importance, as different types have varying mechanical properties and strengths. Additionally, the dimensions and thickness of the pipe are significant factors in determining its maximum stress capacity. Generally, thicker pipes have higher stress limits compared to thinner ones. Furthermore, it is crucial to consider the operating conditions that the pipe will be exposed to. This includes the temperature, pressure, and the nature of the fluid flowing through the pipe. These conditions can greatly impact the maximum stress that the pipe can tolerate. For instance, high temperatures or corrosive fluids can weaken the steel and reduce its strength. Engineers typically rely on industry standards and codes, such as the ASME Boiler and Pressure Vessel Code and the API standards, to determine the maximum stress limit. These standards provide guidelines and formulas for calculating the maximum stress based on the material properties, dimensions, and operating conditions of the pipe. It is important to emphasize that determining the maximum stress limit is a critical step in ensuring the structural integrity and safety of the steel pipe. It requires a comprehensive understanding of the materials, design considerations, and industry standards. Therefore, it is advisable to seek guidance from experienced engineers or professionals who specialize in piping design and analysis to accurately determine the maximum stress that a steel pipe can withstand.

- Q: How are steel pipes marked for identification and traceability?

- Steel pipes are typically marked for identification and traceability through various methods such as stenciling, stamping, or laser engraving. This marking process involves the application of unique codes, numbers, or logos on the surface of the pipes. These markings serve as crucial identifiers, enabling manufacturers, suppliers, and users to track and trace the pipes throughout their lifecycle, ensuring quality control, proper maintenance, and adherence to industry standards.

- Q: What are the common fittings and accessories used with steel pipes?

- Some common fittings and accessories used with steel pipes include couplings, elbows, tees, reducers, flanges, and valves. Additionally, accessories such as pipe hangers, brackets, clamps, and gaskets are often used to support and secure the pipes.

- Q: Can steel pipes be insulated for thermal efficiency?

- Yes, steel pipes can be insulated for thermal efficiency. Insulating steel pipes helps to reduce heat loss or gain, ensuring better energy efficiency and cost savings. The insulation material, such as foam or mineral wool, is typically wrapped around the pipe to create a barrier that minimizes heat transfer.

- Q: What connections are there for concrete filled steel tubular column foundations?

- Strengthening ring joint is a more common in the construction of steel pipe concrete column construction, it is to beam column connection through the upper and lower plate reinforcing ring bending force transmission way is through two to strengthen the uniform arrangement between the rings radial ribs and rib structure to connect with the ring the pipe wall at the top of the plate, so as to transfer the shear stress, so as to strengthen the thickness and improve the quality of connection engineering advantage. In the process of engineering construction, according to the construction principle of longitudinal reinforcement of Deng Qiang to control, so that the smaller width of not less than the replacement of the width of the connecting plate 70%, also need to be given due attention in the form of node selection

- Q: Are steel pipes suitable for underground mining applications?

- Yes, steel pipes are suitable for underground mining applications. Steel pipes have been widely used in the mining industry for various purposes such as water supply, ventilation, and conveyance of materials. The strength and durability of steel pipes make them suitable for the harsh and demanding conditions of underground mining. Steel pipes are known for their high tensile strength, which allows them to withstand the pressure and stress exerted by the surrounding rock and earth in underground mining operations. They can handle heavy loads, making them suitable for transporting materials and supporting structures in mining tunnels. Additionally, steel pipes are resistant to corrosion, which is crucial in underground mining where moisture and various chemicals are present. Their corrosion resistance ensures the longevity and reliability of the pipes, reducing the need for frequent replacements and maintenance. Furthermore, steel pipes can be easily welded and joined, allowing for customization and flexibility in designing underground mining systems. They can be adapted to various shapes and sizes to meet specific mining requirements. In conclusion, steel pipes are highly suitable for underground mining applications due to their strength, durability, corrosion resistance, and versatility. They have been proven to be effective in supporting mining operations and ensuring the safety and efficiency of underground mining processes.

- Q: How do you repair a damaged steel pipe?

- To repair a damaged steel pipe, you can follow a few steps. First, identify the extent of the damage, such as cracks or holes. Next, clean the damaged area using a wire brush or sandpaper to remove any rust, debris, or old paint. Then, apply a suitable epoxy or sealing compound to seal the crack or hole. For larger damages, welding or brazing may be necessary. Finally, ensure the repaired area is dry and properly cured before testing the pipe for leaks or further issues.

- Q: Can steel pipes be used for geothermal systems?

- Yes, steel pipes can be used for geothermal systems. Steel pipes are commonly used in geothermal systems due to their durability, high strength, and resistance to corrosion. They can effectively handle the high temperatures and pressures associated with geothermal operations, making them a reliable choice for transporting geothermal fluids. Additionally, steel pipes are readily available and cost-effective, making them a practical option for geothermal system installations.

- Q: How are steel pipes used in construction?

- Steel pipes are commonly used in construction for various purposes such as structural support, plumbing, and transportation of fluids and gases. They are used in building frameworks, bridges, and underground infrastructure, providing strength, durability, and flexibility. Steel pipes are often employed in plumbing systems for water supply and drainage. Additionally, they serve as conduits for conveying gas, oil, and other substances. Their versatility and strength make steel pipes an essential component in modern construction projects.

- Q: What are the different methods of wrapping steel pipes for corrosion protection?

- There are several methods used for wrapping steel pipes to provide corrosion protection. These methods include the use of tapes, shrink sleeves, liquid coatings, and powder coatings. Each method has its advantages and disadvantages, and the choice of wrapping method depends on factors such as the environment, the required level of protection, and the budget.

Send your message to us

SPIRAL STEEL PIPE 56‘‘ ASTM API LARGE DIAMETER PIPE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords